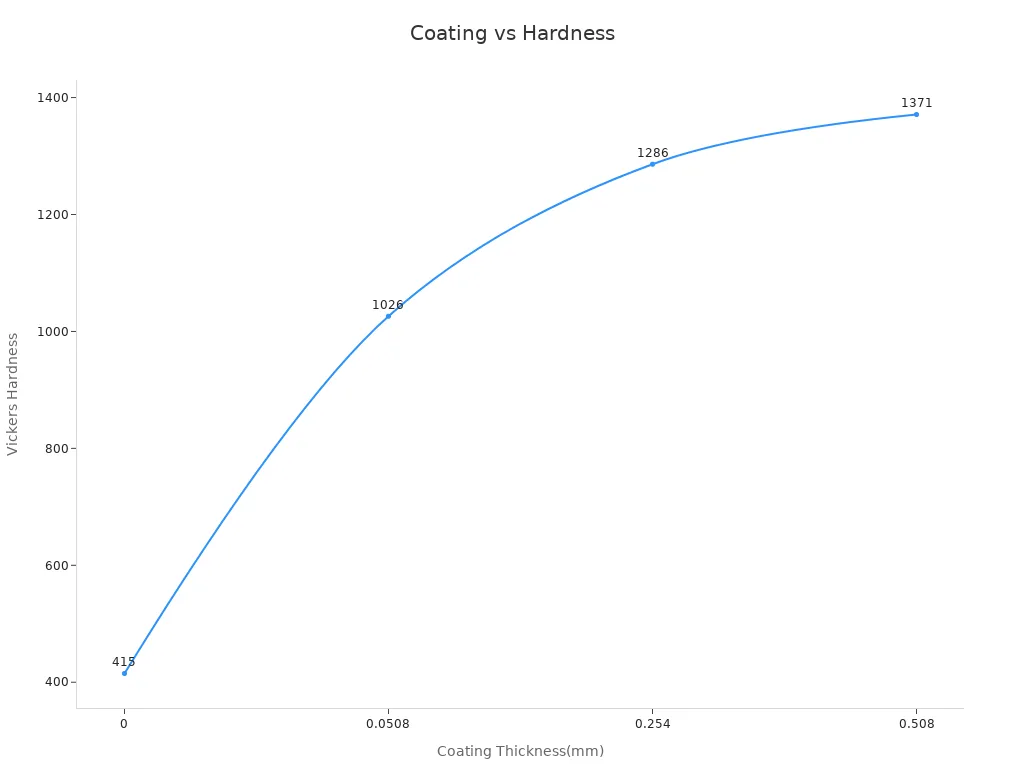

When you choose a chrome plated steel rod, you unlock significant advantages for demanding environments. Chrome plated steel rods are known for their high surface hardness, exceptional corrosion resistance, and smooth finish, making them a superior choice. For instance, the Vickers hardness number for a chrome plated steel rod increases from 415 HV for uncoated steel to 1371 HV with a 0.508 mm chrome layer, as detailed below:

| Coating Thickness (mm) | Vickers Hardness Number (HV) | Corrosion & Wear Resistance |

|---|---|---|

| 0 (uncoated steel) | 415 | Baseline |

| 0.0508 | 1026 | Significantly improved |

| 0.254 | 1286 | Significantly improved |

| 0.508 | 1371 | Significantly improved |

Thanks to these outstanding properties, a chrome plated steel rod can deliver up to five times longer wear life and up to 1500 hours of salt spray protection. These benefits make chrome plated steel rods the preferred solution in hydraulic systems, industrial machinery, and heavy equipment, where maximum performance and extended service life are essential.

What Are Chrome Plated Steel Rods?

Definition and Composition of Chrome Plated Steel Rods

You will find chrome plated steel rods in many industries because they combine a strong steel core with a hard, protective chrome layer. The base steel often uses medium carbon grades like SAE 1045, S45C, or 42CrMo4. These steels have a carbon content between 0.36% and 0.50%, which gives them good strength and toughness. The chrome plating process adds a thin layer of chromium, usually between 0.0005 and 0.002 inches thick. This layer increases surface hardness to about 65-72 HRC and provides excellent wear and corrosion resistance.

