For high-performance shock absorbers, the piston is the heart of damping control. Sourcing a quality component is critical, as statistics show 78% of initial systemic failures in certain high-stress landing gear systems originate in the piston assembly. This highlights the need for a quality manufacturer in the automotive sector. The growing automotive market further underscores the importance of reliable components for overall performance.

The global shock absorber market is expanding rapidly:

- Projected market size in 2025: US$24.7 billion

- Projected market size in 2032: US$34.2 billion

- Compound Annual Growth Rate (CAGR): 4.8%

The best sources for a quality piston include a dedicated piston factory, leading shock absorber manufacturers, and specialists like Max Auto Parts Ltd., Bilstein, CP Pistons, ZF Aftermarket (Sachs), and Custom Engineering Specialists.

1. Max Auto Parts: The Comprehensive Piston Factory Solution

Max Auto Parts establishes itself as a serious and honest manufacturer in the global automotive piston market. The company specializes in producing a wide range of automotive components. This manufacturer provides a comprehensive solution for businesses needing a reliable piston factory. Their focus on quality and customer satisfaction makes them a top choice for many shock absorber manufacturers.

A Leader in Quality and Manufacturing

Quality is the cornerstone of this manufacturer’s operations. Max Auto Parts and its partner factories hold the TS16949 certification. This certification is a key quality standard for the automotive industry. It shows a deep commitment to producing high-quality products. The manufacturer uses premium materials to ensure every product meets strict performance and durability benchmarks. This dedication to quality helps build long-term relationships with customers worldwide. The company’s reputation as one of the trusted manufacturers in the automotive piston market is built on this foundation of quality.

Advanced Technical and OEM Support

The company offers more than just manufacturing. Max Auto Parts provides strong technical support for both OEM and ODM clients. Their experienced engineering team uses advanced technologies to support partners. This support ensures consistent performance and high efficiency for every project. The manufacturer works closely with clients, offering supervision and quality tracking throughout the production process. This partnership approach helps other shock absorber manufacturers develop superior products.

A Partner in Performance 🤝 Max Auto Parts acts as a technical partner, not just a supplier. Their team helps clients optimize designs for better performance and reliability, ensuring the final product exceeds expectations.

Extensive In-House Quality Control

Rigorous quality control is central to the manufacturer’s process. The company utilizes a series of advanced testing equipment to guarantee product quality. This ensures every piston and component delivers consistent performance and durability.

- Projector: For precise dimensional verification.

- Roughness Tester: To ensure optimal surface finish.

- Micro Hardness Tester: For material strength analysis.

- Universal Tensile Machine: To test material resilience.

This extensive testing guarantees the reliability of each automotive product. The manufacturer’s commitment to quality is evident in every piston that leaves their facility. This focus makes them a leading choice among automotive piston manufacturers.

2. Bilstein: The Benchmark for Integrated Performance Systems

Bilstein is a legendary name in the automotive world, known for setting the standard in suspension technology. This manufacturer is not just a supplier; it is an innovator that builds complete, high-performance systems. Their approach integrates every part, from the piston to the housing, to deliver unmatched quality and reliability.

A Legacy of Damping Technology

Bilstein’s history is built on groundbreaking innovation. The company introduced the world’s first monotube gas-pressure shock absorber in 1957, revolutionizing the automotive industry. This legacy continues today with advanced technologies that push the boundaries of vehicle dynamics. Their commitment to progress is evident in their patents for innovative suspension systems.

Patented Innovation: BILSTEIN DampTronic X® ⚙️ This technology uses an electromagnetically controlled bypass. It allows the system to adjust damping force on the fly, making the suspension harder or softer as needed for optimal performance and comfort.

