You can unlock the best performance suspension for your vehicle. Upgrading your shock absorber piston is one of the most effective enhancements you can make. High-flow designs, including multi-port and tunable pistons, offer superior fluid control compared to stock parts. This upgrade improves your shock absorbers’ damping and heat dissipation. The market for high-end aftermarket dampers is expanding, with advanced semi-active shock absorbers now totaling 42 million units. Choosing the right components helps you achieve the best performance suspension and transforms how your shock absorbers handle every bump and turn.

How High-Flow Piston Technology Works

To understand the upgrade, you first need to know how a shock absorber piston works. This component is the heart of the damping system. It moves inside the shock body and controls how fluid passes between the compression and rebound chambers. This action is what creates damping force. High-flow designs manage this fluid exchange far more efficiently than stock parts, giving you a significant performance advantage.

Stock vs. High-Flow Piston Designs

A stock piston often uses a simple, stamped construction with basic porting. A high-flow piston, however, is a precisely machined component designed for maximum fluid movement. The design of these advanced pistons follows key principles of fluid dynamics.

- Hydraulic Damping: The piston converts your vehicle’s kinetic energy into heat by pushing fluid through its ports.

- Fluid Flow Dynamics: The piston’s movement creates pressure differences, forcing fluid through calibrated valves and generating resistance.

- Pressure Distribution: During compression, pressure builds below the piston, and during rebound, it builds above. High-flow designs manage these pressure changes smoothly.

The Impact on Damping and Control

A high-flow piston gives you more precise control over your vehicle’s handling. The design of the piston’s ports—their shape, size, and inlet smoothness—directly tunes the damping curve. For example, pistons with round-shaped ports deliver linear performance. This means adjustments create a consistent change in stiffness, making your shock absorbers easier to fine-tune. Smooth port inlets prevent oil flow disruption, which you feel as a less harsh ride. The entire system follows a fundamental rule of fluid dynamics.

The flow rate of fluid through the piston is described by the orifice flow equation: Q = Cd × A × √(2ΔP/ρ). This formula shows how the orifice area (A) and pressure differential (ΔP) directly control the flow rate (Q).

Better flow management allows your shock absorbers to react instantly to terrain changes, keeping your tires planted for superior grip and stability.

Reducing Cavitation and Harshness

Have you ever felt a sudden, harsh impact from your suspension on a rough road? You may have experienced cavitation. Cavitation is the formation of tiny air bubbles in the damping oil when fluid pressure drops too low. These bubbles collapse violently in high-pressure zones, creating shockwaves that cause a harsh feel and reduce damping consistency. High-flow pistons help prevent this. Their efficient design promotes smoother fluid transfer, which maintains more stable internal pressures. This reduces the chance of cavitation, ensuring your shock absorbers deliver consistent, predictable performance without the harshness.

