A chrome cylinder rod is essential for extending the lifespan of hydraulic cylinders. Its durable, hard surface resists scratches and dents from everyday use, while the chrome layer offers excellent protection against rust and moisture. Many engineers rely on a chrome cylinder rod to minimize friction, resulting in less wear on seals. Equipment featuring these rods operates smoothly and requires fewer repairs over time.

What Is a Chrome Cylinder Rod?

Definition and Structure of Hydraulic Cylinder Rod

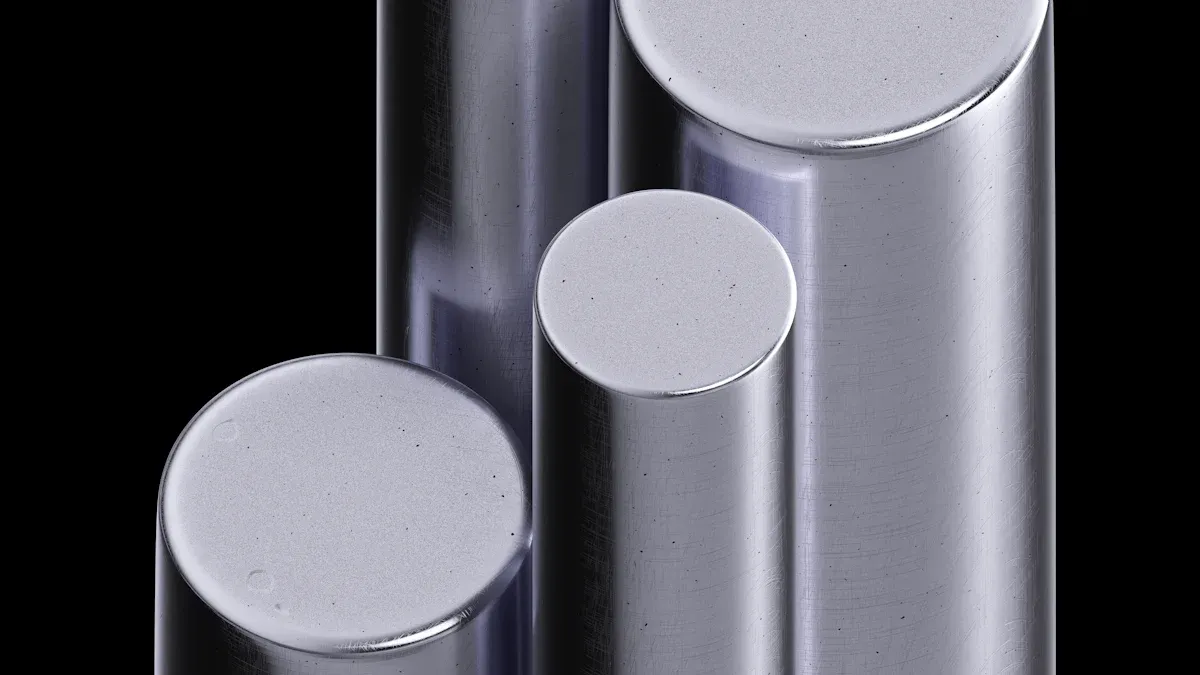

A hydraulic cylinder rod is a key part of hydraulic cylinders. It connects the piston inside the cylinder to the machine that needs to move. Most rods use hard chrome plated round rod as the main material. This rod starts as cold-rolled steel, which gives it strength. Manufacturers then grind and polish the rod to a smooth finish. After that, they add a layer of hard chrome. This chrome layer protects the rod from scratches, dents, and rust. The rod passes through a seal gland at the cylinder head. The seal gland holds several parts, such as primary and secondary seals, bearing elements, wipers, and static seals. These parts keep oil from leaking and block dirt from entering. The seals use materials like nitrile rubber, polyurethane, or metal, chosen for the job’s pressure and temperature. Wipers clean the rod as it moves, and bearing elements stop metal parts from rubbing together. Some rods also have threads or special ends for mounting.

Note: ScienceDirect and Wikipedia both explain that checking rod straightness is important. A bent rod can damage seals and cause leaks. Modern rods may use other coatings, but hard chrome remains the most common for its balance of hardness and corrosion resistance.

