Powder metallurgy manufacturing is a superior process for the modern automotive industry. This technique creates high-performance parts and allows for complex shapes that are difficult to achieve with other methods. The powder metallurgy process delivers components with high precision, improving overall engine performance and efficiency.

The result is exceptional durability and cost-effectiveness. The parts produced by powder metallurgy create stronger, lighter, and more reliable engine components for the vehicles of tomorrow.

The Key Advantages of Powder Metallurgy in Engine Design

Powder metallurgy (PM) provides significant engineering benefits for modern engine manufacturing. The process excels in creating parts with intricate geometries, tight tolerances, and reduced weight. These advantages of powder metallurgy translate directly into improved engine efficiency, reliability, and performance, making it a cornerstone of advanced automotive production.

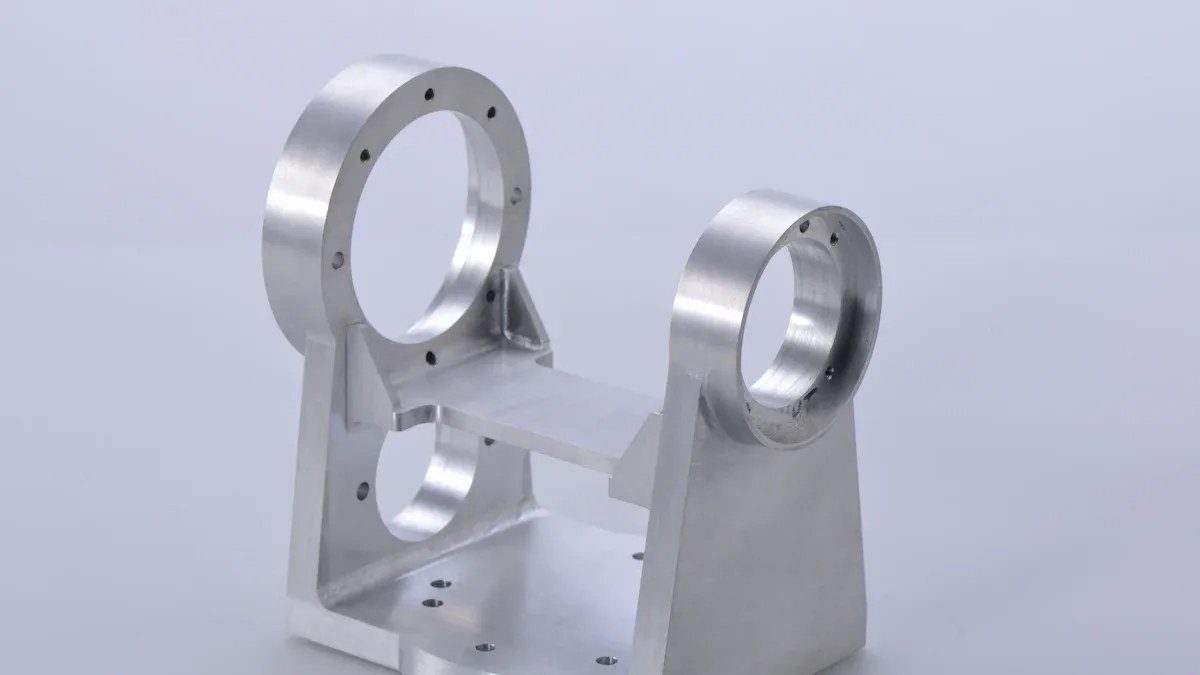

Achieving Net-Shape Complexity

The powder metallurgy process specializes in producing parts at or very near their final dimensions. This is known as “net-shape” or “near-net-shape” manufacturing. It allows engineers to design complex shapes that are often impossible or prohibitively expensive to create with traditional subtractive methods like machining. This capability is crucial for modern engines, which rely on sophisticated components to function.

This manufacturing process is also remarkably efficient. It utilizes over 97% of the raw material, drastically reducing the waste common in other methods. This efficiency eliminates many costly and time-consuming secondary machining operations. The result is a streamlined production cycle that delivers high-quality parts consistently.

