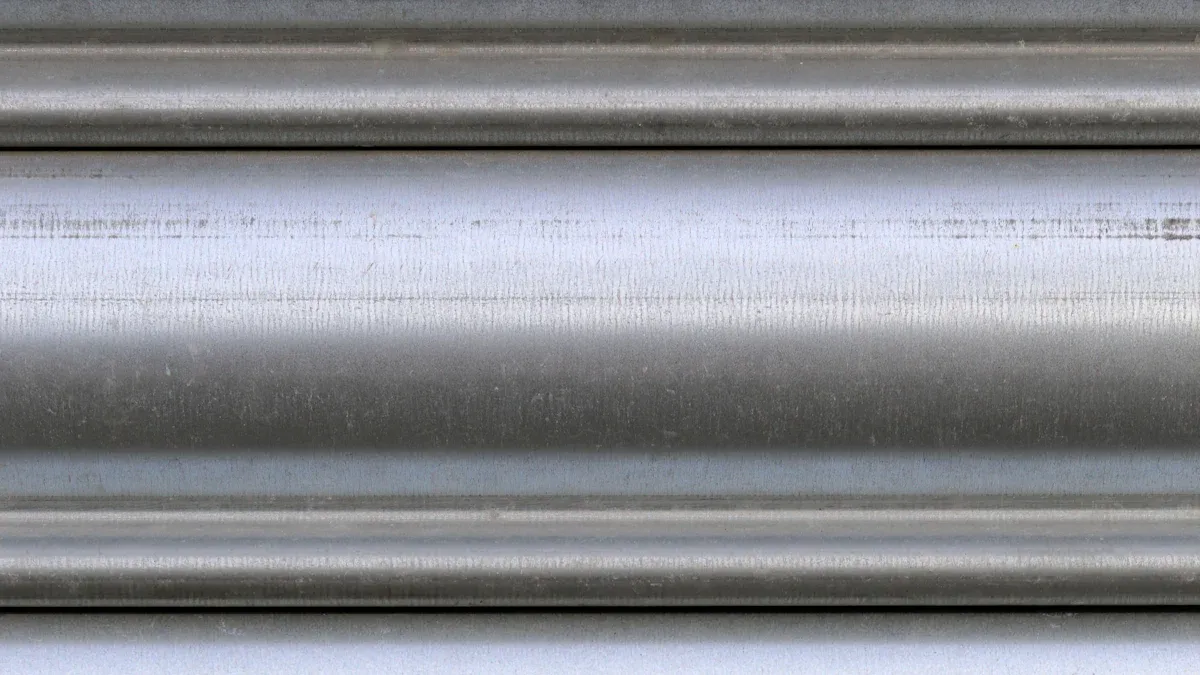

When you use a chrome hydraulic rod, you want strong corrosion resistance. Hard chrome plating on a chrome hydraulic rod creates a tough, non-porous layer that blocks water and chemicals. This barrier keeps the steel core of the chrome hydraulic rod safe from damage. You get better resistance to rust and longer use. The special finish gives your chrome hydraulic rod enhanced durability. Many industries trust chrome hydraulic rods for their high corrosion resistance and strong performance in rough conditions. You can rely on a chrome hydraulic rod for lasting results.