Chrome plated steel rods stand out in demanding applications such as hydraulic cylinders, industrial machinery, and automotive parts. The combination of a tough steel core and a hard chrome surface makes them ideal for environments where durability and reliability matter most.

Here is a table showing the typical composition and properties of chrome plated steel rods:

| Property | Value/Range |

|---|---|

| Base Steel Grades | SAE 1045, S45C, 42CrMo4 |

| Carbon Content | 0.36% – 0.50% |

| Chrome Layer Hardness | 65-72 HRC (940-1210 HV) |

| Plating Thickness | 0.0005 – 0.002 inches |

| Tensile Strength | 610 – 900 MPa |

| Yield Strength | 355 – 800 MPa |

| Elongation | 15% – 20% |

The chrome plating process ensures that these rods meet the high standards required for critical chrome plating applications.

Chrome Plating and Manufacturing Process Overview

You can understand the value of chrome plated steel rods by looking at the chrome plating process. This process involves several careful steps to create a durable and smooth finish. Here is how the chrome plating process works:

- Surface preparation removes oils and dirt using chemical cleaners.

- The rod goes into an acid bath to activate the surface for better chrome bonding.

- A nickel base layer is applied to improve corrosion resistance before chrome plating.

- The rod enters a chrome plating bath, where an electric current deposits the chrome layer.

- Rinsing and drying remove chemicals, and polishing creates a smooth finish.

- Inspection checks for defects like cracks or uneven plating thickness.

The chrome plating process uses equipment such as degreasing tanks, acid baths, plating baths, rectifiers, and polishing machines. Each step in the chrome plating process is important for quality and performance. The process uses chemicals like chromic acid and hydrochloric acid, and it controls factors such as bath temperature and current density.

You see the results of this careful chrome plating process in the growing demand for chrome plated steel rods. The U.S. market for internal chrome plated steel tubes reached $1.5 billion in 2024 and is expected to grow to $2.5 billion by 2033. Hydraulic equipment sales have grown at over 6.5% per year, and more than 72% of large manufacturers now use automated production lines. In Europe, the chrome plating market is projected to reach $5.31 billion by 2035, driven by automotive, aerospace, and metal finishing applications.

| Aspect | Data / Insight |

|---|---|

| U.S. Internal Chrome Plated Steel Tube Market Value (2024) | USD 1.5 billion |

| Forecast CAGR (2026-2033) | 5.5% |

| Market Value Projection (2033) | USD 2.5 billion |

| Hydraulic Equipment Sales Growth (2020-2024 CAGR) | Over 6.5% |

| Industrial Automation Adoption | Over 72% of large manufacturers use automated production lines |

| Projected Annual Demand Growth for Corrosion-Resistant Tubing | 7.2% |

| Europe Chrome Plating Market Size (2024) | USD 3.38 billion |

| Market Size Projection (2035) | USD 5.31 billion |

| Key Growth Drivers | Automotive, aerospace, metal finishing |

The chrome plating process gives you rods that last longer and perform better in tough applications. This is why you see chrome plated steel rods used in so many industries today.

Key Properties of Chrome Plated Steel Rods

Hardness and Strength in Hardened Chrome Rods

When you select hardened chrome rods, you choose a product built for high strength and reliability. These rods use a steel core, often made from high strength steel, and receive a hard chrome plating that transforms their surface. The chrome plated surface reaches a hardness between 800 and 1000 HV, which means you get excellent wear resistance and long-lasting durability. Laboratory tests, such as the Rockwell Hardness Test, confirm that hardened chrome rods achieve surface hardness values from 50 to 60 HRC. This level of hardness ensures that your rods can handle heavy loads and repeated impacts without deforming.

You benefit from consistent strength because the hard chrome plating process increases surface hardness to 65–69 HRC and reduces surface roughness to as low as Ra 0.1–0.5 μm. This smooth finish helps the rods resist friction and wear. The table below shows key quality metrics for hardened chrome rods:

| Quality Metric | Empirical Evidence Description |

|---|---|

| Chromium Coating Thickness | 8–250 microns, often with a nickel undercoat for added toughness |

| Surface Hardness | 800–1000 HV, ideal for wear resistance |

| Surface Roughness (Ra) | ≤0.2 microns, ensures smooth operation |

| Thermal Shock Resistance | No cracks after 300°C heating and water cooling |

| Compliance and Standards | Meets ISO 9001:2015, TS16949, AMS2460, ASTM B650 |

You can trust hardened chrome rods to deliver high strength and durability in demanding environments. The induction hardened chrome plated rod offers even greater strength by combining a hardened core with a tough chrome plated surface. This combination gives you rods that last longer and perform better under stress.

