Choosing the right bump stop shims helps you get the best ride for your vehicle. You need to match the shims to your car and how you drive. The correct bump stop shims protect your suspension from damage. They also improve comfort, keep you safer, and boost performance. If you use [“bump stop shims”] that fit your needs, you make your driving experience smoother and more reliable.

What Are Bump Stop Shims?

Definition of Bump Stop Shims

You might wonder what bump stop shims are and why they matter for your car. Bump stop shims are thin, strong pieces that you place between your vehicle’s suspension parts and the bump stops. You use them to adjust how soon the bump stops engage when your suspension moves up and down. This small change can make a big difference in how your car handles bumps, heavy loads, or rough roads.

Bump stop shims come in different materials. Each material has its own level of durability and performance. Here is a table to help you compare the most common materials:

| Material | Durability Characteristics |

|---|---|

| Urethane | More durable than regular rubber or microcellular foam |

| Microcellular Foam | Wears out quicker; does not survive hard impacts |

| Air / Hydraulic | Uses nitrogen gas for compressibility; provides progressive firmness |

You can also find shims made from rubber or polyurethane. Urethane resists water, oil, and chemicals, so it lasts longer. Microcellular foam feels soft but wears out faster. Air or hydraulic types use gas to give a smooth, adjustable response.

How Bump Stop Shims Work with Bump Stops

Bump stops protect your suspension system. They act like a cushion, stopping the shock absorber from hitting the end of its travel. When you drive over a big bump or carry a heavy load, bump stops compress and soften the impact. This keeps your car safe and comfortable.

Bump stop shims let you control when the bump stops start working. By adding or removing shims, you change the point where the suspension meets the bump stop. This adjustment helps you fine-tune your ride for daily driving, off-road trips, or carrying extra weight.

Tip: If you want your suspension to handle rough roads better, try using bump stop shims to adjust the timing of your bump stops. This simple step can protect your car and improve your driving experience.

Why Bump Stop Shims Matter for Your Vehicle

Protecting Your Suspension with Bump Stops

You want your vehicle’s suspension to last as long as possible. Bump stops play a big role in protecting your suspension from damage. When you drive over bumps or potholes, bump stops limit how far the suspension can move. This keeps metal parts from hitting each other and stops the axle from moving too far upward. You also avoid your tires rubbing against the fenders on rough roads. Here are some ways bump stops protect your vehicle:

- They limit the movement of suspension parts when you hit bumps or holes.

- They act as a buffer, making your ride more comfortable.

- They prevent metal-to-metal contact between the suspension and the frame.

- They add extra protection and shock absorption when the suspension bottoms out.

- They stop the axle from moving up too much, which keeps tires from rubbing against the body.

By using bump stop shims, you can adjust when these bump stops start working, giving your suspension even more protection.

Improving Ride Quality and Handling

You want your ride to feel smooth and safe. Bump stops help with this by absorbing energy when your suspension compresses. Some bump stops, like hydraulic ones, manage energy very well and give you a softer ride. They also control how your suspension moves up and down, which helps your car handle better. Take a look at this table to see how bump stops improve your ride:

| Feature | Description |

|---|---|

| Energy Absorption | Hydraulic bump stops absorb energy during impacts for a smoother ride. |

| Controlled Damping | They control how the suspension compresses and rebounds, improving handling. |

| Spring Rate Variation | They start soft and get stiffer, which boosts performance and comfort. |

When you use bump stop shims, you can fine-tune these effects to match your driving style.

Customizing Performance for Your Needs

Every driver has different needs. Some people drive on smooth roads every day. Others go off-road or carry heavy loads. Customizing your bump stops with shims lets you change how your suspension works. You can adjust things like suspension travel, ride comfort, and how your car handles turns. Here are some ways you can change your vehicle’s performance:

- Adjust suspension travel for more comfort or better control.

- Change handling to reduce understeer or oversteer.

- Limit body roll to keep your car steady in turns.