Types of Performance Piston Upgrades

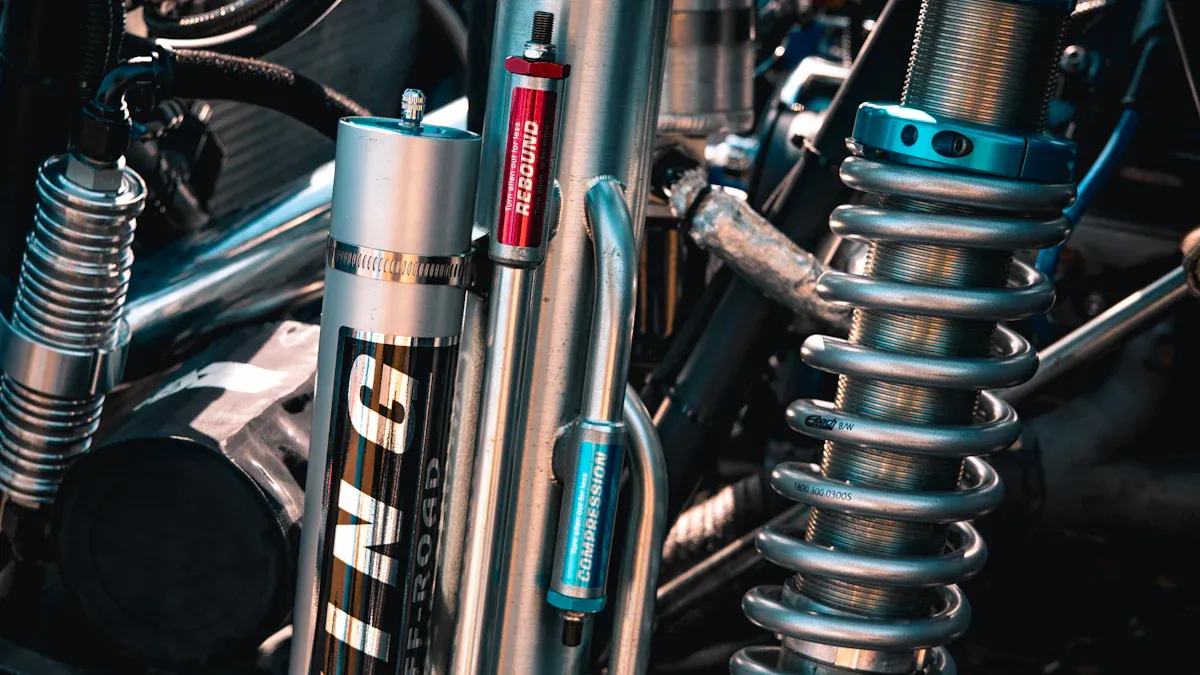

When you decide to upgrade, you will find several types of performance pistons available. Each design offers unique benefits for your vehicle’s suspension. Choosing the right one depends on your performance goals, from off-road racing to improved street comfort. Let’s explore the most common upgrades: multi-port billet pistons, bypass-enabled pistons, and tunable pistons.

Multi-Port and Billet Pistons

The most accessible and significant upgrade from a stock component is a multi-port billet shock absorber piston. Unlike factory pistons, which are often made from weaker stamped metal, billet pistons are precision-machined from a solid block of high-grade aluminum. This manufacturing process creates an incredibly strong and durable part that resists bending or failing under extreme stress.

These pistons feature an advanced multi-port design. The ports are the channels that allow fluid to pass through. High-flow designs optimize the size, shape, and number of these ports to improve fluid dynamics significantly.

- Superior Strength: Billet construction handles higher pressures and impacts without deforming.

- Increased Flow: Optimized ports allow more oil to move smoothly, reducing the risk of cavitation and harshness.

- Tuning Consistency: The precise design provides a predictable and linear response to valving adjustments, making your shock absorbers easier to fine-tune.

Upgrading to a billet piston gives you a stronger foundation for building a high-performance suspension system.

Bypass-Enabled Pistons

Bypass technology gives you position-sensitive damping. This means your shock absorbers can provide different levels of resistance depending on where the piston is in its travel. This feature is a game-changer for vehicles that encounter a wide range of terrain, especially in off-road applications. The system creates distinct damping zones for a truly customized ride.

- Ride Zone: This is the middle range of shock travel where you spend most of your time. The damping is softer here to absorb small bumps and deliver a plush, comfortable ride.

- End Zone (Bottom-out): As the suspension nears full compression, the damping becomes much stiffer. This increased resistance prevents the harsh clunk of bottoming out on large impacts.

- Top-out Zone: When the suspension extends fully, damping also increases. This helps control body roll during cornering and prevents the shock from topping out on rebound.

Bypass shocks achieve this by using external tubes or internal passages that allow oil to flow around the main piston. As the piston moves and covers these bypass ports, the fluid is forced through the main piston’s valving, increasing the damping force. There are two primary designs for this technology.

| Feature | Internal Bypass | External Bypass |

|---|---|---|

| Design | Bypass passages are built inside the main shock body. | External tubes are mounted alongside the shock body. |

| Adjustability | Limited external adjustability; major changes require disassembly. | Highly adjustable externally, allowing you to fine-tune damping zones. |

| Heat Dissipation | Less efficient due to the internal design. | More efficient due to the larger surface area of external tubes. |

| Packaging | More compact and fits in tighter spaces. | Larger and may require more room for mounting. |

| Application | Common in OEM performance packages and applications where space is limited. | Preferred for high-performance off-road racing where precise tuning is critical. |

Tunable and Adjustable Pistons

For the ultimate level of control, you can choose tunable and adjustable pistons. These advanced components allow you to alter the damping characteristics without disassembling the shock. This technology often relies on innovative internal mechanisms that change how fluid flows through the piston on the fly.

