The metal powder market is projected to hit an estimated $18.7 billion by 2025, fueling significant growth in the powdered metallurgy sector. The metal powder pressing process is a key technique that transforms powdered materials into solid, functional parts. Choosing the right powder pressing method involves carefully balancing the complexity of the component with the overall cost, as this powder metallurgy process presents a critical trade-off between performance and affordability.

The main techniques for this process include conventional powder pressing, isostatic pressing, and metal injection molding. For highly intricate designs, metal injection molding is often an excellent choice. Ultimately, selecting the best method depends on the specific requirements of your project.

Key Metrics for Comparing Powder Pressing Techniques

Engineers must evaluate several key metrics to select the optimal powder pressing process. The right choice depends on the specific performance and geometric needs of the final component. A careful review of these factors ensures the selected method aligns with both budget and application requirements.

Part Complexity and Design Freedom

Each powder pressing process offers a different level of design freedom. Cold Pressing, for example, is best suited for parts with simpler geometries. This process is ideal for producing components such as:

- Balls, tubes, and rods

- Nozzles and fuse tubes

- Spark plug insulators

Metal Injection Molding (MIM), however, provides significantly more design freedom. This method excels at producing parts with high complexity, allowing for features that are difficult to achieve with other techniques. MIM enables the creation of asymmetric and irregular features in a single part.

MIM is an excellent choice for parts requiring intricate internal channels, thin walls, complex angles, or fine surface details like logos and threads. This capability often eliminates the need for secondary machining operations.

Final Density and Porosity

The final density of a part is a critical factor that directly impacts its performance. Porosity, or the presence of small voids, can reduce a component’s overall integrity. The Cold Pressing process typically yields parts with a relative sinter density between 93% and 95.65%. While suitable for many applications, this leaves some inherent porosity. In contrast, a MIM part is considered fully metallic after sintering and shows full density, which is essential for high-performance applications.

Mechanical Strength and Hardness

A part’s density directly influences its mechanical strength and hardness. Components with higher density and lower porosity exhibit superior performance characteristics. A manufacturing process that achieves near-100% density will produce parts with maximum strength. Therefore, methods like MIM and HIP are preferred for critical applications where failure is not an option. The design of the part and the chosen powder pressing technique work together to determine the final component’s durability.

Dimensional Accuracy and Tolerances

Dimensional accuracy is crucial for ensuring parts fit and function correctly. Each powder pressing method offers different levels of precision.

- Cold Pressing: This process generally produces parts with good, but not exceptional, tolerances. It is well-suited for components where minor variations are acceptable.

- Hot Isostatic Pressing (HIP): The HIP process significantly improves the dimensional consistency of a part by eliminating internal voids. It helps achieve tighter tolerances than cold pressing alone.

- Metal Injection Molding (MIM): MIM delivers excellent dimensional accuracy. This process is ideal for small, complex parts requiring tight tolerances, often rivaling those achieved through precision machining.

Production Volume and Speed

The choice of a powder pressing process often depends on the required production volume and speed. A method’s efficiency directly impacts project timelines and overall cost.

Cold pressing is a fast and efficient process for high-volume production of simple shapes. Its rapid cycle times make it a go-to for automotive and industrial applications. In contrast, HIP is a slower, batch-based process. Its primary use is for enhancing part properties rather than for high-speed production.

Metal Injection Molding bridges the gap. It is designed for high-volume production of complex parts. Once the initial tooling is complete, the MIM process can produce thousands of parts quickly and consistently. This makes it highly scalable for large orders.

Tooling and Per-Part Cost

Tooling and per-part cost are fundamental economic factors in selecting a powder pressing technique. The initial investment in tooling can vary significantly between methods, directly influencing the final cost per component.

Cold pressing typically involves lower tooling costs, making it economical for simpler parts, even at lower volumes. The real savings, however, appear in high-volume runs where the process efficiency drives down the per-part price.

MIM involves a higher upfront tooling cost. However, this initial investment is offset by a lower per-part cost as production volumes increase. This relationship demonstrates how economies of scale can lead to significant cost savings. For large production runs, MIM often provides the most economical solution for complex components. The right choice depends on balancing part complexity with the required quantity. This balance is key to achieving long-term savings.

| Objective | Best When | Mold Price | Part Price |

|---|---|---|---|

| Validate Design | Lifetime volumes below 2,000 parts | Lower | Higher |

| On-Demand Production | Lifetime volumes exceed 2,000 parts | Higher | Lower |

Ultimately, a higher initial investment in the MIM process can unlock substantial savings on high-volume orders, making it a strategic choice for long-term production.