- Improve how your tires grip the road by changing how weight moves between the front and rear.

When you use bump stop shims, you get more control over your vehicle’s performance. You can make your ride smoother, safer, and better suited to your needs.

Step 1: Identify Your Vehicle’s Needs and Driving Conditions

Daily Driving vs. Off-Road or Heavy Load

You need to think about how you use your vehicle before choosing bump stop shims. Your driving style and the places you drive make a big difference. If you drive on city streets or highways most of the time, you want a smooth and comfortable ride. Bump stops help protect your suspension and make your ride softer when you hit small bumps or potholes.

If you drive off-road or carry heavy loads, your needs change. Off-road bump stops work best for rough terrain and heavy vehicles. Hydraulic off-road bump stops are recommended for vehicles over 5,000 lbs. They absorb more energy and can be adjusted for your vehicle’s weight and how you use it. You need stronger bump stops when you haul heavy loads because they help your suspension handle extra pressure. Here are some key differences:

- Off-road bump stops give better energy absorption for rough terrain.

- Hydraulic off-road bump stops work well for heavy vehicles and extreme conditions.

- Daily driving needs less strict bump stop requirements but still benefits from comfort and protection.

- Bump stops prevent metal parts from touching, which is important for all driving styles.

- Heavy loads need bump stops that can handle extra force and keep your suspension safe.

Tip: If you use your vehicle for both daily driving and off-road adventures, choose bump stops that balance comfort and strength.

Considering Ride Height and Suspension Travel

Ride height and suspension travel affect how you pick bump stop shims. You need to know how high your vehicle sits and how much the suspension moves up and down. If you change your ride height by adding spacers, you might need extended bump stops or extra components. This helps your suspension work well with the new setup.

Bump stops do not change when you adjust ride height, but you must check if your suspension travel matches your needs. If you use linear rate springs, improper ride height can reduce bump or rebound travel. You want to select bump stop shims that fit your vehicle’s ride height and suspension travel. This keeps your suspension safe and working smoothly.

- Adding spacers for more height may require extended bump stops.

- Make sure your suspension travel matches your driving needs.

- Pick bump stop shims based on your vehicle’s ride height and how much the suspension moves.

Note: Always measure your suspension travel and ride height before choosing bump stop shims. This helps you avoid problems and keeps your vehicle performing well.

Step 2: Check Your Current Bump Stops and Shims

Inspecting for Wear, Damage, or Compatibility

You should always check your bump stops and shims before making any changes to your suspension. Start by looking for signs of wear or damage. Damaged bump stops can make your ride uncomfortable, especially on rough roads. If you notice your trailer swaying or your vehicle leaning during turns, these are warning signs. Suspension sag under heavy loads also means your bump stops may need replacement.

Here are some common signs that show you need to replace your bump stops or shims:

- Your ride feels rough or uncomfortable on uneven surfaces.

- You see your trailer swaying more than usual.

- The suspension sags when you carry heavy loads.

- The vehicle leans or rolls too much during turns.

If you spot any of these problems, you should inspect your bump stops and shims closely. Make sure they fit well and have no cracks or signs of wear. This step helps you avoid bigger suspension issues later.

Assessing Suitability for Your Suspension Setup

You need to make sure your current shims and bump stops match your suspension setup. Different setups, like standard or off-road bump stops, have unique needs. Use the table below to compare important factors:

| Consideration | Bump Stops | Bump Springs |

|---|---|---|

| Durability | Do not perform well in extreme heat | Generally last longer |

| Height Changes | Settles over time, affecting engagement point | N/A |

| Engagement Point | Requires more travel as height decreases | N/A |

Changing even one shim can change how your suspension feels. Proper testing is important. You should not guess when tuning your suspension. A shock dyno gives you the most accurate results. This tool helps you see how your shims and bump stops work together.

Tip: Always test your setup after making changes. This ensures your suspension works safely and gives you the best ride.