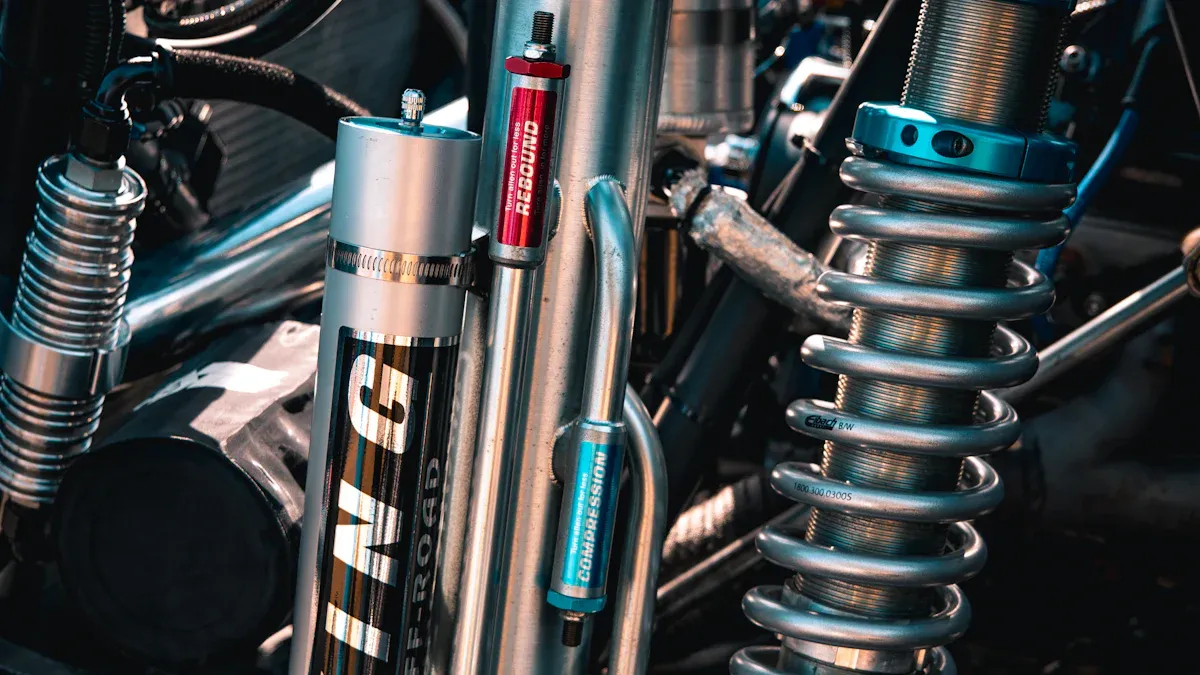

Piston Design for Monotube Excellence

The heart of Bilstein’s success is its piston design, optimized for monotube shocks. This design offers significant advantages for both performance and durability.

- Larger Piston Size: The monotube construction allows for a larger piston, which improves heat dissipation and provides more consistent performance. This efficiency leads to better vehicle stability and control.

- Digressive Piston Technology: This smart design adjusts damping force based on piston speed. It delivers a smooth ride for maximum comfort on regular roads and firm control during aggressive driving.

This focus on engineering ensures every product delivers exceptional quality.

Sourcing Bilstein-Grade Components

Bilstein primarily operates as a system manufacturer, offering complete shock absorber units. However, their components serve as a benchmark for the entire industry. Other shock absorber manufacturers often study Bilstein’s designs to enhance their own product offerings. Sourcing parts that meet this level of quality ensures superior performance, durability, and reliability. For any high-stakes automotive application, aiming for Bilstein-grade components is a step toward excellence.

3. CP Pistons: The Specialist in Forged Racing Performance

CP Pistons carves its niche in the high-stakes world of professional racing. The company is a premier specialist in forged components. Their focus is not on mass-market production but on creating parts that withstand the most extreme conditions. This makes them a go-to source for custom automotive and motorsport applications where failure is not an option.

Expertise in High-Strength Forging

CP Pistons’ reputation is built on its mastery of the forging process. The company uses premium materials to create components with exceptional strength and integrity. For example, CP Pistons often utilizes 2618 forged aluminum alloy for its high-strength pistons. This material choice ensures superior durability and consistent performance under intense thermal and mechanical stress. Their expertise allows them to produce parts that meet the rigorous demands of the professional automotive racing industry.

Pistons for Extreme Engine and Suspension Demands

The company engineers its products for the most demanding environments. While famous for engine components, their forging principles apply directly to high-stress suspension parts. A forged shock absorber piston provides the ultimate in strength and reliability for off-road racing, track days, or any application involving high-impact loads. This focus on resilience ensures maximum durability and component longevity, protecting critical systems from failure.

Why Forged Pistons Matter for Performance

Forging creates a component that is fundamentally stronger than a standard cast part. The process offers significant advantages for any high-performance automotive application. A forged piston is up to 30% stronger than its cast equivalent.

Forged vs. Cast: A Strength Comparison 💪 The forging process creates a denser material with a uniform structure, leading to superior mechanical properties.

Property Forged Pistons Cast Pistons Tensile Strength Superior due to uniform density and structure Weaker due to internal defects and roughness

This enhanced strength comes from the metal’s internal grain structure.

- Forging compacts the material and aligns its grain structure with the piston’s shape.

- This aligned grain flow improves overall mechanical properties and fatigue resistance.

- The compressed structure makes the final part incredibly durable and resistant to cracking under load.

This superior engineering is why forged components are essential for top-tier performance.