Corrosion Resistance from Chrome Plating

Corrosion resistance is one of the most important properties you need in industrial applications. Hardened chrome rods provide outstanding protection against corrosion because of their dense, low-porosity chrome plating. The plating process creates a barrier that blocks moisture, chemicals, and other corrosive agents from reaching the steel core. You can see this in salt spray tests, where rods with hard chrome plating achieve ISO 4540 ratings between 7 and 10. These results show strong corrosion protection.

The table below highlights the corrosion resistance performance of chrome plated rods:

| Feature | Chrome Plating Performance |

|---|---|

| Porosity Level | ≤3 micropores/cm² (better than AMS 2460 standard) |

| Corrosion Resistance | NiKrom III cylinders last up to 5 times longer corrosion-free than standard hexavalent chrome coatings in harsh environments |

| Environmental Applications | Mining, marine, construction, hydraulic systems, industrial machinery |

When you use an induction hardened chrome plated rod, you gain excellent corrosion resistance. These rods act as a strong barrier against moisture and chemicals, which means you get longer service life and less downtime. Regular rods cannot match this level of protection. In aggressive environments like mining or marine settings, hardened chrome rods maintain their integrity and resist corrosion far better than untreated steel.

You also benefit from strict quality control. The plating thickness tolerance stays within ±0.005mm, verified by third-party testing. This consistency ensures that every rod meets the highest standards for corrosion resistance and durability.

Wear Resistance and Surface Durability

Wear resistance is another key property that sets hardened chrome rods apart. The hard chrome plating forms a tough, low-friction layer on the rod’s surface. This layer protects against abrasion, scratching, and surface fatigue. You get rods that maintain their shape and function even after long periods of use.

Metrics from laboratory tests show that hardened chrome rods have a chrome plating thickness between 10 and 30 microns and a minimum hardness of 800 HV. The micro Vickers hardness (HV0.3) reaches at least 850, according to ISO 6507. Surface roughness stays at or below Ra 0.2 micron, which means the rods have a smooth finish that reduces friction and wear.

| Metric | Specification |

|---|---|

| Surface Roughness | Maximum Ra 0.2 micron |

| Chrome Plating Thickness | 10–30 microns |

| Chrome Layer Hardness | Minimum 800 HV |

| Coating Hardness | Micro Vickers HV0.3 ≥ 850 (ISO 6507) |

| Corrosion Resistance | 72+ hours in neutral salt spray test (ASTM B117) |

You can measure wear resistance by looking at the weight loss of samples after wear tests. Hardened chrome rods show very low wear rates, which means they keep their dimensions and surface quality over time. The induction hardened chrome plated rod provides even greater wear protection because it combines a hardened core with a durable chrome plated surface.

You will notice that hard chrome plating not only improves wear resistance but also boosts durability. The rods withstand repeated cycles of pressure, friction, and impact. This makes them ideal for hydraulic systems, heavy equipment, and other demanding applications where you need long-lasting performance.

Tip: When you choose hardened chrome rods, you invest in durability, wear resistance, and corrosion resistance. These properties help your equipment run longer and reduce maintenance costs.

Surface Finish, Smoothness, and Oil Retention

When you look at a chrome plated steel rod, you notice the bright and mirror-like appearance. This is not just for looks. The chrome plated surface plays a big role in how the rod works in machines and equipment.

A smooth surface helps reduce friction. When you use a rod with a rough surface, it can cause seals to wear out quickly. This leads to leaks and more maintenance. A chrome plated surface, with a roughness as low as Ra 0.1–0.2 microns, feels almost like glass. You get a rod that moves smoothly inside hydraulic cylinders or other machinery.

Note: A smoother rod surface means less friction and less wear on seals. This helps your equipment last longer.