Step 3: Determine the Right Size and Material for Bump Stop Shims

Measuring for Proper Fit and Clearance

You need to measure carefully before you choose bump stop shims. The right size makes sure your suspension works as it should. Start by checking the space between your suspension parts and the bump stops when your vehicle is at rest. Use a ruler or caliper to get an accurate measurement. Write down the gap. This helps you pick a shim that fits well and does not cause problems.

Think about the thickness of the shim. The thickness should match the depth of the space you want to fill. If you use a shim that is too thick, your suspension may bottom out too soon. If the shim is too thin, it may not give enough support. Always check the clearance after you install the shim. Make sure nothing rubs or gets pinched.

Shims come in different shapes. You can find flat blocks, U-shapes, and wedges. Each shape works best for certain setups. Flat shims are common for most vehicles. U-shaped and wedge shims help in special cases where you need to fit around other parts.

When you pick a shim, look at these important points:

- The size must match the gap in your suspension.

- The shape should fit your suspension design.

- The shim must not touch or interfere with moving parts.

Tip: Always double-check your measurements before you buy or install shims. This helps you avoid costly mistakes and keeps your suspension safe.

Choosing the Best Material for Your Application

The material of your bump stop shims affects how long they last and how well they work. You want a material that matches your driving needs. Factory bump stops often use rubber or microcellular foam. These materials work for daily driving but may wear out faster in tough conditions.

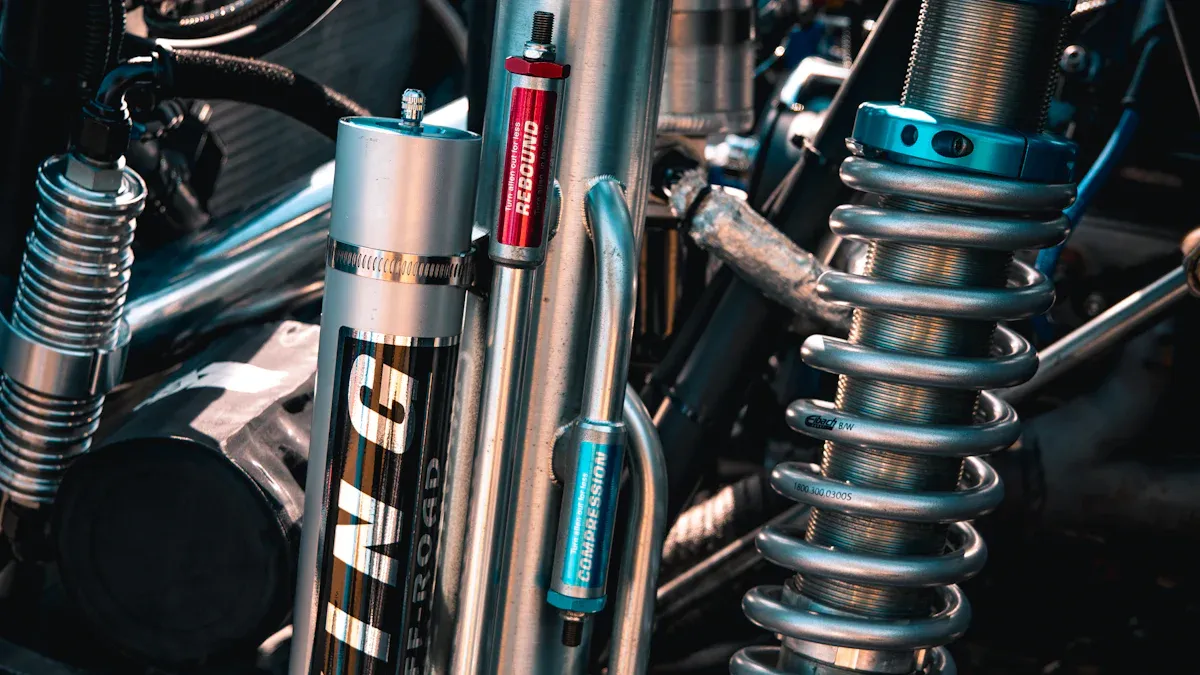

For high-performance or off-road use, you need stronger materials. Polyurethane is a popular choice in aftermarket shims. It lasts longer than rubber and handles rough roads better. Hydraulic bump stops use fluid to absorb energy. This gives you better control and comfort on rocky or uneven ground. Some off-road bump stops, like Timbren Active Off-Road Bumpstops, use natural rubber to handle harsh impacts.