Corrosion Challenges for Chrome Hydraulic Rods

Causes of Corrosion in Hydraulic Cylinder Rods

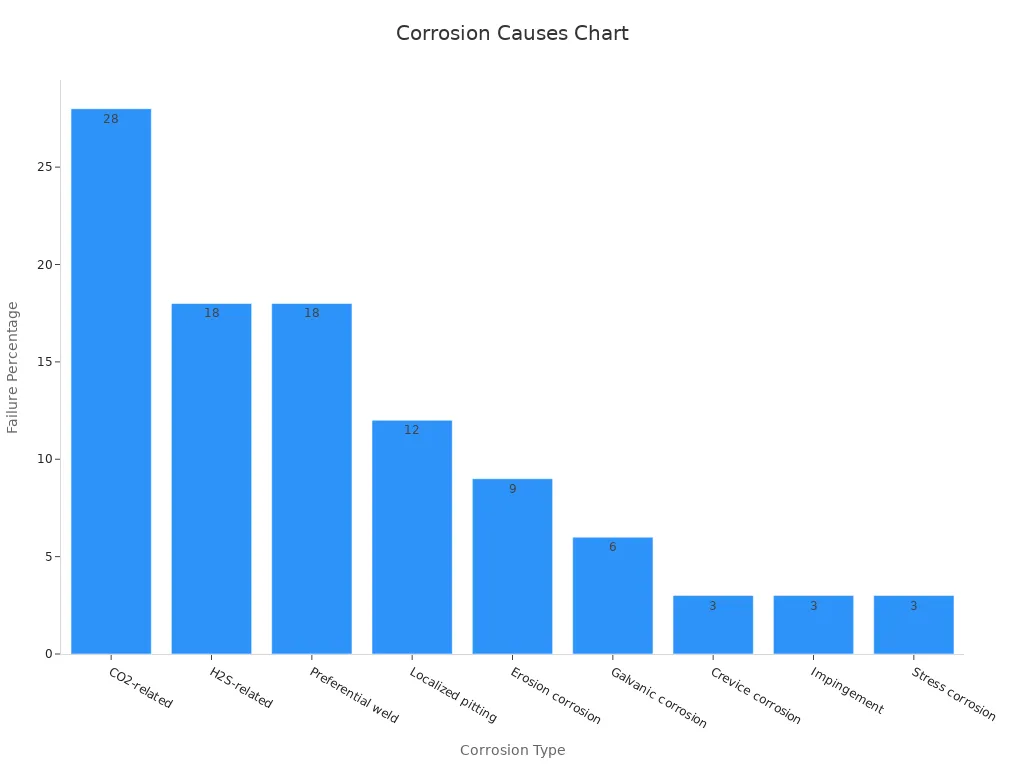

You face many challenges when you use a chrome hydraulic rod in tough environments. Corrosion is one of the biggest threats. Research shows that chrome hydraulic rods often suffer from adhesive wear, pitting, and crack growth. These problems start when water, chemicals, or acids touch the metal surface. When you use your hydraulic cylinder rod in places with CO2 or other acids, the risk of corrosion goes up. CO2 in water forms carbonic acid, which lowers the pH and starts to eat away at the metal. Other acids, like hydrochloric acid and hydrofluoric acid, can also attack the rod. This process creates small pits and cracks that grow over time.

Here is a table showing the main causes of corrosion and how often they lead to failure:

| Corrosion Type | Approximate Failure Percentage |

|---|---|

| CO2-related | 28% |

| H2S-related | 18% |

| Preferential weld | 18% |

| Localized pitting | 12% |

| Erosion corrosion | 9% |

| Galvanic corrosion | 6% |

| Crevice corrosion | 3% |

| Impingement | 3% |

| Stress corrosion | 3% |

Tip: If you work in oil and gas or other harsh industries, you should pay close attention to these causes. They can quickly damage your chrome hydraulic rod if left unchecked.

Impact of Corrosion on Hydraulic System Performance

Corrosion does more than just make your chrome hydraulic rod look bad. It can shorten the life of your equipment and cause breakdowns. Studies show that steel tubing in hydraulic systems can last about five years in normal conditions. In harsher places, corrosion can cut that time to less than one year. When corrosion attacks the rod, it creates pits and rough spots. These weak points can lead to leaks, loss of pressure, and even system failure. If you use rods made with higher levels of chromium, nickel, and molybdenum, you get better resistance and longer service life. Choosing the right materials and coatings helps you avoid costly repairs and keeps your system running smoothly.