You also benefit from better oil retention. The chrome-plated finish holds a thin layer of oil on the rod. This oil acts as a barrier between the rod and the seal. It reduces heat and wear during movement. In hydraulic systems, this means you get better performance and fewer breakdowns.

Here is a table showing how surface roughness affects performance:

| Surface Roughness (Ra, μm) | Friction Level | Seal Wear Rate | Oil Retention |

|---|---|---|---|

| 0.1 – 0.2 | Very Low | Minimal | Excellent |

| 0.3 – 0.5 | Low | Low | Good |

| 0.6 – 1.0 | Moderate | Moderate | Fair |

| >1.0 | High | High | Poor |

You can see that a lower Ra value gives you better results. Most high-quality chrome plated steel rods meet or exceed the Ra 0.2 micron standard. This level of smoothness is important for high-speed and high-pressure applications.

A smooth chrome plated surface also helps prevent dirt and debris from sticking. This keeps the rod clean and reduces the risk of scratches. You get more reliable operation, even in dusty or dirty environments.

When you choose rods with a high-quality chrome-plated finish, you make sure your equipment runs smoothly. You spend less time on repairs and more time getting work done. This is why many industries trust chrome plated steel rods for their most important machines.

How Chrome Plated Steel Rod Properties Impact Performance

Improved Durability and Longevity in Industrial Use

When you use hardened chrome rods in your machinery, you gain a clear advantage in durability and long service life. These rods resist corrosion and wear, which means your equipment can operate longer without failure. The chrome plating forms a tough barrier that shields the steel core from moisture, chemicals, and abrasive particles. This protection is essential in industrial machinery, where harsh conditions can quickly damage untreated rods.

You can see the impact of these properties in dynamic seal tests. These tests measure friction forces, wear, and leakage at different pressures, speeds, and temperatures. The results show how hardened chrome rods outperform other materials in real-world applications. Here is a table that summarizes the findings:

| Test Parameter | Hardened Chrome Rods | Alternative Coatings |

|---|---|---|

| Pressure (bar) | 0–300 | 0–300 |

| Rod Velocity (m/min) | 0.1–4 | 0.1–4 |

| Oil Temperature (°C) | 30, 60, 80 | 30, 60, 80 |

| Seal Friction (N) | Low | Moderate/High |

| Wear Rate | Minimal | Higher |

| Leakage | Very Low | Moderate |

| Fatigue Resistance | Excellent | Good/Fair |

| Corrosion Resistance | Outstanding | Variable |

You benefit from these results in many applications. Hydraulic systems, presses, and industrial machinery all rely on hardened chrome rods for high durability and extended service life. The rods maintain their strength and performance even after thousands of cycles. You avoid frequent replacements and reduce downtime, which helps your operations run smoothly.

Note: Consistent durability means fewer breakdowns and less time spent on repairs. You keep your machinery running and your business productive.

Enhanced Load-Bearing Capacity and Impact Resistance

You need rods that can handle heavy loads and sudden impacts in demanding applications. Hardened chrome rods deliver high strength and wear resistance, making them ideal for construction, mining, and heavy equipment. The induction hardening process increases surface hardness, while the chrome plating adds another layer of protection against corrosion and wear.

Here are some key facts that show how these rods perform under stress:

- Induction hardening raises surface hardness to at least Rc 50, with a case depth of 0.050 inches or more. This gives you excellent impact and wear resistance.

- Chrome plating increases fatigue strength by raising the number of cycles needed for cracks to form. You get less plastic deformation and longer rod life.

- Materials like 42CrMo4 offer a minimum tensile strength of 610 N/MM² and yield strength of 355 N/MM². These numbers mean your rods can handle high loads without bending or breaking.

- Rockwell Hardness Testing and Rotary Wear Testing confirm the high durability and impact resistance of hardened chrome rods.

- Field tests in heavy machinery show a 20% increase in piston rod strength after chrome plating.

- Chrome plating thickness ranges from 51 to 127 μm. This range provides strong corrosion protection, as proven by salt spray and electrochemical tests.

- Fretting fatigue life improves by up to 60% with chrome plating. Your rods resist repeated stress cycles much better.

- The induction hardening process creates a hard surface and a tough core. This combination ensures high load-bearing capacity and resistance to deformation.