Here are some key features to look for in shim materials:

- Durability: Polyurethane and hydraulic types last longer under stress.

- Compressive Strength: The material must handle the weight of your vehicle without crushing.

- Creep Resistance: Good shims do not change shape over time.

- Impact Resistance: Off-road shims need to survive hard hits.

- Compatibility: The material should not react with other parts of your suspension.

You also want to make sure your shims meet industry standards. Many shims follow ASTM, SAE, or DIN guidelines. These standards make sure the shims have the right strength, shape, and safety features.

Here is a table to help you compare common shim materials:

| Material | Best Use Case | Key Features |

|---|---|---|

| Rubber | Daily driving | Soft, absorbs small bumps |

| Microcellular Foam | Light-duty, comfort | Soft, wears out faster |

| Polyurethane | Performance, off-road | Durable, resists oil and water |

| Hydraulic | Extreme off-road | Uses fluid, absorbs big impacts |

| Natural Rubber | Off-road, heavy impacts | Flexible, handles harsh hits |

| Metal (Steel, Alloy) | Heavy-duty, custom setups | High strength, less common in shims |

Note: Always choose a material that matches your driving style and the conditions you face most often. If you drive off-road or carry heavy loads, pick a material with high impact and compressive strength.

When you select the right size and material, you help your bump stops work better. This keeps your suspension safe and your ride comfortable.

Step 4: Match Bump Stop Shims to Your Suspension Setup

Understanding Different Suspension Types

You need to know your vehicle’s suspension type before you choose bump stop shims. Each suspension system works in a different way. Coil spring suspensions are common in many cars and trucks. They use springs to absorb bumps and keep your ride smooth. Leaf spring suspensions appear often on trucks and heavy vehicles. These use stacked metal strips to support more weight. Air suspensions use air-filled bags instead of metal springs. This type lets you adjust ride height and comfort with the push of a button.

Each suspension type needs a different approach when you pick shims. Coil spring systems often need shims that fit tight spaces. Leaf spring setups may need larger or thicker shims for extra support. Air suspensions need shims that do not block the air bags or lines. Always check your suspension type first. This helps you find the right shim size and shape for your vehicle.

Tip: Look at your owner’s manual or ask a technician if you are not sure about your suspension type.

Selecting Shims for Your Intended Use

You must match your bump stop shims to how you use your vehicle. If you race, tow, or drive off-road, you need to think about the force your suspension will face. The length and size of your bump stop shims change how much force they can handle. Shorter bump stops give more force in a small space. Longer bump stops spread the force out and feel softer.

Here is a table to help you see the difference:

| Bump Stop Length | Force at 0.5 inches |

|---|---|

| Shortest (red) | Most force |

| Medium | Moderate force |

| Longest | Least force |

If you race, you want a short bump stop with a small size. This gives you quick response and better control. For towing or carrying heavy loads, a longer bump stop with a larger size helps absorb more impact and keeps your ride stable. Always choose shims that match your driving needs. This keeps your suspension safe and your ride comfortable.

Note: Test your setup after you install new shims. This helps you make sure your suspension works the way you want.

Step 5: Installation and Upgrade Tips for Bump Stop Shims

Tools Needed for Installation

Before you start, gather the right tools. Using the correct equipment makes the job easier and helps you avoid mistakes. Here are some tools that automotive experts recommend:

- JOES Bump Stop Shims

- Caster camber gauges

- Toe & turn plates

- Sharpies or paint pens

- Shock tools

- Tape and tape measures

- Tire tools

- Wrenches and sockets

- Zip ties

You may notice that the front and back of your vehicle can sit at different heights after installing shims. Always check both ends for proper fit.

