Durability is a key factor in the reliability of industrial and mechanical components, ensuring systems operate efficiently under challenging conditions. Among these essential components, the chrome piston rod shines for its outstanding performance. Featuring a hard chrome coating, the chrome piston rod is highly resistant to wear and tear, making it perfect for high-stress environments. For example, its surface roughness significantly improves, reducing from 0.16 to 0.10 μm, which enhances operational smoothness. Furthermore, the wear rate of a hard chrome-coated rod is approximately 38%, showcasing its ability to endure demanding usage. With its durable design and material efficiency, the chrome piston rod continues to set new standards in industrial applications.

Understanding Chrome Piston Rods

What Are Chrome Piston Rods?

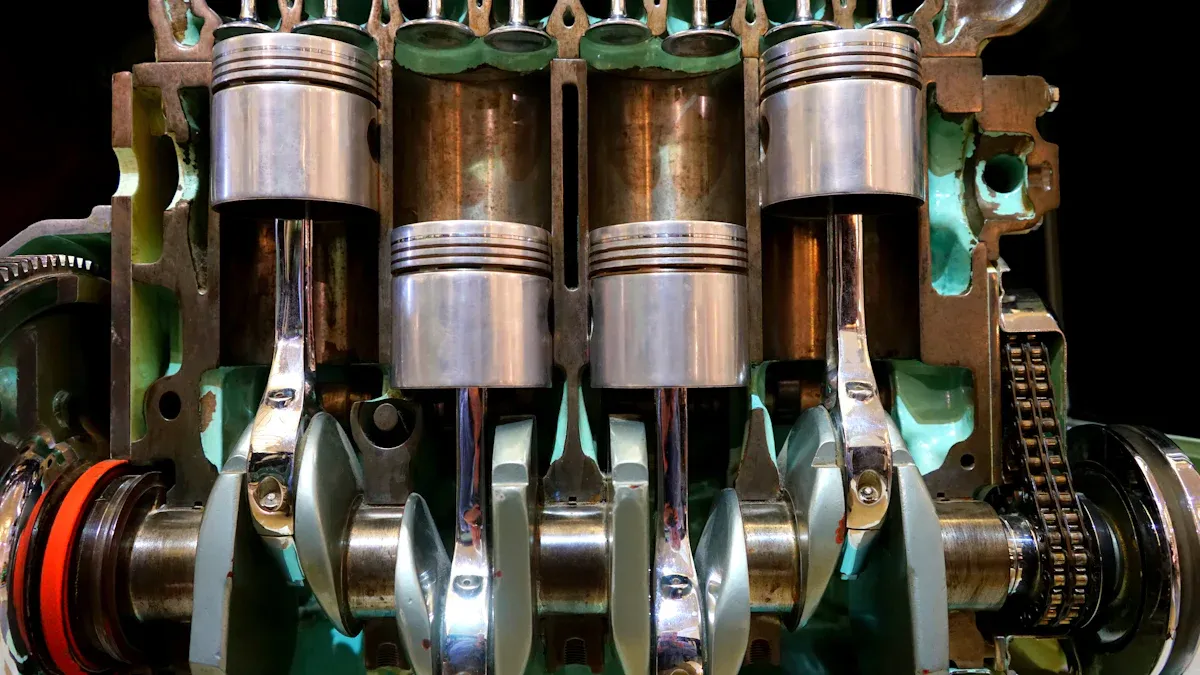

Chrome piston rods are essential components in hydraulic systems, industrial machinery, and other mechanical setups. These rods consist of a central shaft coated with hard chrome plating, which enhances their durability and performance. The design includes several critical components, each serving a specific purpose.