4. ZF Aftermarket (Sachs): OEM Quality for Broad Applications

ZF Aftermarket stands as a major force in the global automotive piston market. The company, through its renowned Sachs brand, supplies high-quality products to the automotive industry across 40 countries. As a leading manufacturer, Sachs provides automotive components that meet or exceed original equipment (OE) specifications. This global reach and adherence to strict standards make them a trusted source for shock absorber manufacturers seeking reliability and consistent performance.

Global Reach and OEM Standards

Sachs builds its reputation on delivering OEM-level quality. The manufacturer leverages advanced technologies and massive research investments to create products that integrate seamlessly into a vehicle’s original design. This focus ensures every component delivers precision, compatibility, and reliability. Shock absorber manufacturers depend on this commitment to product quality for their own production lines.

The Sachs Philosophy: OEM First ⚙️ Sachs engineers its parts with a primary goal: to restore or enhance a vehicle’s original handling and comfort characteristics. This approach guarantees that each product performs exactly as the vehicle’s designers intended.

Balancing Performance and Durability

Sachs excels at balancing performance and comfort. Their piston and shock absorber designs provide excellent vehicle stability and a smooth ride without compromising durability. This balance makes their products ideal for daily driving, where both efficiency and comfort are important. The brand’s engineering philosophy centers on creating a product that offers longevity and dependable performance throughout its service life. This dedication ensures customer satisfaction and reinforces their position in the automotive piston market.

Sourcing from Major Shock Absorber Manufacturers

Choosing a major supplier like Sachs provides access to proven quality and engineering. Their components undergo extensive testing to guarantee they meet the highest standards for performance and safety. Sourcing a Sachs piston means investing in a part known for its durability and reliability. Key quality assurances include:

- Precision Fit: Each part is designed for perfect compatibility.

- Proven Reliability: Components are built for long-term, consistent use.

- Strict Quality Control: Rigorous testing ensures the final product meets demanding automotive standards.

5. Custom Engineering Shops: Bespoke Piston Solutions

For projects demanding unique specifications, custom engineering shops offer bespoke piston solutions. These specialists cater to clients who need components that are not available off the shelf. They provide unparalleled precision and engineering for the highest levels of automotive performance.

The Ultimate in Customization

Custom shops provide the ultimate level of personalization. They use advanced CNC machining and design processes to create parts tailored to a specific application. This allows for unique features that optimize strength, weight, and efficiency. Some advanced custom designs include:

- FSR (Forged Side Relief): This design reduces the piston skirt width to minimize friction and power loss, a technique proven in demanding racing series like NASCAR.

- Ultra Crown Domes: This machining process creates extremely precise tolerances between the piston and cylinder head, optimizing compression for a more complete fuel burn.

- Gas Porting: Shops can add vertical or lateral gas ports. These small holes or slots use combustion pressure to improve ring seal, a critical feature for drag and circle track racing.

- 3D Under Crown Milling: This technique removes non-essential material from the piston’s underside, reducing weight and enhancing durability for high-RPM applications.

When to Choose a Custom Piston

A custom piston is the right choice when standard parts cannot meet the project’s goals. This is common in professional motorsports, vintage restorations, or experimental engine builds. Custom parts are expected to cost more than off-the-shelf options because the price includes specialized design time. However, this investment delivers a superior component. It often features stronger forgings, thinner ring packs, and lighter weights, providing a significant performance advantage.

Finding a Reputable Custom Shop

Choosing the right custom shop is critical for a successful outcome. A reputable shop demonstrates expertise through its manufacturing capabilities and quality control. Key criteria for evaluating a potential partner include:

- Material Expertise: The shop should work with high-strength materials like 2618 aluminum alloy for pistons and chrome moly for wrist pins.

- Customization Capability: They must be able to produce parts to exact specifications, including bore size, compression ratio, and pin diameter.

- Advanced Machining: Look for advanced CNC machining capabilities and proven quality systems, such as an ISO 9001 certification.

- Proven Track Record: A strong reputation in the racing or high-performance automotive community is a reliable indicator of quality and dependability.

Key Factors for Choosing Your Piston Source

Selecting the right supplier for automotive components requires careful consideration of several key factors. The material, intended application, and required production volume all play a critical role in finding a partner that can deliver the necessary quality and performance. A clear understanding of these elements helps shock absorber manufacturers make an informed decision that aligns with their product goals and market strategy.

Material and Manufacturing Process

The choice of material and manufacturing method directly impacts a piston’s durability, weight, and thermal properties. Steel offers high strength for heavy-duty automotive applications, while aluminum provides a lightweight alternative that improves efficiency. The right selection ensures long-term reliability and quality.

| Feature | Steel Pistons | Aluminum Pistons |

|---|---|---|

| Strength & Durability | Higher strength, ideal for high-compression engines | Lighter but wears faster under extreme pressure |

| Weight | Significantly heavier, affecting engine responsiveness | Significantly lighter, enhancing engine efficiency |

| Cost | Higher manufacturing and processing cost | More economical for mass production |

The manufacturing process further defines the product’s final performance. Forging produces a denser, stronger piston ideal for racing, while casting is a cost-effective solution for standard street vehicles. Advanced technologies like CNC machining deliver exact specifications and allow for complex custom designs, ensuring consistent quality for any high-performance automotive engine.