- Hardened chrome rods withstand heavy loads and harsh environments. You can use them in hydraulic cylinders and industrial machinery with confidence.

You see these benefits in many applications. Heavy equipment, presses, and hydraulic systems all require rods with high strength and impact resistance. Hardened chrome rods meet these needs and help your machinery perform at its best.

Reduced Maintenance and Operational Costs

When you choose hardened chrome rods, you lower your maintenance and operational costs. The rods’ corrosion resistance and wear resistance mean you spend less time and money on repairs. The chrome plating protects against rust, pitting, and surface damage. This protection keeps your machinery in top condition, even in tough environments.

You also reduce the risk of seal failure and oil leaks. The smooth surface of hardened chrome rods minimizes friction and wear on seals. Your hydraulic systems run more efficiently, and you avoid costly downtime. In industrial machinery, this reliability translates to higher productivity and fewer interruptions.

Many applications benefit from these cost savings. Manufacturing plants, automotive assembly lines, and construction sites all use hardened chrome rods to keep equipment running longer. You get extended service life and high durability, which means you can focus on your work instead of constant repairs.

Tip: Investing in hardened chrome rods pays off over time. You save money on maintenance, reduce downtime, and get more value from your machinery.

Consistent Operation in Harsh and High-Friction Environments

You often face tough conditions in industrial settings. Machines run for long hours. Dust, dirt, and moisture can attack metal parts. High pressure and fast movement create friction and heat. In these harsh environments, you need parts that keep working without fail. Hardened chrome rods give you this reliable operation.

When you use hardened chrome rods, you get a strong steel core with a hard chrome plating. This plating acts as a shield. It blocks moisture and chemicals, so corrosion cannot damage the rod. The chrome plating also gives the rod a smooth surface. This smoothness reduces friction, which means less heat and less wear on moving parts.

You see the benefits of hardened chrome rods in real-world tests. In one study, engineers tested chrome plated steel rods under dry sliding conditions. They used a special machine called a reciprocating tribometer. This machine moved the rods back and forth, simulating the way rods work inside hydraulic cylinders. The test also included periods with little or no oil, which is common in high-friction environments.

The results showed that the chrome plating helped the rods resist wear, even when oil was low. Microhardness measurements proved that the chrome layer stayed hard during the test. The rods showed some abnormal wear patterns, like extrusion and ploughing, especially where the chrome met softer materials. The coefficient of friction changed as the load increased, but the rods kept working. This shows that hardened chrome rods can handle sudden changes in pressure and friction.

You can trust hardened chrome rods to deliver consistent performance. The chrome plating gives you high corrosion resistance. This means the rods do not rust or pit, even when exposed to water or chemicals. The plating also keeps the rod surface smooth, so seals last longer and leaks are rare. You get steady operation, even when the environment is dirty or wet.

Here is a table that shows how hardened chrome rods perform in harsh and high-friction environments:

| Feature | Hardened Chrome Rods | Regular Steel Rods |

|---|---|---|

| Corrosion Resistance | Excellent | Poor |

| Plating Durability | High | Low |

| Strength | High | Moderate |

| Consistent Performance | Yes | No |

| Wear Resistance | High | Low |

| Maintenance Needs | Low | High |

Note: You get the best results when you use hardened chrome rods in places with high friction and risk of corrosion. The chrome plating protects the rod and keeps your machines running smoothly.

You also benefit from the strength of the steel core. The rod does not bend or break under heavy loads. The chrome plating adds another layer of protection, so the rod lasts longer. You spend less time fixing machines and more time getting work done.

You can see why many industries choose hardened chrome rods. The combination of strength, durability, corrosion resistance, and reliable plating makes them the top choice for harsh environments. You get consistent performance, even when conditions are tough.

Chrome Plated Steel Rods vs. Alternatives

Comparison with Non-Plated Steel Rods

When you compare hardened chrome rods to non-plated steel rods, you see clear differences in performance. Hardened chrome rods use hard chrome plating to create a tough, protective surface. This layer gives you much better resistance to corrosion and wear. In real-world tests, chrome plated rods last longer than nitrided or untreated steel rods. You can polish chrome plated rods easily, which helps maintain a smooth finish. Non-plated rods often snap without warning, while hardened chrome rods bend before breaking. This makes your equipment safer. More than half of nitrided rods in service need replacement because of corrosion, but hardened chrome rods show no such problems. You get a rod that stands up to daily use and keeps your machines running.