Key automotive components exclusively produced using this method include:

- Porous, self-lubricating bearings

- Engine filters

- Soft and hard magnetic components

- Intricate variable valve timing (VVT) system parts

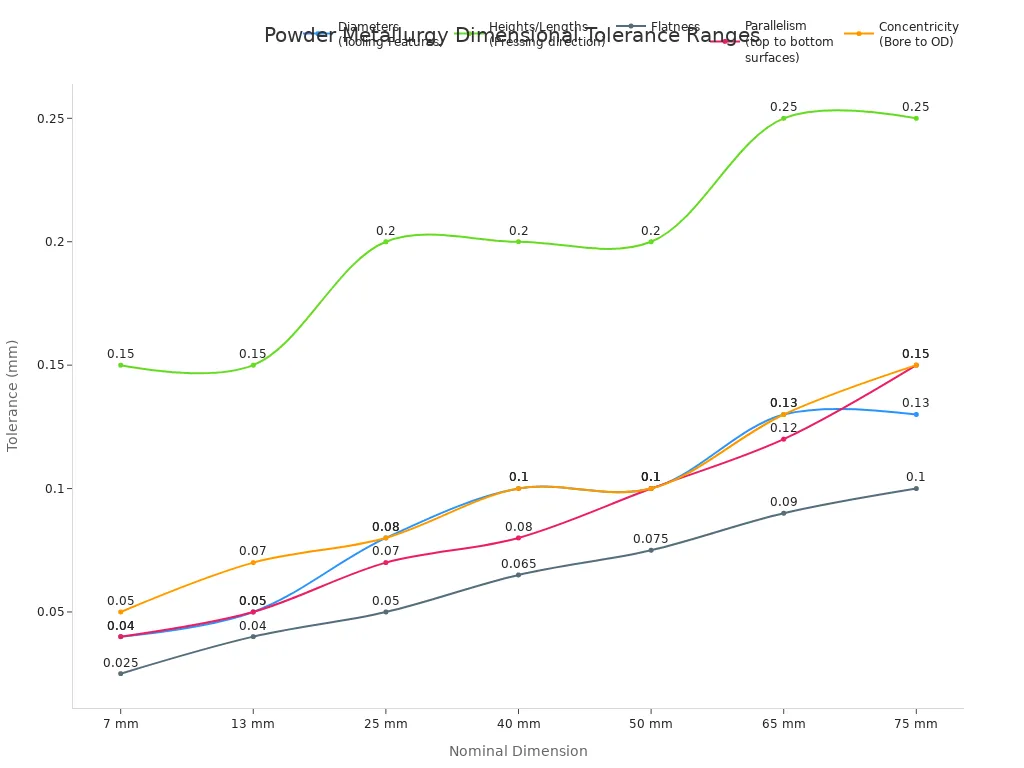

Ensuring Exceptional Dimensional Accuracy

Consistency is critical in mass production for the automotive industry. The powder metallurgy process delivers exceptional dimensional repeatability from the first part to the last. This ensures that every component meets strict engineering specifications. The method provides high precision for critical features, leading to better fit and function within an engine assembly.

The typical dimensional tolerances achievable with powder metallurgy demonstrate its reliability. The table below outlines the standard tolerances for various part features, which are influenced by material choice and sintering parameters.

| Feature | 7 mm | 13 mm | 25 mm | 40 mm | 50 mm | 65 mm | 75 mm |

|---|---|---|---|---|---|---|---|

| Diameters | 0.04 mm | 0.05 mm | 0.08 mm | 0.10 mm | 0.10 mm | 0.13 mm | 0.13 mm |

| Heights/Lengths | 0.15 mm | 0.15 mm | 0.20 mm | 0.20 mm | 0.20 mm | 0.25 mm | 0.25 mm |

| Parallelism | 0.040 mm | 0.05 mm | 0.07 mm | 0.08 mm | 0.10 mm | 0.12 mm | 0.15 mm |

| Concentricity | 0.05 mm | 0.07 mm | 0.08 mm | 0.10 mm | 0.10 mm | 0.13 mm | 0.15 mm |

While CNC machining can achieve even tighter specifications for specialized applications, the PM process provides excellent accuracy for high-volume production. It avoids the slight dimensional changes that can occur during the cooling phase of other manufacturing techniques.

Reducing Component Weight Without Sacrificing Strength

The production of lightweight parts is a primary goal for enhancing vehicle fuel efficiency and performance. The advantages of powder metallurgy shine in this area by enabling the use of advanced, lightweight materials without compromising structural integrity.

Engineers use specialized metal powders, such as aluminum and titanium alloys, to create strong yet lightweight components.