One cutting-edge method involves using a mixture of special porous materials. By adjusting the composition of these materials, you can change the pressure required to force fluid through them. This directly modifies the shock’s damping performance.

Advanced Damping Explained Some tunable systems can create a “double-step” damping effect. This allows your shock absorbers to automatically switch between soft and firm characteristics. You get soft damping at high speeds for comfort over small bumps and firm damping at low speeds for better handling and control.

This level of adjustability lets you dial in the perfect suspension feel for any condition, whether you are preparing for a track day, heading off-road, or simply cruising on the highway. It represents the peak of modern suspension tuning capability.

Choosing the Right Shock Absorber Piston

Selecting the perfect piston upgrade transforms your vehicle’s performance. The right choice depends on your driving needs, your vehicle, and your existing suspension components. A thoughtful decision ensures you get the control, comfort, and durability you expect from your investment. This guide will help you navigate the options and make an informed choice.

Matching Pistons to Your Driving Style

Your driving style is the most important factor in choosing a piston. A piston designed for off-road racing will feel harsh on the street, while a street-focused piston will not survive aggressive off-road use. You must match the piston’s flow characteristics to your primary application.

For example, off-road racing often uses progressive damping. This setup feels soft during low-speed piston movements, allowing your suspension to soak up small bumps for a smooth ride. As you hit larger obstacles and piston speed increases, the damping becomes much stiffer to prevent bottoming out.

In contrast, track and performance street driving benefit from digressive damping. This style provides firm resistance at low piston speeds, which gives you a stable and connected feel during cornering and braking. As piston speeds increase over big bumps or curbs, the damping force tapers off to prevent the car from becoming unsettled.

Consider these common scenarios:

- Off-Road and Trail Riding: You need a piston that supports progressive damping. Look for designs that can handle high fluid flow to absorb major impacts without harshness. This is crucial for your coilover suspension to articulate properly over uneven terrain.

- Track and Performance Street: You will want a piston that works well with a digressive damping curve. This gives you sharp handling and control. A quality billet piston provides the consistency needed for predictable cornering.

- Daily Driving and Towing: You should look for a balanced, often linear, design. This provides a predictable response across various conditions, improving comfort and stability without being overly aggressive.

A Pre-Purchase Compatibility Checklist

Before you buy a new shock absorber piston, you must confirm it will fit your equipment. Mismatched parts can lead to poor performance or even damage your shock absorbers. Use this checklist to ensure compatibility.

- Verify Your Shock Model: Identify the exact brand and model of your shock absorbers or coilover suspension. Pistons are not universal.

- Measure Piston and Bore Size: You need to know the inner diameter of your shock body (the bore) and the diameter of the shock shaft. The new piston must match these dimensions precisely.

- Check Valving Compatibility: Ensure the new piston is compatible with the type of valving shims you plan to use.

- Consult with Experts: Getting professional advice is one of the smartest moves you can make. An experienced technician can help you select the perfect components for your goals.

Many expert shops will help you tailor components to your specific needs. As one tuning expert notes, they often swap pistons to get even better results and may offer this service for free when you purchase shocks through them. It’s a “no-brainer” to use their expertise.

Considering Brand and Shock Model

Leading suspension brands like Fox, King, and Icon build their shock absorbers with distinct design philosophies. This directly influences which piston upgrades will work best. Fox and King, for instance, typically use linear pistons that deliver a consistent and predictable feel. Icon, on the other hand, often uses digressive pistons to create a firmer low-speed response for their OE applications.

Understanding how pistons influence performance is key.

- Piston Design and Oil Flow: The number and shape of ports on a piston determine how much oil can flow through it. More ports generally allow higher oil volume, which directly impacts how responsive your coilover suspension feels.

- Impact on Shock Valving: The piston’s flow characteristics are the foundation of your shock’s valving. More oil flow typically creates softer valving for a smoother ride, while restricted flow results in firmer valving for greater control.