| Component | Description |

|---|---|

| Crown | Made of heat-resisting steel with five ring grooves, hard-chrome plated on both lands. |

| Skirt | Constructed from cast iron. |

| Piston Rod | Made of forged steel, fixed to the crosshead with a hydraulic tightened stud. |

| Central Bore | Connects with a cooling oil pipe and insert for oil inlet and outlet. |

| Material Options | Medium carbon steel (ground and polished or chromium plated) or ground and polished stainless steel. |

| Diameter Considerations | Chosen based on end loading and length to prevent buckling. |

| Bearing Materials | Usually sintered bronze or plastic sleeves in end covers. |

| Sealing Mechanisms | Simple elastomer seals for light duty; multiple seals for medium/heavy duty cylinders. |

| Protection for Rods | Gaiters or bellows may be used for protection in dirty or wet conditions. |

This table highlights the intricate design and material choices that make chrome piston rods reliable for industrial applications.

Hard Chrome Plating and Its Benefits

Hard chrome plating is the key feature that sets these rods apart. It creates a protective layer on the surface, offering several benefits:

- Enhanced Corrosion Resistance: The plating shields the rod from moisture, chemicals, and pollutants, ensuring long-term integrity.

- Improved Hardness and Wear Resistance: The hard chrome layer withstands mechanical stress and abrasion, making the rod ideal for high-stress environments.

- Easy to Clean and Maintain: The smooth surface resists dirt and contaminants, simplifying maintenance tasks.

- Electrical Conductivity: Hard chrome plating facilitates electrical current flow, which is crucial in aerospace and other specialized applications.

By incorporating hard chrome plating, you gain a component that excels in durability and performance, even in challenging conditions.

Material Choices and Their Impact on Performance

The materials used for chrome piston rods significantly influence their durability and functionality. High-strength steel is often preferred for its ability to handle heavy loads and resist deformation. Stainless steel options are ideal for corrosive environments, offering enhanced durability.

| Aspect | Evidence |

|---|---|

| Material Strength | Fatigue strength increases with the tensile strength of the rod material. |

| Cost Reduction Potential | Using stronger materials can reduce costs by 20 to 30% compared to commonly used materials. |

| Impact of Surface Treatment | Chrome plating can lead to porosity due to slag inclusions, affecting the durability of the rods. |

| Importance of Diameter | Reducing the diameter of the rod can decrease costs by 15% but requires strong materials to maintain performance. |

Induction hardening is another critical process for piston rods. It strengthens the outer surface while keeping the core tough, allowing the rods to endure heavy loads and continuous motion. This treatment is essential for hydraulic cylinders, extending their lifespan and ensuring reliable performance.

Durability and Hardness of Chrome Plated Rods

Surface Hardness and Wear Resistance

The surface hardness of chrome plated rods plays a critical role in their performance. Hard chrome plating creates a robust outer layer that resists deformation and wear. This makes the rods suitable for high-stress applications. The Vickers hardness test (ASTM E384) reveals that chrome plated rods typically achieve a surface hardness between 900 and 1100 HV. This level of hardness ensures that the rods can endure repeated mechanical stress without compromising their structural integrity.

Wear resistance is another key advantage of hard chrome plating. Compared to uncoated steel, chrome plated rods demonstrate wear resistance that is 10 to 20 times better. This remarkable improvement results from the microstructure of the coating and its smooth surface finish. The pin-on-disk test (ASTM G99) confirms these findings, highlighting the superior durability of chrome plated rods in abrasive environments.

| Performance Parameter | Typical Value Range | Test Method | Key Influencing Factors |

|---|---|---|---|

| Surface Hardness | 900-1100 HV | Vickers hardness test (ASTM E384) | Coating thickness, process parameters |

| Wear Resistance | 10-20 times better than uncoated steel | Pin-on-disk test (ASTM G99) | Coating microstructure, roughness |

By choosing chrome plated rods, you gain components that excel in both hardness and wear resistance, ensuring reliable performance in demanding conditions.

Corrosion Resistance in Challenging Environments

Corrosion resistance is essential for components exposed to harsh environments. Hard chrome plating provides a protective barrier that shields the underlying material from moisture, chemicals, and pollutants. This protection ensures that chrome plated rods maintain their structural integrity over time.