- Aluminum Alloys: These are valued for their low density and high strength-to-weight ratio. They are ideal for creating parts like sprockets and rotors. For example, an aluminum cam phaser sprocket made with PM weighs only 450 grams, which is half the weight of a 900-gram sintered iron equivalent.

- Titanium Alloys: These offer an exceptional combination of strength, corrosion resistance, and low weight. They are used for high-performance automotive parts where durability is paramount.

A key benefit of using these lightweight metals in the PM process is achieving less weight with the same or greater strength. This technique allows for intricate designs that can cut the weight of components by up to 50% while fully maintaining their structural integrity.

This focus on lightweighting makes powder metallurgy an essential tool for building the efficient and powerful engines of the future.

Powder Metallurgy Manufacturing for Superior Performance

The powder metallurgy manufacturing process delivers more than just complex shapes; it unlocks a new level of component performance. Engineers can precisely control material properties to meet the extreme demands of modern engines. This customization results in components that are stronger, more durable, and better at managing heat, directly boosting overall engine efficiency and reliability.

Customizing Material Blends for High-Stress Roles

Powder metallurgy offers unparalleled control over material composition. The process allows engineers to create custom metal powder blends, fine-tuning the final part’s characteristics for specific high-stress roles. This versatility enables the creation of components with tailored strength, optimized load-bearing capacity, and enhanced hardness.

For example, a specialized powder metal alloy for high-stress automotive applications like transmission gears contains 0.85% Molybdenum and 0.25% Carbon. This specific blend achieves a high density of 7.25 g/cm³, providing the durability needed for demanding drivetrain functions. The ability to customize alloys allows for the creation of parts with superior mechanical properties.

The table below highlights how different metal powders are selected for specific engine part applications based on their key properties.

| Metal Powder Type | Key Properties | Engine Part Application |

|---|---|---|

| Steel (e.g., AISI 4600) | Superior strength, wear resistance | Connecting rods, camshafts |

| Nickel-based (e.g., Inconel 625) | Exceptional resistance to high temperatures | Turbocharger housings, exhaust manifolds |

| Molybdenum (e.g., Mo-Ni) | Exceptional strength at elevated temperatures | Piston rings, valve seats |

| Titanium (e.g., Ti-6Al-4V) | Ultimate strength-to-weight ratio | High-end racing components |

| Cobalt-Chromium (e.g., CoCrMo) | Excellent wear resistance | Valve tappets, cam followers |

Enhancing Wear Resistance and Fatigue Strength

Engine components face constant friction and stress. The powder metallurgy manufacturing process addresses this challenge by creating parts with excellent wear resistance and fatigue strength. This durability is often enhanced through specialized secondary surface treatments that harden the component’s exterior while keeping the core tough and ductile.

These treatments create a protective layer that significantly extends the life of the part, ensuring long-term performance and reliability in the demanding automotive environment.

Several surface treatments are applied to powder metallurgy parts:

- Stream Treatment (Blackening): This process exposes iron-based parts to high-temperature steam. It forms a hard ferroferric oxide layer, increasing surface hardness to over 40 HRC.

- Phosphate Treatment: A chemical reaction creates a phosphate coating on the part. This layer improves both corrosion protection and wear resistance.

- Heat Treatment: Methods like carburizing and induction hardening are highly effective. Carburizing diffuses carbon into the surface of a part, creating an extremely hard exterior ideal for gears. Induction hardening locally hardens specific areas, perfect for components subjected to high loads.

Improving Thermal Management in High-Temp Zones

Managing heat is critical for engine efficiency and longevity. The powder metallurgy manufacturing process excels at creating components that can withstand and dissipate high temperatures. This is achieved by using advanced materials with high thermal conductivity and by designing parts with optimized shapes for cooling.

Specialized materials like AyontEX Aluminum-Silicon alloys are engineered for high-technology applications. The AyontEX 4632 AlSi alloy, for instance, is used in automotive racing pistons. It enables significant weight reduction while providing the stability and thermal conductivity needed to perform under extreme heat.

A Leap in Thermal Performance A novel aluminum alloy known as TC2000, created through a unique powder metallurgy process, offers up to double the thermal conductivity of conventional cast aluminum. This allows for smaller, lighter cooling systems without sacrificing performance.