- Tuning Goals: The ultimate goal is to balance comfort and performance. Choosing a piston with the right flow characteristics allows you or a tuner to customize the valving for your ideal coilover suspension setup.

Different brands engineer their pistons to achieve specific ride qualities.

| Brand | Piston Design | Ride Characteristics |

|---|---|---|

| FOX | Linear | Delivers a steady, predictable ride. This makes it versatile for mixed road conditions and provides excellent stability. |

| KING | Linear | Creates a balanced feel across both rough and smooth terrain. These are often re-valved for specific performance needs. |

Ultimately, choosing the right piston means matching its design to both your driving style and the specific brand of shock absorbers on your vehicle.

Installation and Tuning Fundamentals

Upgrading your piston is a hands-on job that requires precision. Proper installation and tuning are essential to get the performance you want. This process ensures your shock absorbers work correctly and safely.

Essential Steps for Piston Installation

You must handle installation with care to avoid damaging your components. Safety is your first priority. Before you begin, always follow the manufacturer’s guidelines for your specific shock absorbers.

Safety First! ⚠️ Always release all pressure from pressurized shock absorbers before taking them apart. This prevents the sudden release of fluid or parts, which can cause serious injury.

You will need specialized tools for a successful installation. Using the right equipment prevents damage to the piston rod and internal seals.

- Pass-through sockets allow you to tighten the top nut without spinning the piston rod.

- Shaft clamps securely hold the damper shaft during assembly.

- Bullet tools help you guide the shaft through the sealhead without tearing the seals.

How to Approach Initial Tuning

Once your new piston is installed, you can begin the shock tuning process. A systematic approach will help you find the perfect settings. You should only make small, incremental changes to understand their effect.

- Find a consistent test track. Use a familiar loop of road or trail to feel how each adjustment changes performance.

- Adjust one setting at a time. This helps you isolate the impact of each change.

- Keep a detailed logbook. Record your initial settings and every adjustment you make. This allows you to easily return to a previous setup if needed.

The Role of Shock Oil Viscosity

The oil inside your shock is just as important as the piston. Shock oil viscosity measures the oil’s resistance to flow. This is measured in a unit called Centistokes (cSt). Think of it like this: water has a low viscosity (about 1 cSt), while honey has a very high viscosity (around 1,000 cSt).

Choosing the right oil is critical.

- Low-viscosity (thinner) oil flows easily. It is ideal for fast-moving components and can provide a softer feel.

- High-viscosity (thicker) oil resists flow. It is used for heavily loaded parts and creates firmer damping.

The viscosity of your shock oil works with your piston’s flow rate to create the final damping force.

Upgrading your shock absorber piston is a key step toward the best performance suspension. This enhancement delivers tangible gains, improving control and even contributing to quieter vehicle operation. Your specific driving goals—whether for track, trail, or street—will determine the ideal piston choice. To unlock your vehicle’s potential, you need components from a team committed to quality.

Expert Tip: Rely on engineering teams with certifications like IATF 16949. This standard ensures a focus on defect prevention and continuous improvement, giving you confidence in your performance suspension parts.

Partnering with certified experts helps you select the perfect upgrade to achieve the best performance suspension.

FAQ

How much does a high-flow piston upgrade cost?

The price for a high-flow piston varies. Costs depend on the brand, material, and complexity of the design. Billet aluminum pistons for popular shock models are a common starting point. You can find options to fit different budgets, from accessible upgrades to premium race-spec components.

Can I install a new piston myself?

You can perform the installation with the correct tools, like shaft clamps and a seal bullet. However, working with high-pressure shocks is dangerous. For safety and best results, you should consider seeking help from a professional technician who has the proper equipment and experience.

Is a high-flow piston worth it for a daily driver?

Yes, an upgrade offers clear benefits for daily driving. A high-flow piston improves ride comfort by reducing harshness over bumps. It also enhances vehicle control during braking and cornering. This upgrade provides a more stable and predictable driving experience on the street.

How can I ensure I’m buying a quality piston?

You should choose pistons from manufacturers with proven quality systems.

Look for suppliers who hold certifications like IATF 16949. This automotive quality standard ensures the parts are made with a focus on defect prevention and consistent performance, giving you confidence in your upgrade.