When you select a coil of spring for engineering projects, you’re making critical decisions that impact performance and longevity. The right coil of spring type enhances efficiency, keeps equipment operating smoothly, and extends its lifespan. Recent studies reveal that a well-designed coil of spring can significantly improve the functionality and durability of renewable energy systems, especially in challenging environments. By choosing the best materials for your coil of spring, you can prevent fatigue failure and ensure dependable shock absorption. Understanding how different coil of spring designs work empowers you to build stronger, more efficient machines across a wide range of industries.

Coil Spring Types and Their Engineering Significance

What Is a Coil Spring?

You see coil springs in many machines and devices around you. A coil spring is a piece of metal wire shaped into a spiral or helix. Engineers often call it a “helical spring” when they want to be precise. In everyday language and in most industries, people use the term “coil spring.” The name can change depending on the field, but the basic idea stays the same. You use coil springs to store energy, absorb shock, and control movement. These springs help keep cars stable, doors working smoothly, and even medical devices safe.

Tip: When you choose a coil of spring for your project, you need to know how it works and what it can do. This helps you solve problems and improve your designs.

Main Types of Coil Springs in Modern Engineering

You will find several coil spring types in engineering. Each type has a special job. You can see how they work and what they do in the table below:

| Type of Coil Spring | Function |

|---|---|

| Compression Springs | Store and release energy when compressed, absorbing shock and maintaining force. |

| Tension Springs | Resist pulling forces, absorb and store energy as they extend, return components to position. |

| Torsion Springs | Apply torque, store energy during twisting, return to the original position. |

You use these types of coil springs in many industries. Compression coil springs help absorb shock in car suspensions and keep machines running smoothly. Tension springs, also called extension springs, stretch when you pull them and snap back when you let go. Torsion springs twist to store energy and help things like garage doors or clothespins work.

Let’s look at the mechanical properties that make each type unique:

| Spring Type | Key Mechanical Properties |

|---|---|

| Compression Spring | Helical shape, many materials, wire diameter affects strength, outer diameter impacts fit, coil count influences deflection, spring rate measures stiffness, durable against fatigue. |

| Extension Spring | Tightly wound helical form, material choice based on use, wire diameter affects load, outer diameter impacts fit, coil count influences extension, spring rate measures stiffness, durable against fatigue. |

| Torsion Spring | Helical configuration, material choice based on use, wire diameter affects torque, leg length and shape customizable, outer diameter impacts fit, coil count influences torque, spring rate measures torque per degree, durable against fatigue. |

You need to pick the right material for your coil spring. Here are some common choices:

- Music Wire: Strong and affordable, best for dry places. Handles up to 250ºF (121ºC).

- Stainless Steel: Handles higher temperatures (up to 550ºF / 288ºC), resists rust, good for medical uses.

- Chrome Silicon: Stronger than music wire and stainless steel, works up to 475ºF (246ºC), not good for humid places.