Material Selection and Compatibility

The choice of metal powder directly influences the selection of a powder pressing technique. Each method works best with specific materials. Cold pressing, for example, has limitations. It struggles to compact very hard powders and is generally incompatible with hard ceramic oxides. This makes it unsuitable for certain high-strength applications.

In contrast, Hot Isostatic Pressing (HIP) handles a much wider range of materials. This process is excellent for densifying high-performance metals and ceramics. Materials successfully processed with HIP include:

- Superalloys like nickel, cobalt, and titanium alloys.

- High-temperature metals such as tungsten and high-speed steels.

- Advanced ceramics, including Alumina (Al2O3) and Silicon Nitride (Si3N4).

Metal Injection Molding (MIM) also offers great flexibility, working with a vast library of metals to create complex components. The right powder pressing process ensures compatibility and optimal performance.

Required Secondary Operations

The initial forming process is often just one step in manufacturing a finished part. Many components require secondary operations to meet final specifications. Parts made via cold pressing frequently need additional work. These steps are necessary to add features, improve tolerances, or enhance material properties.

Common secondary operations for cold-pressed parts include sizing to refine dimensions, machining to add threads or grooves, and resin impregnation to seal porosity. Heat treatments are also used to increase hardness and strength.

These extra steps add time and cost to the overall production. A key advantage of a process like MIM is its ability to produce net-shape parts. This capability often eliminates the need for extensive secondary machining, improving overall material efficiency. Choosing a powder pressing method that minimizes these extra steps can lead to significant savings.

The Role of Cold Pressing in Powdered Metallurgy

Cold pressing is a cornerstone of the powdered metallurgy industry. This technique excels in specific manufacturing scenarios. It provides a reliable and efficient method for producing a wide range of components. The process involves the uniaxial or isostatic compaction of powdered metal at room temperature.

High-Volume, Simple Shapes

The cold powder pressing process is unmatched for producing simple parts at high speeds. Production rates often exceed 300 parts per minute. This makes the process ideal for medium to high volumes, typically starting in the thousands. The rapid compaction of powdered materials allows for the creation of consistent, straightforward geometries. This efficiency makes it a preferred method in the automotive sector.

Common automotive parts made with this powder pressing technique include:

- Gears, shafts, and fasteners

- Structural pillars and reinforcements

- Suspension components and sensor brackets

Cost-Driven Applications

Manufacturers choose cold pressing for its significant economic advantages. The high-speed nature of the process translates directly into lower labor costs and greater throughput, generating substantial savings. This method is a cost-effective alternative to machining when producing large quantities of parts. The initial tooling investment is often lower than other methods. This lower upfront cost, combined with rapid cycle times, drives down the final part cost. The overall savings make this powder metallurgy process highly attractive for budget-conscious projects.

Moderate Performance Needs

Cold pressing is the ideal choice for applications that require good, but not maximum, performance. The compaction process creates parts with moderate density and strength. These properties are perfectly suitable for many industrial and consumer products. While the parts are not fully dense, they meet the specifications for countless components that do not face extreme stress or wear. The final compaction step determines the part’s integrity. This balance of performance and economy makes cold powder pressing a versatile and widely used manufacturing solution.

When to Use Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a specialized powder metallurgy process that subjects components to high temperatures and uniform pressure. This technique is essential for applications demanding the highest material integrity. The process uses an inert gas to apply pressure, ensuring uniform compaction from all directions.

Achieving Maximum Density

The primary goal of isostatic pressing is to eliminate internal porosity. This process achieves near-perfect material density. Industry benchmarks show that the HIP process can produce parts with a relative density greater than 99.9%. The combination of intense heat and pressure forces powdered particles to bond, creating a solid, void-free structure. This level of compaction is critical for producing high-density components that outperform parts made with other methods.

Critical, High-Performance Components

Engineers rely on isostatic pressing for components where failure could have catastrophic consequences. The superior density and mechanical properties make it the top choice for safety-critical industries. This powder pressing technique ensures parts meet the highest performance standards.

Key applications include:

- Aerospace: Turbine blades, engine parts, and structural elements for aircraft and space vehicles.