Empirical data highlights the effectiveness of chrome plating in resisting corrosion. For example:

- The EHLMD coating demonstrates superior corrosion resistance with a polarization resistance of 709.79 kΩ·cm².

- The CLMD coating achieves a polarization resistance of 356.69 kΩ·cm².

- These results were obtained through testing in a 0.598 mol/L NaCl solution at room temperature.

These findings confirm that chrome plated rods can withstand extreme conditions, making them ideal for industries such as marine, offshore, and chemical processing. However, proper application of the plating is crucial. Improper techniques can lead to issues like pitting and spalling, which compromise the rods’ corrosion resistance. Multiple layers of plating may be required in some cases to achieve optimal performance.

Lifespan and Maintenance Considerations

Hard chrome plating significantly extends the lifespan of components, including piston rods. The plating enhances the wear life of the base material by 2 to 10 times, depending on factors such as surface preparation, plating solution quality, and coating thickness. In many cases, chrome plated rods can last for decades, even in harsh operating conditions.

A study concluded that variations in hardness among chrome plated specimens significantly affect their fretting fatigue life. This indicates that chrome plating not only improves durability but also enhances resistance to crack initiation and propagation.

Maintenance is another critical factor in ensuring the longevity of chrome plated rods. The smooth surface of the plating resists dirt and contaminants, simplifying cleaning and reducing the need for frequent maintenance. Regular inspections and proper handling further contribute to the rods’ extended service life.

By investing in high-quality chrome plated rods, you benefit from components that offer exceptional durability, reduced maintenance requirements, and a longer operational life.

Applications of Hard Chrome Piston Rods

Hydraulic Systems and Industrial Machinery

Hydraulic systems and industrial machinery rely heavily on components that can endure high pressure and repetitive motion. Chrome piston rods, with their hard chrome plating, excel in these demanding environments. The plating enhances surface hardness, wear resistance, and corrosion protection, ensuring reliable performance even under extreme conditions.

In hydraulic systems, chrome plated rods operate seamlessly at pressures up to 300 bar. Their smooth surface finish, often below Ra 0.2 µm, minimizes friction and prevents wear. This feature is crucial for industrial automation, where components must withstand millions of operational cycles without failure. For example, in energy sector applications, these rods deliver a service life exceeding 15 years, even in saline environments. Their ability to handle pressures up to 20,000 psi in subsea applications further highlights their durability.

| Application Area | Key Performance Metrics | Durability Specifications |

|---|---|---|

| Automotive | Operate at pressures up to 300 bar | Lightweight materials for fuel efficiency |

| Aerospace and Defense | Withstand temperatures from -65°C to 300°C | Materials rated for pressures exceeding 500 bar |

| Industrial Automation | Cycle lifetimes exceeding 10 million operations | Surface roughness below Ra 0.2 µm to prevent wear |

| Energy Sector | Service life beyond 15 years in saline environments | Rated for 20,000 psi pressures in subsea applications |

By choosing chrome plated rods for hydraulics and industrial machinery, you ensure long-lasting performance, reduced maintenance, and cost efficiency.

Automotive and Heavy-Duty Equipment

In the automotive and heavy-duty equipment sectors, durability and reliability are non-negotiable. Chrome piston rods, with their hard chrome plating, meet these requirements by offering exceptional wear resistance and longevity. These rods are designed to handle the high pressures and abrasive conditions typical of heavy-duty applications.

Comparative studies have shown that tungsten carbide-coated rods outperform hard chrome plating in terms of wear resistance. However, chrome plated rods remain a cost-effective choice for many applications. For instance, in hydraulic cylinders used in construction equipment, hard chrome plating provides sufficient fatigue strength to operate efficiently under high pressure. This reduces the frequency of component replacement and minimizes downtime.