How Hard Chrome Plated Rods Prevent Corrosion

Physical Barrier and Non-Porosity

When you choose hard chrome plated rods, you get a strong shield against harmful elements. The hard-chrome plating creates a dense, non-porous layer on the rod’s surface. This layer acts as a physical barrier that blocks water, oxygen, and chemicals from reaching the steel underneath. You can see the benefits in real-world tests:

- Salt spray tests show that dense, homogeneous coatings with higher TEOS content (10%) provide excellent protection. These coatings show almost no scribe creep, which means corrosion cannot spread easily.

- Less dense coatings with lower TEOS content (2.5%) perform poorly. They allow more corrosion because they have more gaps and are less uniform.

- Corrosion often starts at defects in the coating. When water or chemicals find a way through, they attack the metal and cause damage.

- The dense coating reduces oxygen from reaching the metal. This slows down the reactions that cause corrosion.

- Studies show that a continuous, non-porous barrier is key to stopping corrosion. The same principle applies to hard chrome plated rods, which rely on their dense surface to keep your equipment safe.

You can trust hard-chrome plating to give your hydraulic rods a reliable defense in tough environments.

Chemical Resistance and Surface Hardness

Hard chrome plated rods offer more than just a physical shield. You also get outstanding chemical resistance and surface hardness. These features help your rods last longer, even in harsh conditions. In field tests, NiKrom III coatings on hydraulic rods survived up to five times longer than standard hexavalent chrome coatings in copper mines. This shows how hard-chrome plating stands up to aggressive chemicals and tough use.

- The surface structure and hardness of NiKrom III match those of standard hard-chrome plating. You can use these rods with existing seals and designs without worry.

- The coating process keeps the rod’s mechanical properties and fatigue life intact. You do not need extra heat treatment.

- Hard chrome plated rods resist acids, alkalis, and other corrosive agents. This means you get better corrosion resistance and less risk of damage.

- The hard surface also reduces wear and tear, so your rods stay smooth and strong over time.

With hard-chrome plating, you get a rod that resists chemicals, stays hard, and keeps your hydraulic system running smoothly.

Microcrack Structure and Oil Retention

You may notice that hard chrome plated rods have a network of tiny microcracks on their surface. These microcracks help spread out mechanical strain and improve lubrication. When oil fills these cracks, it creates a thin layer that reduces friction and reduces wear and tear on your hydraulic rods. This means your equipment runs more smoothly and lasts longer.

However, scientists have used advanced microscopes to study these microcracks. They found that the cracks are very narrow and do not hold much oil. Instead, hard-chrome plating reduces the roughness of the rod’s surface. This smoother surface helps oil spread out faster and more evenly. Better oil coverage means less direct contact between metal parts, which reduces friction and helps prevent damage.

The microcrack structure in hard chrome plated rods gives you two main benefits. First, it helps distribute stress and keeps the rod from cracking under pressure. Second, it improves how oil spreads across the surface, which supports corrosion resistance by keeping the rod well-lubricated. You get a rod that not only lasts longer but also performs better in demanding conditions.

Benefits of Hard Chrome Plated Rods in Hydraulic Systems

Extended Service Life and Durability

When you use hard chrome plated rods in your hydraulic systems, you notice a big difference in how long your equipment lasts. The chrome layer on these rods forms a tough shield that blocks rust and chemical attacks. This protection means your rods do not wear out quickly, even when you use them in harsh places like mines or factories. The smooth surface of hard chrome plated rods also reduces friction, so moving parts glide easily and do not grind against each other. This feature improves durability and helps your rods keep their shape and strength for a long time.

You can trust hard chrome plated rods to handle high pressure and heavy loads without bending or breaking. The hard chrome layer resists scratches and dents, so your rods stay in top shape. Many companies choose these rods because they want equipment that works well year after year. You get more value from your investment because you do not need to replace rods as often.

Note: The benefits of hard chrome plated rods include a longer service life and less risk of sudden failure. This means you can count on your hydraulic system to work when you need it most.

Lower Maintenance and Downtime

Hard chrome plated rods help you save time and money on maintenance. The tough chrome finish keeps dirt, water, and chemicals away from the steel inside. This means you do not have to stop your machines as often to clean or fix the rods. The smooth surface also makes it easy to wipe off any dust or grime that builds up during use.