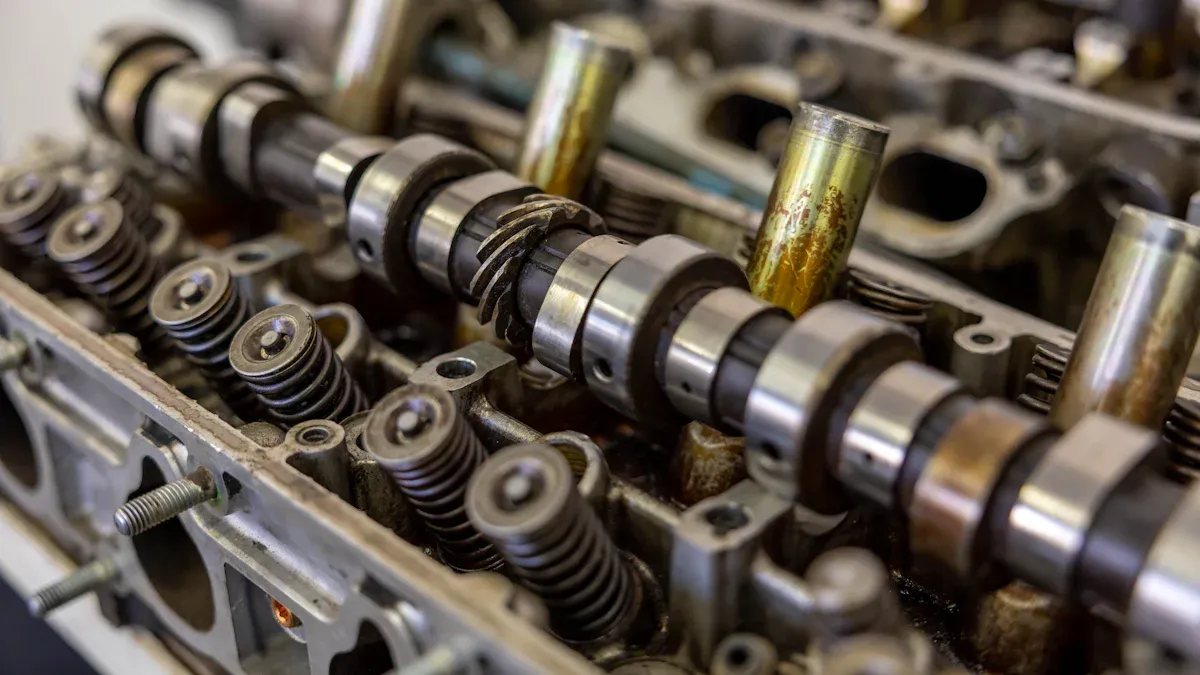

You see coil springs in many fields. Compression coil springs are used in car suspension systems, seat mechanisms, clutch assemblies, brake systems, engine valves, and vibration dampening. Torsion springs help in garage door mechanisms, hinges, mouse traps, watches, and vehicle suspension systems. Wave springs are found in aerospace systems, automotive components, bearing preload applications, electronic devices, and medical devices.

When you understand the types of coil springs and their properties, you can choose the best coil of spring for your engineering needs. This helps you build safer, stronger, and more reliable machines.

Compression Coil Spring Applications in Engineering

Working Principle of Compression Springs

When you use a coil of spring in your project, you rely on its ability to store and release energy. Compression coil springs work by following Hooke’s Law. This law says that the force needed to compress the spring matches the distance you push it. As you apply a load, the spring deflects and stores potential energy. When you remove the load, the spring returns to its original shape and releases the stored energy. This process helps with shock absorption and keeps your machines running smoothly.

- Deflection happens when you press down on the spring.

- The spring stores energy during compression.

- The energy stored can be calculated with the formula: U = k · δ² / 2, where k is the spring constant and δ is the deflection.

- When you let go, the spring releases energy and returns to its starting shape.

- The more you compress the spring, the more energy it can store.

You see this principle at work in many coil spring applications. The ability to absorb and release energy makes these springs vital in both simple and complex machines.

Engineering Uses and Performance Benefits

You find compression coil springs in almost every industry. These springs play a key role in agriculture, construction, aeronautical, petrochemical, transportation, and manufacturing. You also see them in materials handling, automotive, industrial equipment, mining, and precision tools. Even consumer products like mattresses, trampolines, and toys use coil springs.

- Compression coil springs provide the force needed for many mechanical systems.

- They absorb energy, which is critical for shock absorption in heavy-duty applications.

- Their reliability under repeated use ensures consistent performance.

- Testing for fatigue life helps you predict how long the spring will last.

- In automotive suspension systems and aerospace technology, these springs help create smoother rides and improve safety.

You depend on the right coil spring to boost performance and reliability. The applications of springs show how important they are for modern engineering. When you choose the correct coil spring, you make your machines safer and more efficient.

Extension Coil Spring Types and Their Uses

How Extension Springs Function

You use extension coil springs when you need a part that stretches and then pulls back to its original shape. These springs work by creating an opposing force when you pull on them. This force helps control movement in many machines. When you stretch the spring, it stores energy. When you let go, the spring returns to its starting length and releases that energy.

- Extension coil springs absorb, store, and resist opposing forces.

- They help control motion and keep parts in place.

- You find them in machines that need smooth, controlled movement.

You often see these springs in heavy-duty applications. For example, they help dampen vibrations in electrical engineering and provide the pulling force needed in industrial presses and stamping tools. The design of each coil of spring allows it to handle repeated stretching and returning, which is important for reliable performance.

Key Applications in Modern Engineering

You find extension springs in many industries. Their ability to stretch and return makes them useful in both simple and complex systems. The table below shows where you might see these coil springs and what they do:

| Industry | Applications |

|---|---|

| Automotive | Seat recliners, trunk and hood latches, door handles |

| Aerospace | Retractable landing gear, cabin components |

| Medical Devices | Surgical instruments, hospital beds |

| Industrial Manufacturing | Manufacturing machinery, assembly line systems |

| Agriculture | Tensioning belts and cables in farming equipment |

| Construction | Cranes for lifting and tensioning |

| Renewable Energy | Wind turbines for cable tension |

| Marine | Securing hatches and doors on ships and boats |

| Oil and Gas | Securing equipment, similar to marine uses |

You also see extension springs in garage doors, trampolines, washing machines, and even baby carriages. In each case, the spring provides the force needed for smooth operation. In automotive systems, these springs improve ride comfort and safety. In aerospace, they help control surfaces and landing gear. Industrial machinery uses them in levers and actuators for efficient movement.