In the automotive industry, chrome plated rods contribute to fuel efficiency by utilizing lightweight materials. They also enhance the performance of shock absorbers and other critical components, ensuring a smoother ride and longer service life. By investing in these rods, you gain a reliable solution that balances performance and cost.

Marine and Offshore Uses

Marine and offshore environments present unique challenges, including exposure to moisture, salt, and corrosive chemicals. Chrome piston rods, with their hard chrome plating, are specifically engineered to withstand these harsh conditions. The plating provides a protective barrier that meets ISO 9227 NSS standards, ensuring superior corrosion resistance.

| Feature | Description |

|---|---|

| Corrosion Resistance | Meets ISO 9227 NSS standards, providing superior protection against rust and oxidation. |

| Durability | Designed for maximum efficiency and extended lifespan in harsh environments. |

| Environmental Resistance | Specifically engineered to withstand moisture, high temperatures, and corrosive chemicals. |

These rods also feature enhanced surface finishing to combat salt damage and abrasion. A self-healing coating technology further improves their corrosion resistance, ensuring long-term performance. This makes them ideal for marine, chemical, and heavy industrial settings.

By using chrome plated rods in marine and offshore applications, you benefit from components that maintain their integrity and efficiency, even in the most demanding environments.

Aerospace and Defense Applications

Aerospace and defense industries demand components that can endure extreme conditions while maintaining precision and reliability. Chrome plated rods play a vital role in these applications, offering unmatched durability and performance. You will find these rods in critical systems such as landing gear, hydraulic actuators, and missile guidance systems.

The hard chrome plating on these rods provides exceptional abrasion and rust resistance, ensuring they perform flawlessly in harsh environments. For example, aerospace components often face rapid temperature changes, high altitudes, and exposure to corrosive elements. Chrome plated rods excel in these conditions due to their hard surface and superior corrosion resistance. This makes them an ideal choice for applications where failure is not an option.

In defense systems, chrome plated rods contribute to the reliability of heavy-duty machinery and precision equipment. Hydraulic systems in military vehicles rely on these rods to operate under high pressure and continuous motion. Their hard surface resists wear, even in high-volume industrial automation processes used to manufacture defense equipment. This ensures consistent performance over extended periods.

You might wonder how these rods handle the unique challenges of aerospace applications. The answer lies in their ability to maintain structural integrity under stress. Hard chrome plating enhances the rods’ surface hardness, allowing them to withstand the intense forces experienced during takeoff, landing, and flight. Additionally, the plating minimizes problems like pitting and spalling, which can compromise the rods’ performance.

Another advantage of chrome plated rods is their lightweight design. In aerospace applications, reducing weight is crucial for improving fuel efficiency and overall performance. These rods achieve this balance by combining a strong core material with a thin yet durable chrome layer. This design reduces the risk of deformation while keeping the component light.

Maintenance is another area where chrome plated rods shine. Their smooth surface resists dirt and contaminants, making cleaning easier. This reduces downtime and ensures that aerospace and defense systems remain operational for longer periods. By choosing chrome plated rods, you gain components that deliver reliability, durability, and cost-effectiveness in critical applications.

Tip: Always ensure proper inspection and maintenance of chrome plated rods to maximize their lifespan and performance in aerospace and defense systems.

Comparing Hard Chrome Plated Rods to Alternatives

Hard Chrome vs. Stainless Steel Rods

When comparing hard chrome plated rods to stainless steel rods, you’ll notice distinct differences in performance and application. Hard chrome plated rods excel in wear resistance and surface hardness. The chrome plating process creates a robust outer layer that withstands abrasion and mechanical stress. Stainless steel rods, on the other hand, offer superior corrosion resistance, especially in environments with high humidity or exposure to chemicals.

However, stainless steel rods lack the surface hardness provided by chrome plating. This makes them less suitable for applications requiring high durability under heavy loads. Over time, stainless steel may deform or wear faster than hard chrome plated rods. If your application involves high-stress environments, hard chrome plated rods provide a more reliable solution.