You will notice that your hydraulic system runs longer between repairs. The rods do not rust or pit easily, so you avoid leaks and pressure loss. When you use hard chrome plated rods, you cut down on the number of times you need to replace parts. This leads to less downtime and more time spent getting work done.

Here are some ways hard chrome plated rods reduce maintenance:

- The chrome layer stands up to wear and tear, so you do not need to polish or re-coat the rods often.

- The rods keep their size and shape, which helps seals last longer and prevents leaks.

- You spend less on spare parts and labor because the rods stay in good condition.

Improved Reliability and Safety

You want your hydraulic system to work safely and reliably every day. Hard chrome plated rods give you peace of mind because they perform well under tough conditions. These rods pass strict quality tests for size, surface smoothness, chrome thickness, corrosion resistance, and hardness. Most hard chrome plated rods reach a hardness of 900 to 1000 HV, which means they can handle heavy use without wearing out.

You also get better system stability with hard chrome plated rods. The rods carry heavy loads and high pressure without bending or breaking. The smooth chrome finish lowers friction, so your system uses less energy and parts last longer. You do not have to worry about sudden breakdowns or dangerous failures.

- Hard chrome plated rods offer excellent wear resistance, which extends the life of your hydraulic system.

- The chrome coating protects against rust and chemical damage, even in harsh environments.

- The rods support high loads and pressure, keeping your system stable and safe.

- You spend less time fixing problems and more time using your equipment.

Tip: Always choose hard chrome plated rods that meet international standards like ISO, DIN, or ASTM. This ensures you get rods that are tested for quality and safety.

The benefits of hard chrome plated rods go beyond just lasting longer. They help you work safely, reduce costs, and keep your hydraulic systems running smoothly.

Hard Chrome Plated Rods vs. Alternative Coatings

Comparison with Unplated Hydraulic Cylinder Rods

When you compare hard chrome plated rods to unplated hydraulic cylinder rods, you see clear differences in performance. Hard chrome plated rods form a passive chromium oxide layer that protects against rust and wear. This layer blocks water and chemicals from reaching the steel. Unplated rods do not have this protection, so they corrode faster and need more repairs.

Here is a table that shows how hard chrome plated rods improve durability:

| Durability Factor | Improvement with Hard Chrome Plating | Practical Benefit |

|---|---|---|

| Corrosion Protection | 500+ hours salt spray resistance | Significantly extended operation in harsh environments compared to unplated rods |

| Wear Resistance | 2-10× improvement | Extended maintenance intervals and longer component life |

| Surface Hardness | 65-70 HRC typical | Resistance to deformation and impact, superior to unplated rods |

You get longer service life, less seal wear, and fewer breakdowns when you use hard chrome plated rods. This makes them a smart choice for tough jobs.

Comparison with Other Coating Technologies

You may also consider other coating options for hydraulic rods, such as HVOF (High Velocity Oxygen Fuel) or LMD (Laser Metal Deposition). Research shows that HVOF CrC–NiCr coatings can offer even better wear resistance and lower friction than hard chrome plated rods. These coatings use fine powder feedstock and advanced spraying methods. They create a different surface texture, which you need to measure with 3D tools.

Tests show that HVOF and LMD coatings can match or beat hard chrome plated rods in some areas, especially when you use special lubrication systems. These alternatives are also more environmentally friendly. However, hard chrome plated rods remain popular because they are proven, reliable, and easy to use in many applications of hard chrome plated rods.

Cost-Effectiveness and Long-Term Value

When you look at cost and value, hard chrome plated rods stand out. You might pay more at first, but you save money over time. Here are some reasons why:

- Hard chrome plated rods last longer, so you replace them less often.

- You spend less on repairs and maintenance because of their high load bearing capacity and strong corrosion protection.

- Fewer breakdowns mean less downtime and more work done.