Recent advances in coil spring technology have led to lighter, stronger designs. Manufacturers now use high-strength alloys and corrosion-resistant materials. This means you get longer-lasting springs that work well in tough environments. You can also find custom coil springs for electric and hybrid vehicles, which help improve energy efficiency.

Note: When you choose the right extension coil springs, you make your machines safer, more reliable, and ready for modern challenges.

Torsion Coil Spring Solutions for Modern Challenges

Torsion Spring Mechanism and Operation

You use torsion coil springs when you need to control rotational movement. These springs work differently from compression coil springs and extension springs. Instead of compressing or stretching, torsion coil springs store energy by twisting around an axis. When you apply force, the spring resists by twisting, and it returns to its original position when you release the force.

Here is a table that shows how different types of springs store energy:

| Type of Spring | Energy Storage Mechanism |

|---|---|

| Torsion Spring | Stores energy by twisting around an axis |

| Compression Spring | Stores energy through axial compression |

| Extension Spring | Stores energy through linear extension |

You often see torsion coil springs in devices that need rotational force. For example, you find them in clothespins, door hinges, and many mechanical parts. These springs resist twisting or rotational forces and help control movement in both directions. When you use a torsion spring, you get smooth and controlled motion for your project.

Engineering Applications and Advantages

You find torsion coil springs in many modern engineering solutions. These springs work well in heavy-duty applications because they can handle repeated twisting without losing strength. You see them in automotive systems, industrial machinery, and even in garage doors.

Here are some main advantages of using torsion coil springs:

- You get high efficiency in space utilization.

- These springs offer durability and long-term reliability.

- You can design them for custom applications.

- They give you precise control over torque.

- Torsion coil springs provide torque in both clockwise and counterclockwise directions.

- They work well for complex rotational movements.

- You get excellent bidirectional force distribution.

- The spring assembly contains the energy, which means less risk of injury or property damage if a failure happens.

- Many engineers prefer these springs for residential uses because of their safety features.

When you choose a coil spring for your project, you should consider torsion coil springs for tasks that need rotational force and safety. These springs help you build reliable machines and systems that last.

Material and Design Considerations for Coil Springs

Selecting Materials for Performance and Durability

When you choose spring materials, you shape how your springs perform in real-world conditions. The right material helps your coil spring last longer, handle more stress, and resist corrosion. You often see engineers select materials based on the environment and the job the spring must do. For high-stress engineering, you might use silicon chrome or chrome vanadium wire because they offer high strength and excellent fatigue resistance. Stainless steel and titanium alloys work well when you need both strength and corrosion resistance, especially in harsh or wet environments.

Here is a table showing common materials and their properties:

| Material Type | Properties |

|---|---|

| Silicon Chrome | High strength, suitable for extreme loads |

| Chrome Vanadium Wire | Excellent fatigue resistance, used in high-stress applications |

| Steel | Versatile, strong, and widely used |

| Copper | Good conductivity, used for electrical properties |

| Titanium Alloys | Lightweight, high strength, corrosion-resistant |

You also find music wire, Inconel, and other specialty alloys in demanding applications. The choice of material affects how well your springs resist fatigue and corrosion. For example, stainless steel and titanium alloys provide excellent durability under high-velocity impacts.

Impact of Coil Spring Design on Engineering Outcomes

The design of your coil springs changes how they work in machines. You control the load capacity and flexibility by adjusting the wire diameter, the number of active coils, and the spring rate. A larger wire diameter increases load capacity but reduces how much the spring can compress. More active coils make the spring more flexible but lower its load capacity.

| Parameter | Description |

|---|---|

| Wire Diameter (WD) | A larger wire diameter generally increases load capacity but can reduce available deflection. |

| Active Coils (AC) | The number of active coils influences the spring’s flexibility and load capacity. |

| Spring Rate (K) | Indicates the amount of force required to compress the spring by a specific distance. |

You see these design choices in both linear springs and torsion coil springs. When you design extension coil springs, you must balance strength and stretch. Careful design ensures your springs meet the needs of your application.

Innovations in Coil Spring Engineering

You benefit from new technologies and materials in coil spring engineering. Smart springs now have sensors that monitor real-time conditions, which helps you track performance and prevent failures. Engineers use lightweight alloys and composites to improve the strength-to-weight ratio. Automation in manufacturing, like robots for coiling and inspection, increases quality and speed. 3D printing lets you create complex spring shapes that were not possible before.

- Smart technologies: Embedded sensors for real-time monitoring

- Lightweight alloys and composites: Better strength-to-weight ratios

- Automation: Robots improve production speed and consistency

- 3D printing: Enables complex and custom spring designs

These innovations help you achieve better handling, longer durability, and more options for customization in your coil springs.