Comparison with Stainless Steel and Composite Rods

You might wonder how hardened chrome rods compare to stainless steel or composite rods. Stainless steel forms a self-healing chromium oxide layer. This layer protects against corrosion and needs little maintenance. Stainless steel costs more at first, but it lasts 15 to 20 years with almost no upkeep. Hardened chrome rods, with hard chrome plating, offer excellent surface hardness and a shiny finish. You get great wear resistance and chemical protection. Composite rods, like carbon-fiber-reinforced types, weigh 25–30% less than steel rods. This helps with fuel efficiency. Some coatings, such as chrome nitride or diamond-like carbon, reduce wear by 40–60% compared to hard chrome plating. Stainless steel rods with special coatings can last over 15 years in harsh environments. Laser cladding on steel rods increases operating hours by 72%. You see that each material has strengths, but hardened chrome rods with hard chrome plating give you a balance of hardness, corrosion resistance, and cost.

Here is a table to help you compare:

| Material / Treatment | Key Benefit | Typical Service Life |

|---|---|---|

| Hardened chrome rods (hard chrome plating) | High hardness, corrosion resistance | 5–10 years (typical use) |

| Stainless steel (with coatings) | Low maintenance, long life | 15–20 years |

| Composite rods | Lightweight, fuel savings | Varies |

| Laser-clad steel rods | Extended wear resistance | 72% longer than standard |

Induction Hardened Chrome Plated Rod vs. Standard Chrome Plated Rod

You get even more benefits when you choose an induction hardened chrome plated rod. This rod combines a hard chrome plating surface with a core that has been hardened by induction. The result is a rod that lasts up to three times longer than a standard rod. You can handle up to 30% more stress with an induction hardened chrome plated rod. The hard outer shell resists scratches, dents, rust, and chemicals. You spend less time on maintenance and enjoy fewer breakdowns. Industry reports show that machines using induction hardened chrome plated rods have more uptime and lower repair costs.

Here is a table to show the differences:

| Performance Metric | Induction Hardened Chrome Plated Rod | Standard Rod (Non-Hardened/Non-Chrome) |

|---|---|---|

| Service Life | Up to 3 times longer | Shorter |

| Stress Handling | 30% more | Lower |

| Wear Resistance | Excellent | Low |

| Corrosion Resistance | Outstanding | Poor |

| Maintenance Frequency | Low | High |

You see that the induction hardened chrome plated rod gives you the best mix of strength, durability, and low maintenance. When you need reliable performance, especially in tough environments, this rod stands out. You can trust hardened chrome rods with hard chrome plating to keep your equipment running smoothly and safely.

Real-World Applications and Benefits

Hydraulic and Pneumatic Cylinder Applications

You see chrome plated steel rods used in hydraulic and pneumatic cylinders across many industries. These rods give you high fatigue strength, which means you can use smaller diameters without losing durability. Stronger steels, like those in the Cromax line, help you lower piston rod costs by up to 30%. Most hydraulic cylinders work with low to moderate slenderness ratios, so the yield strength of the rod material matters for buckling resistance. Chrome plating is the most common surface treatment for piston rods. When you combine chromium with nickel, you get even better corrosion resistance, especially in harsh environments. Induction hardening boosts mechanical properties, letting you design slimmer rods that still handle high loads. You can trust these rods in precision equipment, where reliability and long service life are critical.

- Chrome plated steel rods resist corrosion from harsh media like seawater, making them reliable in hydraulic systems.

- Induction-hardened and chrome-plated rods reach high surface hardness (Rc58/60), perfect for high-pressure applications.

- Extensive fatigue testing proves their performance in demanding machinery.

Use in Industrial Machinery and Manufacturing Equipment

You find chrome plated steel rods in many types of industrial machinery and manufacturing equipment. These rods lower friction, which leads to smoother machine operation and less heat buildup. This extends the life of your machinery and reduces maintenance costs. You can re-plate worn parts to restore their original dimensions, which saves you money and keeps your equipment running. Chrome plated rods work well in precision equipment like injection molding machines and metal stamping presses. They also appear in robotics, where smooth and fast movement is essential for accuracy.