Simple Steps for Installing Bump Stop Shims

You can install bump stop shims by following a few clear steps. This process helps you avoid common errors and keeps your suspension working well.

- Assess the gap. Measure the space that needs adjustment. Check for any uneven surfaces.

- Choose and prepare your shim. Pick the right material and thickness. Trim the shim if needed.

- Position the shim. Insert it into the gap. Make sure it lines up correctly, especially if you stack shims.

- Secure the shim. Tighten bolts or screws slowly. For friction-fit shims, tap them gently into place.

- Check alignment. Use a level to confirm everything sits straight. Make small adjustments if needed.

- Trim excess shim material. Cut off any part that sticks out beyond the application.

Take your time with each step. Careful work gives you the best results.

When to Seek Professional Help

Sometimes, installing bump stop shims can get complicated. You should consider professional help in these situations:

- Your vehicle uses bump stops for off-road driving or heavy loads.

- You drive on uneven terrain often.

- The installation seems too complex or you feel unsure.

A professional can make sure the shims fit perfectly and your suspension stays safe. This is important for vehicles that face tough conditions or carry extra weight.

Common Mistakes to Avoid with Bump Stop Shims

Using the Wrong Size or Type

You might think any shim will work, but choosing the wrong size or type can cause problems for your suspension. If you pick a shim that is too thick or too thin, your bump stops may engage too early or too late. This can make your ride rough or even damage your suspension parts. Many drivers overlook the importance of bump stops, especially in motorsport or off-road situations. When you use off-road bump stops, you need to match the shim size to your vehicle’s needs. Failing to tune bump stops correctly can lead to poor handling during acceleration or braking.

Tip: Always measure the gap and check your suspension setup before selecting a shim. Proper tuning helps you get the best performance and comfort.

Ignoring Material Differences

Not all bump stop shims use the same material. Some drivers ignore this and choose whatever is available. This mistake can affect how long your suspension lasts and how well it performs. Rubber shims work for daily driving, but microcellular polyurethane elastomer (MPU) shims offer better durability and flexibility. MPU shims keep their shape at low temperatures and provide consistent performance over time. They act like a progressive spring, getting stiffer as they compress. This helps soften impacts and protects your shock absorbers, especially if you have lowering kits.

- Rubber shims absorb small bumps but wear out faster.

- MPU shims last longer and handle tough conditions better.

- The right material prevents damage and keeps your ride smooth.

Skipping Regular Inspections

You need to check your bump stop shims often. Skipping inspections can lead to unnoticed wear or damage. Over time, shims may crack, compress, or shift out of place. If you do not inspect them, you risk poor suspension performance and possible safety issues. Regular checks help you spot problems early and keep your vehicle running safely.

- Look for cracks, wear, or changes in shape.

- Make sure shims stay in the correct position.

- Replace damaged shims right away.

Note: Regular inspections save you money and keep your suspension working as it should.

When to Upgrade Your Bump Stops and Shims

Signs It’s Time for Replacement or Upgrade

You need to know when your bump stops and shims no longer work well. Old or damaged parts can hurt your suspension and make your ride rough. Look for these signs to decide if you should upgrade or replace your bump stops and shims:

- You hear clunking or banging noises when you drive over bumps.

- Your vehicle sags or leans more than usual, especially with heavy loads.

- You see cracks, splits, or missing pieces on the bump stops or shims.

- The ride feels harsh, or you notice more vibration from the road.

- Your tires rub against the fenders or wheel wells.

If you spot any of these problems, check your suspension right away. Worn bump stops and shims can lead to bigger issues, like damaged shocks or springs. You should upgrade or replace these parts before they cause more trouble.

Tip: Inspect your bump stops and shims every time you change your oil or rotate your tires. Regular checks help you catch problems early.