Hard Chrome vs. Induction-Hardened Chrome Bars

Induction-hardened chrome bars offer a higher hardness level compared to hard chrome plated rods. These bars achieve a hardness of RC 55-60, while hard chrome plated rods typically range from RC 45-50. This makes induction-hardened bars ideal for heavy-duty applications where extreme durability is required.

| Property | Hard Chrome Plated Rods | Induction-Hardened Chrome Bars |

|---|---|---|

| Hardness | RC 45-50 | RC 55-60 |

| Durability | Moderate | High |

| Versatility | Limited to specific uses | Suitable for heavy-duty use |

| Cost | Lower | Higher |

Despite their advantages, induction-hardened chrome bars come with a higher cost. The chrome plating process used on hard chrome rods offers a more economical option while still delivering excellent performance for most industrial applications. If cost is a concern, hard chrome plated rods strike a better balance between affordability and functionality.

Cost-Effectiveness and Performance Analysis

The cost-effectiveness of hard chrome plated rods lies in their ability to deliver high performance at a lower price point. The chrome plating process enhances the rods’ surface properties, making them resistant to wear and corrosion. While alternative coatings like HVOF or ceramic coatings may offer unique benefits, they often lead to increased seal wear and premature failure after extended use.

- Hard chrome surfaces become smoother over time, reducing friction against seals.

- Alternative coatings may initially perform well but can cause leakage and wear issues after prolonged testing cycles.

- Micro-cracks on hard chrome surfaces may form, but they rarely compromise the overall durability of the rod.

By choosing hard chrome plated rods, you gain a cost-effective solution that balances durability, performance, and affordability. These rods remain a reliable choice for industries requiring components that endure heavy use without frequent replacement.

Hard chrome piston rods deliver unmatched durability and performance, making them indispensable across industries. Their versatility shines in applications ranging from hydraulic systems to aerospace. You benefit from components that resist corrosion, minimize wear, and handle heavy loads with ease.

- Chrome rods resist rust and chemical corrosion, extending the life of hydraulic cylinders.

- The hard surface reduces wear, ensuring longer-lasting seals and fewer repairs.

- A smooth finish prevents seal damage, reducing downtime.

- Chrome rods handle higher loads without bending, ensuring safer operations.

- These combined benefits lead to a longer lifespan and lower maintenance costs.

By choosing hard chrome piston rods, you gain a cost-effective solution that ensures reliability and efficiency in demanding environments.

FAQ

What makes hard chrome piston rods more durable than alternatives?

Hard chrome piston rods feature a robust chrome layer that resists wear, corrosion, and mechanical stress. This coating enhances surface hardness and reduces friction, ensuring long-lasting performance in demanding environments. Compared to alternatives, they offer superior durability at a cost-effective price.

How do you maintain hard chrome piston rods for optimal performance?

Regularly inspect the rods for signs of wear or damage. Clean them with a soft cloth to remove dirt and contaminants. Avoid using abrasive materials that could scratch the chrome surface. Proper maintenance extends their lifespan and ensures reliable operation.

Are hard chrome piston rods suitable for marine environments?

Yes, hard chrome piston rods excel in marine environments. The chrome plating provides excellent corrosion resistance, protecting the rods from moisture, salt, and chemicals. This makes them ideal for offshore applications where durability and reliability are critical.

Can hard chrome piston rods handle high-pressure applications?

Absolutely! Hard chrome piston rods are designed to withstand high-pressure environments. Their enhanced surface hardness and wear resistance make them suitable for hydraulic systems and industrial machinery operating under extreme stress.

What industries benefit the most from hard chrome piston rods?

Industries like automotive, aerospace, marine, and heavy machinery benefit greatly. These rods improve performance in hydraulic systems, shock absorbers, and industrial equipment. Their durability and versatility make them indispensable across various applications.