- Medical: Orthopedic implants for hips and knees, dental implants, and surgical tools that require exceptional strength and biocompatibility.

Enhancing Parts from Other Methods

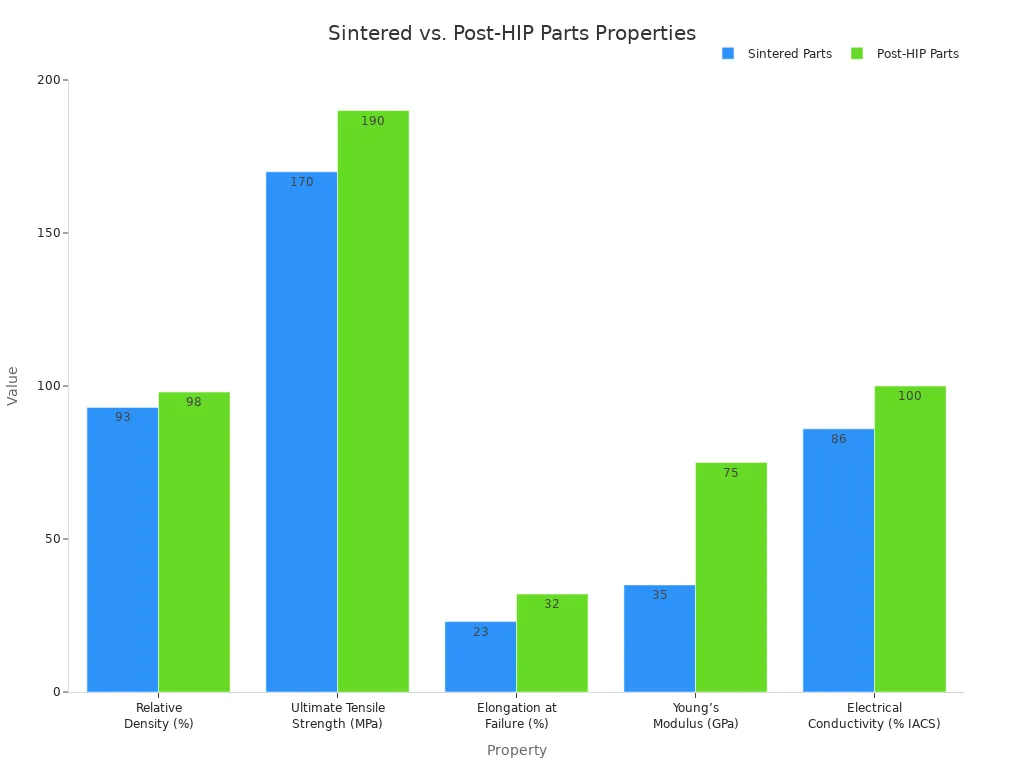

Hot Isostatic Pressing is also a powerful secondary operation. It enhances parts initially formed through other methods, such as casting or additive manufacturing. This final compaction step significantly improves the mechanical properties of a powdered metal component. The isostatic pressing process closes internal voids, boosting strength, toughness, and fatigue resistance. This powder pressing method turns a good part into a great one. The improvements from this powder pressing technique are clear.

| Property | Sintered Parts | Post-HIP Parts |

|---|---|---|

| Relative Density | 93% | 98% |

| Ultimate Tensile Strength | 170 MPa | 190 MPa |

| Elongation at Failure | 23% | 32% |

| Young’s Modulus | 35 GPa | 75 GPa |

| Electrical Conductivity | 86% IACS | 100% IACS |

The Advantages of Metal Injection Molding

Metal injection molding is a transformative powder metallurgy process. It combines the design freedom of plastic injection molding with the strength of metal. This technique excels where other powder pressing methods fall short, offering unique benefits for high-complexity components. The process uses fine powdered metal mixed with a binder to create a feedstock, which is then molded and sintered.

High-Volume, Complex 3D Parts

Metal injection molding is the premier choice for the high-volume production of parts with significant geometric complexity. The process allows for a level of design freedom that is difficult to achieve with conventional powder pressing. This capability makes it ideal for manufacturing small, intricate components in industries where precision is paramount. The initial compaction of the feedstock into the mold captures every detail.

For example, watchmakers use metal injection molding to create high-end components with exceptional detail.

- Bezels: The process produces durable stainless steel bezels with textured finishes or integrated numbers.

- Dials: It enables the creation of dials with detailed patterns and multiple levels.