Application: Race, Off-Road, or Street

The intended application dictates the piston design. A part engineered for a daily driver prioritizes different characteristics than one built for a race car.

Comfort vs. Control 🏎️ Street-use shock absorbers often use linear rate pistons. These designs maintain a consistent softness to maximize comfort. In contrast, high-performance systems use digressive pistons that provide a compliant ride over small bumps but firm up for better vehicle stability during aggressive driving.

This focus on application-specific engineering ensures the final product delivers the right balance of performance and comfort. Choosing a source that understands these nuances is critical for success in the competitive automotive piston market.

Volume: OEM Scale vs. One-Off Customization

Production volume is a major factor that separates large-scale suppliers from custom shops. A large manufacturer working with major shock absorber manufacturers often has a minimum order quantity (MOQ). This can be around 500 pieces for a standard piston and may increase to 1,000 for a new development project. This scale allows for cost efficiency in mass production.

Conversely, a custom shop specializes in low-volume or one-off parts. While the cost per unit is higher due to design and setup time, it provides a component with unmatched performance and quality. For very small batches of 1-20 units, CNC machining or additive manufacturing is often more economical than paying for expensive forging dies, delivering superior durability and consistent performance for specialized automotive needs.

The Importance of Quality Certifications

Quality certifications are a crucial indicator of a manufacturer’s commitment to excellence. They serve as an independent verification of a company’s processes and its ability to deliver consistent quality. For shock absorber manufacturers, partnering with a certified supplier minimizes risk and ensures the final product meets high standards. The most respected certification in the automotive industry is IATF 16949. This standard is not just a badge; it is a framework for continuous improvement and superior quality management.

Choosing a supplier with IATF 16949 certification provides several key advantages. It demonstrates a deep commitment to quality that impacts every stage of production. This focus ensures reliable product performance.

Benefits of IATF 16949 Certification ✅

- Superior Product Quality: The certification demands strict adherence to standards, leading to enhanced product quality.

- Global Recognition: It is the worldwide benchmark for automotive quality, opening doors to international markets.

- Efficient Supply Chain: It improves collaboration with suppliers, which reduces defects and delays.

- Customer Trust: A certified supplier shows a dedication to reliable, high-quality parts, building long-term trust.

- Cost Savings: The standard helps optimize operations and reduce waste, leading to more sustainable production and better quality.

Ultimately, these certifications provide assurance. They confirm that a supplier has robust systems in place to control manufacturing processes and maintain a high level of quality. This disciplined approach results in components that deliver dependable performance. Sourcing from a certified piston factory is a fundamental step toward building a shock absorber known for its durability and exceptional performance. This commitment to quality protects brand reputation and ensures customer satisfaction.

Making the Final Choice 🎯 Selecting the right piston factory is critical for shock absorber manufacturers. The choice depends on performance, quality, and durability needs for all automotive components. A reliable manufacturer delivers high-quality products with proven reliability. For balanced performance and comfort, established automotive brands offer consistent performance. The right piston factory helps shock absorber manufacturers deliver a superior product with lasting quality, performance, and comfort. This choice defines the final piston product, its durability, and its success in the automotive piston market, making the piston factory selection critical for any automotive piston and manufacturer seeking top quality and reliability.

FAQ

Why is piston material important for performance?

Piston material directly affects performance and durability. A quality manufacturer uses specific automotive materials to manage heat and stress. This choice ensures the product delivers consistent damping force. It also guarantees long-term reliability for the entire suspension system.

What is the main difference between OEM and aftermarket pistons?

An OEM manufacturer builds parts to the vehicle’s original specifications, often balancing performance and comfort. Aftermarket suppliers may offer a different product focused on enhanced features. Shock absorber manufacturers choose a supplier based on their specific automotive goals.

How do certifications benefit shock absorber manufacturers?

Certifications like IATF 16949 show a manufacturer’s commitment to quality. This standard ensures process control and product reliability. Partnering with a certified automotive manufacturer gives shock absorber manufacturers confidence in the final component’s performance and consistency.

When should I choose a custom piston over a standard one?

Choose a custom piston for unique applications where standard parts fail to meet specific needs. Customization offers superior reliability for high-stress racing or restoration projects. It provides a perfect balance of comfort and control that a standard part cannot match.