Tip: Using chrome plated rods in your machinery helps you achieve higher precision and efficiency.

- Chrome plated shafts have a low coefficient of friction, reducing heat and wear in repetitive movements.

- The rods offer natural resistance to rust, mold, and bacteria, making them suitable for medical and marine applications.

- You see these rods in pump shafts, rotors, cutting tools, punches, and bores, all requiring high precision.

Heavy Equipment, Construction, and Automotive Applications

You rely on chrome plated steel rods in heavy equipment, construction, and automotive applications. Induction hardening creates a surface hardness of HRC 55-60, which means longer service life and fewer replacements. Superior fatigue strength delays crack formation, even after millions of cycles. Hard chrome plating protects against corrosion, reducing pitting and extending performance in harsh environments. Higher buckling resistance allows you to design slimmer rods with higher load capacity. This means your machinery can handle more stress without increasing size.

| Improvement Aspect | Details |

|---|---|

| Wear Resistance | Induction hardening creates a hard surface, resulting in longer service life and fewer replacements. |

| Fatigue Strength | Delays crack formation under millions of cycles, enhancing durability. |

| Corrosion Protection | Hard chrome plating provides resistance critical for harsh environments. |

| Load Capacity & Design | Higher buckling resistance allows slimmer rod designs with higher load capacity. |

| Maintenance & Downtime | Reduced maintenance and downtime due to enhanced durability. |

| Applications | Used in construction, earthmoving, agricultural machinery, industrial automation, marine, mining, and heavy industry. |

| Material Grades & Coating | SAE 1045 and alloy steels (4140, 4340) with chrome plating thickness from 0.002″ to 0.010″. |