- Clasps and Bands: MIM manufactures strong, wear-resistant clasps and bands from materials like 316L stainless steel.

Component Consolidation

A key advantage of metal injection molding is part consolidation. Engineers can redesign multi-part assemblies into a single, robust component. This design approach simplifies manufacturing and reduces assembly costs. A single part is often stronger and more reliable than an assembly of multiple pieces. For instance, a blade clamp for a power tool was successfully re-engineered from a complex assembly into one solid part using this process. This change improved the tool’s durability while streamlining production. The final compaction during sintering ensures the consolidated part has excellent mechanical properties.

Superior Surface Finish

The metal injection molding process delivers parts with an outstanding surface finish. The fine powdered metal used in the feedstock allows the mold to create smooth, detailed surfaces that often require no secondary polishing. This net-shape capability is a major benefit, reducing post-processing steps and saving both time and money. The final compaction step in the furnace creates a dense part with a clean appearance, making it perfect for visible components in consumer electronics, automotive interiors, and medical devices.

The Future of the Metal Powder Pressing Process

The metal powder pressing process continues to evolve with exciting technological advancements. Innovations in materials, manufacturing methods, and automation are shaping the future of the industry. These developments promise to enhance part performance, expand design possibilities, and improve overall production efficiency. The future of powder pressing lies in smarter, more integrated systems.

Integration with Additive Manufacturing

Hybrid manufacturing is creating powerful new workflows. Companies now combine additive manufacturing with traditional powder pressing techniques. For example, Hot Isostatic Pressing (HIP) is used as a finishing step for parts made with binder jetting. This hybrid process addresses the internal voids common in 3D-printed metal parts. The result is a component with nearly perfect density.

This post-processing step delivers significant performance gains. Studies on binder-jetted tool steel show clear benefits after HIP treatment:

- Sintered density increases from around 92% to over 99%.

- Hardness improves by as much as 45%.

- Compressive strength rises by up to 65%.

Advancements in Powder Materials

Material science is unlocking new potential for powder metallurgy. Researchers are designing novel materials like high-entropy alloys (HEAs). These alloys mix multiple elements in equal or near-equal amounts to create materials with exceptional properties. Scientists can produce HEAs using a powder pressing method involving uniaxial compaction and sintering.

Refractory HEAs are especially promising for high-temperature applications. They maintain their stable structure and strength under extreme heat. While first developed through casting, the powder pressing process is becoming a key alternative for advancing these powerful new alloys.

Automation in Process Control

Automation is revolutionizing the factory floor. Advanced robotics and smart sensors are making the metal powder pressing process more reliable and consistent. Automated systems handle material loading, part transfer, and quality inspection with high precision. Real-time data monitoring allows operators to track every stage of production. This control minimizes defects and boosts manufacturing efficiency. This automated process ensures every component meets exact specifications with minimal human error.

Choosing the right metal powder pressing process requires balancing performance, complexity, and cost. Cold powder pressing is the go-to for simple, high-volume parts. Isostatic pressing is essential for critical applications demanding superior properties. Metal injection molding excels at producing small, intricate parts in high volumes. This guide helps evaluate each powder pressing technique within powdered metallurgy. Understanding the metal powder pressing process ensures you select the best metal powder pressing option, like metal injection molding, for your project.

FAQ

How do I choose the right process for my project?

Engineers evaluate three key factors: part complexity, performance requirements, and total budget.

- Cold Pressing: Best for simple, high-volume parts where cost is the main driver.

- HIP: Essential for critical parts needing maximum density and strength.

- MIM: Ideal for complex, high-volume parts with excellent finishes.

What materials are compatible with powder metallurgy?

Material choice depends on the specific powder pressing technique. Cold pressing works well with iron and copper powders. HIP and MIM handle a much wider range of materials. This includes high-performance superalloys, titanium, stainless steels, and even some advanced ceramics for specialized applications.

Is the powder pressing process expensive?

The cost varies by method and volume. Cold pressing often has lower initial tooling costs. MIM has a higher tooling investment but delivers a lower per-part price on large production runs. The total quantity of parts needed determines the most economical powder pressing solution.

Can these parts be used in the automotive industry?

Yes, the automotive sector is a primary user of these technologies. Manufacturers produce many components like gears, structural pillars, and suspension parts. The processes create strong and reliable components that meet the industry’s demanding standards for performance and cost-effectiveness.