Role of Hard Chrome Plated Round Rod in Hydraulic Systems

The hard chrome plated round rod plays a vital role in hydraulic systems. Its hard surface resists wear, so the rod lasts longer even in tough jobs. The smooth, mirror-like finish reduces friction. This helps the piston move easily and keeps seals from wearing out too fast. The chrome layer also blocks moisture and chemicals, which stops rust and corrosion. In the Malaysian market, demand for these rods keeps rising. Sectors like construction and heavy engineering trust hard chrome plated round rod for their strength and reliability. Tests show that rods with hard chrome can last three to five times longer than uncoated rods, even after 200 hours in salt spray. Some advanced coatings, like NiKrom III, last even longer in harsh mining conditions and help companies save on maintenance.

| Property / Benefit | Description / Impact on Hydraulic Systems |

|---|---|

| High Surface Hardness | Reduces wear, extends rod and system life |

| Superior Corrosion Resistance | Protects against rust, even in wet or salty environments |

| Smooth Mirror-like Finish | Lowers friction, improves piston movement |

| Enhanced Load Bearing Capacity | Handles heavy loads, boosts reliability |

| Minimal Maintenance | Fewer repairs, less downtime |

| Hardness (Above 900 HV) | Withstands mechanical stress |

| Surface Roughness (Ra 0.2–0.4 μm) | Keeps friction and wear low |

| Straightness Tolerance (0.1 mm/m) | Maintains precision and alignment |

Hydraulic cylinder rod performance depends on these features. The hard chrome plated round rod ensures hydraulic cylinders work smoothly, last longer, and need less care. This makes them a smart choice for many industries.

Key Benefits of Chrome Cylinder Rods

Increased Durability and Hardness

A hard chrome plated round rod gives hydraulic cylinders a strong advantage in demanding environments. The chrome layer adds significant hardness to the rod’s surface. This extra hardness helps the rod resist dents, scratches, and other damage that can occur during heavy use. Recent studies compared rods coated with extreme high-speed laser metal deposition (EHLMD) to those made with conventional methods. The EHLMD process created a more uniform and dense crystal structure in the coating. This structure led to better mechanical properties, such as higher hardness and improved durability. Microstructural analysis and potentiodynamic polarization experiments confirmed that rods with EHLMD coatings last longer and perform better under stress. These findings show that a hard chrome plated round rod can handle tough jobs and extend the life of hydraulic cylinders.

Tip: Choosing rods with advanced coating technology can further boost the durability of your hydraulic equipment.

Superior Corrosion and Wear Resistance

Hydraulic cylinders often work in harsh conditions where moisture, chemicals, and dirt can cause rust and wear. A hard chrome plated round rod protects against these threats. Laboratory tests by Caterpillar revealed that traditional chrome rods failed after 350,000 cycles due to seal wear. In contrast, rods coated with Advanced Chrome Technologies (ACT) continued to work beyond one million cycles. This result shows a dramatic improvement in wear resistance. The ACT coating uses a high-density metal alloy with only about one percent porosity. This low porosity blocks water and chemicals from reaching the steel underneath, which prevents corrosion and oxidation. The high-velocity thermal coating method also makes the rod surface tougher against scratches and environmental abuse. These features help the hard chrome plated round rod maintain its performance and extend the service life of hydraulic cylinders.

- Key points:

- ACT-coated rods last over three times longer than traditional chrome rods.

- High-density alloy and low porosity provide excellent corrosion resistance.

- The coating stands up to harsh environments and heavy use.

Reduced Friction and Seal Protection

A chrome cylinder rod with a smooth, hard chrome finish reduces friction as it moves through the seals. Lower friction means less heat and less wear on both the rod and the seals. An experimental study on hard chromium coated 1010 mild steel measured the coefficient of friction as the rod slid over time. The results showed a clear drop in friction rates as the sliding distance increased. The hard chrome coating also increased the rod’s hardness and reduced weight loss compared to uncoated steel. Even though some microcracks appeared in the coating, they did not affect the friction benefits. Lower friction helps the seals last longer and keeps hydraulic cylinders running smoothly. This benefit reduces the need for frequent repairs and helps prevent oil leaks.

Note: Reduced friction not only protects seals but also improves the efficiency of the entire hydraulic system.

Lower Maintenance and Downtime

Hydraulic systems often face tough working conditions. Dust, moisture, and heavy loads can cause parts to wear out quickly. When a hydraulic cylinder fails, machines stop working. This leads to lost time and higher repair costs. Using a chrome cylinder rod helps solve these problems.

Field experience and industry reports show clear results. The KOMATSU Report 2014 and A.W. Chesterton’s application data reveal that hard chrome plating on cylinder rods can double the service life of hydraulic cylinders. Some mining machines have reached over 15,000 hours of operation before needing major repairs. This longer service life means fewer breakdowns and less time spent on maintenance.