This improved thermal management contributes directly to overall engine efficiency. Better heat dissipation allows engines to run at optimal temperatures, which reduces wear on components and improves fuel combustion. In advanced applications, materials like Ceramic Matrix Composites (CMCs) operate at temperatures far beyond the limits of metals. Their superior heat resistance reduces the need for cooling air, allowing more air to be used for thrust and improving fuel economy.

Gaining Economic and Sustainable Powder Metallurgy Benefits

The powder metallurgy manufacturing process delivers significant financial and environmental advantages. This technique provides superior cost-effectiveness and sustainability, making it a strategic choice for modern automotive production. The powder metallurgy benefits extend from raw material savings to lower energy use, creating a highly efficient manufacturing cycle.

Maximizing Material Utilization to Over 97%

One of the greatest powder metallurgy benefits is its exceptional material efficiency. The process utilizes over 97% of the raw metal powder, meaning only 3% becomes scrap. This stands in sharp contrast to traditional subtractive methods like CNC machining, where cutting away from a solid block can waste up to 50% of the material. This high utilization rate is a core advantage, directly lowering the overall part cost. This superior material efficiency makes the production of lightweight parts more economical and sustainable.

Lowering Energy Consumption and Production Costs

Powder metallurgy manufacturing reduces both energy use and production cost. The sintering process operates at lower temperatures than melting metals for casting or forging, conserving significant energy. For example, switching a truck transmission component to this process reduced manufacturing steps from 17 to just six, cutting energy use per part in half. This efficiency translates directly into lower operational expenses. The overall cost-effectiveness is a primary reason industries are adopting this technology.

A Greener Process The powder metallurgy benefits include a smaller environmental footprint. By minimizing waste and reducing energy consumption, the process supports a circular economy and lowers emissions, making it a more sustainable choice for creating automotive components.

Eliminating Costly Secondary Machining Operations

A key economic advantage comes from producing parts at or near their final shape. This near-net-shape capability means there is less machining needed after the initial forming. Eliminating these extra steps saves time, reduces labor, and lowers tooling cost. This streamlined process is one of the most impactful powder metallurgy benefits, ensuring faster production cycles for complex components. This reduction in manufacturing stages is fundamental to the technology’s cost savings and efficiency.