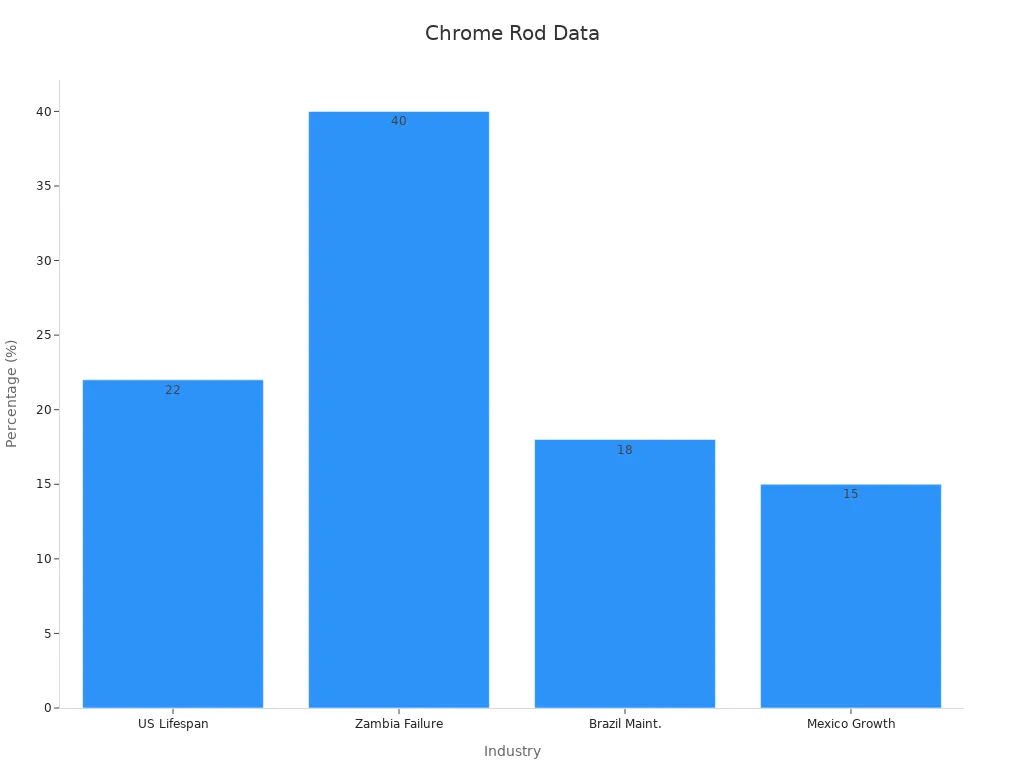

You see the benefits in real-world data. For example, laser hardening can increase product lifespan by 30-40%. In the US shale oil industry, stainless piston rods last 22% longer than carbon steel in fracking pumps. In Zambia mining, conventional rods have a 40% failure rate, showing the need for more durable chrome plated rods. In Brazil, modernizing hydraulic harvesters with stainless rods reduces downtime by 18%. In Mexico, the automotive sector sees 15% annual growth in stainless rod use for robotic press lines.

You can count on chrome plated steel rods to deliver precision, durability, and efficiency in your machinery and precision equipment. These applications show why so many industries trust chrome plated rods for their most demanding needs.

Specialized Uses in Aerospace, Printing, and Packaging Industries

You see chrome plated steel rods play a vital role in specialized industries like aerospace, printing, and packaging. These industries demand high performance and reliability in all applications. You need materials that can handle stress, resist corrosion, and deliver consistent results. Chrome plated steel rods meet these needs with their unique properties.

In aerospace, you find these rods in critical applications such as aircraft landing gear. The landing gear must support heavy loads and withstand harsh conditions. Chrome plating gives the rods extra durability and corrosion protection. This means you get longer service life and fewer failures. The Market Research Future report highlights how aerospace applications rely on chrome plated steel rods for their strength and wear resistance. You can trust these rods to maintain precision in every landing and takeoff.

Printing and packaging industries also depend on chrome plated steel rods. You see them used in printing wear roll surfaces and other moving parts. These applications require high precision and smooth operation. Chrome plating creates a surface that resists wear and keeps the equipment running smoothly. You get better print quality and less downtime. In packaging, machines use chrome plated rods for cutting, sealing, and moving products. The rods’ precision ensures that every package meets strict standards.

Here is a quick look at how chrome plated steel rods support these industries:

- Aerospace: Used in landing gear, actuators, and control systems for precision and safety.

- Printing: Found in rollers and guides, where precision and wear resistance are essential.

- Packaging: Used in cutting blades, guides, and moving parts for high-speed applications.

Tip: When you choose chrome plated steel rods for specialized applications, you ensure your precision equipment works reliably and efficiently.

You benefit from the enhanced durability, wear resistance, and corrosion protection that chrome plated steel rods provide. These features make them the top choice for precision applications in aerospace, printing, and packaging.

You gain clear benefits when you choose chrome plated steel rods for your equipment. These rods offer:

- Surface hardness up to 70 HRC, which boosts wear resistance and keeps your machines running longer.

- Excellent corrosion resistance that protects against harsh chemicals and moisture.

- A sacrificial wear layer that lets you re-plate rods, reducing downtime and saving on maintenance.

- Microcracks in the plating that hold lubricants, lowering friction and further extending equipment lifespan.

These benefits help you cut costs, reduce repairs, and keep your operations efficient. For any high-performance or demanding application, chrome plated steel rods deliver the reliability you need.

FAQ

What makes chrome plated steel rods better for hydraulic systems?

You get higher surface hardness and corrosion resistance with chrome plated steel rods. These properties help your hydraulic cylinders last longer and work smoothly, even in tough environments.

How does chrome plating improve wear resistance?

Chrome plating creates a hard, smooth layer on the rod. This layer reduces friction and protects against scratches. You see less wear and fewer breakdowns over time.

Can you re-plate chrome plated steel rods?

Yes, you can re-plate these rods. When the chrome layer wears down, you restore the surface by applying a new chrome coating. This process extends the rod’s service life.

What is the typical hardness of a chrome plated steel rod?

Most chrome plated steel rods reach a surface hardness of 65–72 HRC (about 940–1210 HV). This high hardness helps resist dents and scratches during heavy use.

Are chrome plated steel rods suitable for outdoor or marine use?

You can use chrome plated steel rods outdoors or in marine settings. The chrome layer protects against rust and corrosion, even when exposed to water or chemicals.

Tip: Always check the chrome thickness and quality for the best performance in harsh environments.