Machines with chrome-plated rods spend more time working and less time in the repair shop. This boosts productivity and helps companies manage their equipment better.

Many companies in mining and construction have noticed these benefits. They report fewer emergency repairs and lower costs for spare parts. Workers spend less time fixing machines and more time getting the job done. The smooth, hard surface of the rod also protects seals and keeps dirt out. This reduces the risk of oil leaks and keeps the hydraulic system running smoothly.

A few key points highlight why maintenance and downtime drop with chrome-plated rods:

- Longer service life means fewer replacements.

- Less wear on seals and other parts.

- Fewer oil leaks and cleaner operation.

- Lower risk of sudden breakdowns.

These improvements help companies save money and keep projects on schedule. Choosing the right rod can make a big difference in how often machines need repairs.

How Hard Chrome Plating Works

The Chrome Plating Process for Hydraulic Cylinder Rods

Hard chrome plating gives hydraulic cylinder rods their strength and long-lasting surface. The process starts with a careful inspection of the rod. Engineers check for any signs of corrosion, pitting, or cracks. If the rod has old chrome, technicians remove it by grinding or by using a special electric process called electrolytic stripping. This step makes sure the steel underneath stays smooth and undamaged.

Next, workers clean the rod to remove any dirt or oil. They mask the ends to protect areas that should not get plated. The rod then goes into a warm chromic acid bath. Here, the rod connects to a power supply. Electricity flows through the bath, causing chromium particles to stick to the rod’s surface. This forms a hard, shiny layer. After plating, the rod is rinsed, then ground and polished. This step gives the rod a smooth finish and the right thickness. Engineers inspect the rod again to check for any flaws. Finally, they wrap the rod in protective material for safe transport.

Tip: Microcracks in the hard chrome plating help hold lubricant, which protects seals and reduces wear.

Importance of Plating Quality and Precision

Quality and precision matter at every stage of hard chrome plating. Engineers use strict standards to make sure each rod meets exact requirements. They measure the rod’s diameter, chrome layer thickness, and surface roughness. For example, the chrome layer must be at least 15 micrometers thick for rods under 20 mm in diameter, and at least 20 micrometers for larger rods. Surface roughness should not go above Ra 0.2 micrometers. The rod’s hardness must reach at least 800 HV. Straightness is also checked, with tight limits to keep the rod working smoothly in the cylinder.

| Quality Metric | Specification |

|---|---|

| Diameter Tolerance | ISO f7~f8 |

| Chrome Layer Thickness | ≥15 μm (<20 mm); ≥20 μm (≥20 mm) |

| Surface Roughness | Max Ra 0.2 μm |

| Surface Hardness | Min 800 HV |

| Straightness | 0.3 mm/1000 mm (≤16 mm); 0.2 mm/1000 mm (>16 mm) |

Engineers also test for defects like peeling, pitting, or black spots. They use special machines to check thickness and hardness. Salt spray tests show how well the hard chrome plating resists corrosion. These steps ensure that each hydraulic cylinder rod will last longer and perform well in tough conditions.

Note: High-quality hard chrome plating not only protects the rod but also helps the whole hydraulic system work better and last longer.

Recognizing Wear and Maintenance Needs

Common Signs of Chrome Cylinder Rod Wear

Regular inspection helps keep hydraulic equipment running smoothly. Maintenance logs and technical documents highlight several signs that show wear on a chrome cylinder rod. Corrosion often appears first when the chrome finish wears off. Pitting, scuff marks, and uneven wear can develop, especially if the rod is misaligned. Misalignment causes one side of the rod to wear faster than the other. Shiny areas next to dull spots may signal that the rod has bent. Damage types such as scoring, dents, or wear that reaches the base metal also indicate problems.

Technicians often use a checklist to spot these issues:

- Inspect for corrosion, pitting, and surface wear.

- Look for uneven wear, which may point to misalignment.

- Check for shiny versus dull surfaces to detect bending.

- Note minor scratches, which can sometimes be polished out.

- Address the root cause of any damage before reinstalling a repaired rod.

Regular visual checks help catch these problems early. Maintenance teams also record these signs to plan repairs and prevent bigger failures. Seal damage, fluid leaks, and the effects of dirt or high temperatures can speed up wear on the hydraulic cylinder rod.

When to Replace or Rechrome a Hydraulic Cylinder Rod

Knowing when to replace or rechrome a rod keeps hydraulic systems reliable. Several warning signs suggest that action is needed. Leaks from cylinder caps, seals, or fittings often mean the rod surface has worn down. Slow or jerky piston movement can signal deeper scoring or damage. Excessive wear, visible pitting, or scoring on the rod surface reduces the life of seals and can lead to system failure. Contaminated hydraulic fluid and loss of pressure also point to rod problems.