- You can choose the right coating thickness for your needs, which helps balance cost and performance.

Many industries trust hard chrome plated rods for their durability and long-term savings. They also offer better safety and lower risk of failure compared to other coatings.

Selecting Hard Chrome Plating for Chrome Hydraulic Rods

Key Factors in Choosing Hard Chrome Plating

When you select hard chrome plating for your hydraulic rods, you need to look at several important factors. These factors help you get the best performance and longest life from your equipment. Here is what you should consider:

- Material Properties: Check the strength, hardness, and corrosion resistance of both the rod and the coating. Steel or aluminum alloys with hard chrome plating give you better wear resistance.

- Operating Conditions: Think about the pressure, speed, stroke, and load type your rods will face. These conditions affect how much stress and heat your rods must handle.

- Environmental Factors: Look at the temperature, humidity, dust, chemicals, water, salt, and sunlight in your work area. These can cause corrosion or damage if you do not choose the right coating.

- Performance Requirements: Decide how much efficiency, reliability, and smoothness you need. The coating should help your system run quietly and accurately.

- Cost-Benefit Analysis: Weigh the upfront and ongoing costs against benefits like less maintenance and longer service life.

- Preparation Processes: Make sure the manufacturing process of hard chrome plated rods includes proper preparation before and after plating. Good preparation improves corrosion resistance and reduces seal leakage.

Tip: Always match the coating to your specific needs. This helps you avoid problems and get the most value from your investment.

Maintenance and Inspection Best Practices

To keep your hard chrome plated rods working well, you need to follow good maintenance and inspection steps. These steps help you spot problems early and keep your system safe.

- Inspect rods visually under good lighting. Use a magnifier if needed.

- Check critical areas with a microscope before plating.

- Use magnetic particle inspection to find cracks.

- Try dye-penetrant tests to reveal pits or small cracks.

- Use ultrasonic flaw detection for hidden voids or laminations.

- Measure surface roughness after polishing or blasting. This prevents contamination and leakage.

- Pre-machine rods to the right size for chrome plating thickness.

- Work closely with your plating provider to keep the coating even.

- Use micrometers or coordinate measuring machines for accurate checks.

- Prepare the surface well to help the plating stick and last.

- Use the right machining tools and speeds to avoid damaging the plating.

You should also run friction and leak endurance tests to make sure the rods meet your system’s needs. If you find deep pits, bends, or heavy scoring, replacement may be faster and more cost-effective than re-chroming.

Note: Share inspection duties among your team at every stage—grinding, plating, and cleaning. Careful checks before plating help you avoid costly rework and keep your rods in top shape.

You gain unmatched corrosion resistance when you choose hard chrome plating for your hydraulic rods. This protective layer keeps your equipment strong in harsh environments. You see these key benefits:

- Longer service life, proven by salt spray tests showing over 500 hours of protection

- Lower maintenance needs, which saves you time and money

- Improved system reliability, so your hydraulic equipment works when you need it

For the best performance and value, select hard chrome plating to protect your hydraulic cylinder rods.

FAQ

What is hard chrome plating?

Hard chrome plating adds a thick layer of chromium to a metal rod. You get a tough, shiny surface that resists rust and wear. This process uses electroplating to bond the chrome tightly to the rod.

How long does hard chrome plating last on hydraulic rods?

You can expect hard chrome plating to last over 500 hours in salt spray tests. Many rods work for years in tough environments. Regular inspection and cleaning help you get the longest life from your rods.

Can you repair a damaged hard chrome plated rod?

Yes, you can repair minor damage. You may polish small scratches or re-plate the rod if needed. Deep pits or heavy scoring often require full replacement for best performance.

Why do industries prefer hard chrome plated rods?

Industries choose hard chrome plated rods because you get strong corrosion resistance, high surface hardness, and long service life. These rods help you reduce maintenance costs and keep your hydraulic systems running smoothly.

Tip: Always follow the manufacturer’s care instructions to maximize rod performance and safety.