Benefits of Upgrading to Quality Bump Stop Shims

When you choose to upgrade or replace your bump stop shims with high-quality options, you get many benefits. Quality shims protect your suspension and improve your driving experience. Here are some reasons to pick better bump stop shims:

| Benefit | What You Gain |

|---|---|

| Better Ride Comfort | Softer landings over bumps and potholes |

| Improved Safety | Less risk of suspension damage or tire rubbing |

| Longer Suspension Life | Less wear on shocks, springs, and bushings |

| Custom Performance | Shims that match your driving style |

You also get more control over how your vehicle handles. Quality shims let you fine-tune your suspension for daily driving, towing, or off-road trips. You spend less on repairs because your suspension lasts longer. Upgrading to the right shims makes your ride smoother and safer every day.

Where to Find Quality Bump Stop Shims and Expert Support

Trusted Sources and Brands for Bump Stop Shims

You want to buy bump stop shims from sources you can trust. Reliable brands use strong materials and follow strict quality standards. When you choose a trusted supplier, you protect your vehicle and get better performance. Look for companies with certifications like TS17009. This certificate shows that the company meets international standards for auto parts.

Here are some ways to spot a trusted source:

- The company has a good reputation with customers in many countries.

- The supplier offers detailed product information and testing reports.

- You see clear photos and specifications for each shim.

- The brand exports products to places like the USA, Europe, Japan, and Australia.

You can use this table to compare what trusted brands offer:

| Brand Feature | Why It Matters |

|---|---|

| Certification | Ensures quality and safety |

| Export Experience | Shows reliability and global trust |

| Technical Support | Helps you choose the right product |

| Product Range | Gives you more options for your needs |

Tip: Always check for customer reviews and ask for technical details before you buy. This helps you avoid low-quality parts.

Getting Expert Advice and Technical Support from Max

You may need help when choosing or installing bump stop shims. Max gives you expert advice and technical support. The team at Max has years of experience in auto parts, especially shock absorbers and suspension systems. You can ask questions before you order. You get help during installation and after your purchase.

Max’s engineers can guide you through the selection process. They help you match shims to your vehicle and driving style. You can request inspection reports like PPAP, RT, or UT. Max uses advanced testing equipment to check every product. You get support for OEM and ODM orders, so you can customize parts for your needs.

If you have a problem, Max solves it quickly. The team cares about your satisfaction and wants you to have a smooth experience. You can contact Max for advice, technical support, or product recommendations.

Note: When you choose Max, you get more than just auto parts. You get a dedicated team that supports you every step of the way.

You can choose the right bump stop shims by following these simple steps. First, check your vehicle’s needs. Next, inspect your current bump stops and shims. Then, measure for the correct size and pick the best material. Match the shims to your suspension setup and install them carefully. Quality bump stop shims help keep you safe and improve your ride. If you need help or want product recommendations, reach out to Max’s expert team.

Remember, taking action today protects your suspension and boosts your driving experience.

FAQ

What do bump stop shims actually do?

Bump stop shims let you adjust when your suspension bump stops engage. You can fine-tune your ride comfort and protect your suspension from harsh impacts. Shims help you match your vehicle’s setup to your driving needs.

How often should I check or replace bump stop shims?

You should inspect your bump stop shims every time you change your oil or rotate your tires. Look for cracks, wear, or shifting. Replace them if you see damage or if your ride feels rougher than usual.

Can I install bump stop shims myself?

Yes, you can install bump stop shims with basic tools like wrenches and a tape measure. If you feel unsure or have a complex suspension, ask a professional for help. Safety always comes first.

Which material is best for bump stop shims?

Polyurethane works well for most drivers. It lasts longer than rubber and resists oil and water. If you drive off-road or carry heavy loads, consider hydraulic or natural rubber shims for extra strength.

Where can I get help choosing the right shims?

You can contact Max’s expert team for advice. They offer technical support, product recommendations, and help with installation. Reach out by email or phone for fast answers.