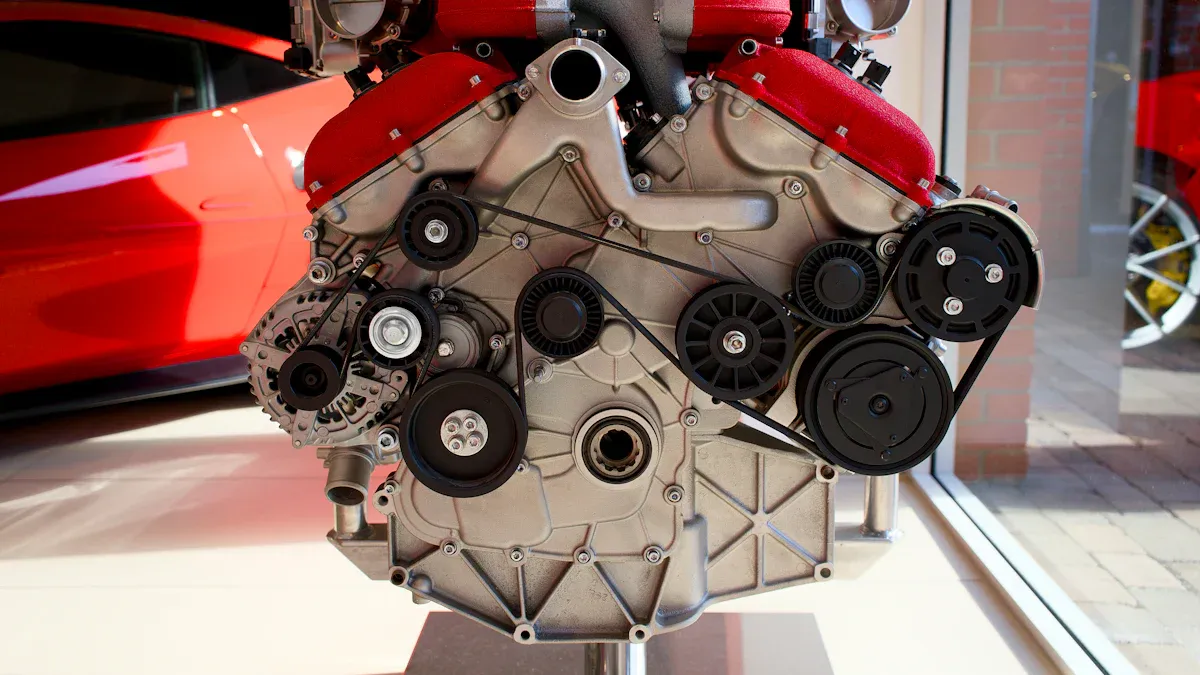

Critical Automotive Applications for Parts Produced by Powder Metallurgy

Powder metallurgy is a key manufacturing process for many critical engine components. Its ability to create strong, complex parts makes it essential for modern automotive applications. Common parts produced by powder metallurgy include:

- Sprockets

- Gears

- Connecting rods

- Camshafts

- Main bearing caps

These components demonstrate the versatility and reliability of the technology in demanding automotive environments.

High-Strength Connecting Rods and Main Bearing Caps

Connecting rods and main bearing caps operate under immense stress inside an engine. Powder metallurgy produces robust components that can handle these forces. Advanced processes enhance the durability of these parts even further. For example, over-burnishing main bearing caps improves their fatigue resistance by 17%. Similarly, using roll-forming for threads can boost thread strength by an impressive 44%, from 71 N-m to 102 N-m. These enhancements create stronger, more reliable engine components for superior performance.

Intricate Variable Valve Timing (VVT) Components

Variable Valve Timing (VVT) systems require components with extremely complex shapes to function correctly. Powder metallurgy excels at producing these intricate parts, such as VVT stators and rotors. The process allows for true three-dimensional magnetic flux paths, which are difficult to achieve with other methods. One automotive supplier successfully uses a PM-related process to finish VVT stators with a highly interrupted bore, meeting a tight 50-micron roundness tolerance. This capability makes PM perfect for high-volume automotive applications that demand precision.

Durable Valve Seats and Camshaft Lobes

Valve seats and camshaft lobes must resist constant wear and high temperatures. These are ideal parts for powder metals because the process creates parts with excellent hardness and durability. Heat treatment further improves the wear resistance of these components, with the hardness of a sintered iron alloy valve seat reaching over 40 HRC. This ensures a long service life in the harsh engine environment.

Sintered Iron Alloy Valve Seat Specifications The table below shows typical properties for these durable parts produced by powder metallurgy.

| Attribute | Value |

|---|---|

| Sintered Density | 6.6-7.0 g/cm³ |

| Sintered Hardness | 65-90 HRB |

| Hardened Hardness | 40 HRC Min. |

| Tolerance | ±0.01 mm |

Powder metallurgy manufacturing delivers superior cost-effectiveness for the modern automotive industry. This process creates components with complex shapes, boosting engine performance and efficiency. The automotive sector benefits from a lower production cost. The parts produced by powder metallurgy are essential for today’s vehicles. These advanced components ensure reliability and reduce overall cost. Adopting this technology is a strategic move for the future of automotive manufacturing. It delivers the high-quality components needed to build the engines of tomorrow. The parts produced by powder metallurgy truly future-proof the industry.

FAQ

What makes powder metallurgy parts so strong?

The strength comes from the sintering process, which bonds metal particles at a molecular level. Custom alloy blends and high compaction pressures create dense, robust components. Secondary treatments like heat treating can further increase surface hardness to over 40 HRC for exceptional durability.

How does powder metallurgy help the environment? ♻️

This process is highly sustainable. It utilizes over 97% of its raw material, drastically reducing waste compared to machining. Sintering also consumes less energy than melting metals for casting, lowering the overall carbon footprint of manufacturing and supporting a circular economy.

Can PM parts handle high temperatures in an engine?

Yes, they excel in high-heat zones. Engineers select specialized materials like nickel-based alloys or advanced aluminum-silicon blends for these applications. These materials offer superior thermal stability and conductivity, ensuring reliability for parts like valve seats and turbocharger components.

Is powder metallurgy a cost-effective process?

Powder metallurgy provides significant cost savings. The near-net-shape manufacturing process eliminates most expensive and time-consuming secondary machining. Combined with minimal material waste, it lowers production costs, especially for complex parts produced in high volumes for the automotive industry.