If the rod shows surface damage like pitting or scoring that cannot be polished out, rechroming restores the hard chrome plating and extends service life. Rechroming works best when the steel underneath remains solid. If wear reaches the base metal or the rod is bent or cracked, replacement is the safest choice. Defects from previous plating, such as blistering or cracking, also require attention. By following these guidelines, maintenance teams ensure the hydraulic cylinder rod continues to perform well and protect the entire system.

Practical Tips for Maximizing Hydraulic Cylinder Life

Choosing the Right Hard Chrome Plated Round Rod

Selecting the best hard chrome plated round rod is important for hydraulic cylinder performance. Engineers look at several key specifications to make the right choice. The material often used is 1045 chrome plated steel bar, which provides strong yield strength—at least 75,000 PSI, and up to 100,000 PSI for induction-hardened rods. The chrome plating thickness should be at least 0.0005 inches per side, with some rods offering up to 0.001 inches for extra protection. Surface finish matters, too. A smooth finish, usually between 6 and 12 Ra, helps reduce friction and wear.

| Specification/Property | Details/Values |

|---|---|

| Material | 1045 Chrome Plated Steel Bar |

| Yield Strength | 75,000–100,000 PSI |

| Chrome Plating Thickness | 0.0005″–0.001″ per side |

| Corrosion Resistance | 500–1000 hours salt spray (ASTM B117) |

| Hardness (Chrome Plate) | 66–72 RC |

| Surface Finish | 6–12 Ra |

| Diameter Range | 3/4″–5″ |

| Lengths Available | 16–24 feet |

Industry experts recommend focusing on total value, not just initial cost. High-quality steel, precise machining, and consistent chrome plating all help extend cylinder life. Testing for salt spray resistance, using certified labs, ensures the rod will last in tough environments. These steps help reduce downtime and lower warranty costs.

Maintenance Best Practices for Chrome Cylinder Rods

Proper maintenance keeps hydraulic cylinders working longer. Technicians follow several best practices to protect the hard chrome plated round rod and other parts:

- Clean the rod and seals regularly to remove dirt and prevent scratches.

- Use seals that match the hydraulic fluid type to reduce friction and wear.

- Inspect seals and consider adding gland drains to spot early signs of wear.

- Choose cylinder components made from materials that handle extreme temperatures and environments.

- Protect rods with boots, but check them often for tears that could let in contaminants.

- Keep hydraulic fluid clean to avoid damage to seals and cylinder surfaces.

Regular inspection after chrome plating checks thickness and surface roughness. This step ensures quality and prevents early failures.

Technicians also use advanced repair methods like honing, polishing, and seal replacement. Accelerated Life Testing, such as salt spray fog chamber tests, helps verify the rod’s corrosion resistance. Data from these tests guide maintenance schedules and predict when repairs are needed. Using rods regularly, rather than letting them sit idle, also helps prevent corrosion. Combining traditional care with modern data analysis allows teams to catch problems early and keep hydraulic systems running smoothly.

Chrome cylinder rods help hydraulic cylinders last longer and work better. Their hard, smooth surfaces protect against wear and rust. Scientific studies show that the right rod surface can make seals last longer and keep systems running smoothly. Companies that choose high-quality rods, like those from Max, see less downtime and lower repair costs.

- Key benefits include:

- Greater durability

- Better seal protection

- Improved cost-effectiveness

Regular checks and good care help these rods deliver the best results.

FAQ

What makes hard chrome plating important for hydraulic cylinder rods?

Hard chrome plating increases surface hardness and resists corrosion. Laboratory tests show chrome-plated rods last up to three times longer than uncoated rods. This protection helps hydraulic cylinders work better in harsh environments.

How often should technicians inspect chrome cylinder rods?

Technicians should inspect rods during every scheduled maintenance. Regular checks help spot early signs of wear, such as pitting or scratches. Early detection prevents bigger problems and keeps hydraulic systems running smoothly.

Can a damaged chrome cylinder rod be repaired?

Technicians can repair minor scratches or surface wear by polishing. If deeper damage or pitting appears, rechroming restores the protective layer. Replacement becomes necessary when the rod bends, cracks, or wears down to the base metal.

Why do high-quality rods reduce maintenance costs?

High-quality rods resist wear and corrosion. This durability means fewer breakdowns and less frequent repairs. Companies save money on spare parts and labor. Studies show machines with chrome-plated rods spend more time working and less time in the repair shop.