Real-World Coil Spring Examples in Industry

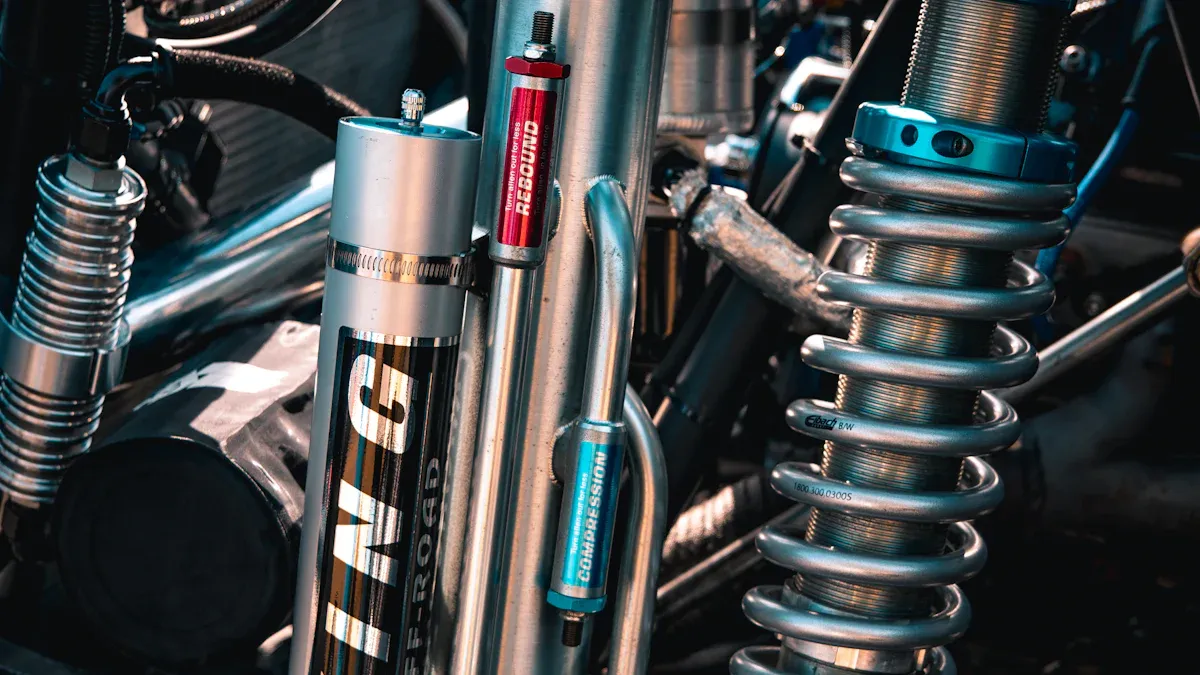

Automotive and Auto Parts Applications

You see springs everywhere in the automotive world. When you drive, coil springs help keep your ride smooth and safe. These springs absorb energy from bumps and dips in the road. They control how your car moves up and down, making sure the tires stay in contact with the ground. This helps you stay stable and comfortable. The table below shows how coil springs improve safety and comfort in vehicles:

| Contribution to Vehicle Safety and Comfort | Description |

|---|---|

| Energy Absorption | Coil springs absorb and store energy from road disturbances, reducing the impact felt by passengers. |

| Control of Vertical Motion | They control the vertical motion of the wheels, maintaining tire contact with the road for stability. |

| Reduction of Road Shock | Properly designed springs minimize road shock transmitted to passengers, enhancing ride comfort. |

| Support for Vehicle Weight | They support the vehicle’s weight, ensuring balanced suspension performance. |

| Smoothing Out Disturbances | Springs compress and rebound to smooth out disturbances, providing a comfortable ride. |

You rely on coil springs in shock absorbers, seat mechanisms, and suspension systems. These springs also help with handling and braking, making your car safer.

Construction and Infrastructure Solutions

You find springs in many construction projects. Coil springs serve as anchors in new buildings and reinforce old foundations. They support sidewalks and minimize movement. You see springs in safety release valves that control pipelines. These springs release steady pressure to prevent damage. In bridges and railway buffers, coil springs offer support and flexibility. They act as vibration dampers, absorbing shocks from trains. Springs resist corrosion, so they work well in all kinds of weather.

- Coil springs serve as anchors in new construction and reinforce existing foundations.

- They provide support and minimize movement in sidewalks.

- Commonly used in safety release valves to control pipeline operations.

- They release a steady amount of pressure to prevent damage and system failures.

- In bridges and railway buffers, they offer mechanical support and flexibility.

- Coil springs act as vibration dampers, absorbing shocks from train operations.

- They are designed to resist corrosion, ensuring consistent performance in various weather conditions.

You also see coil springs in industrial machinery. These springs absorb and dissipate energy from shocks, which helps keep equipment stable when handling heavy loads. Heavy-duty coil springs withstand tough conditions and improve handling. High-quality materials and coatings extend the life of springs, so your equipment stays reliable.

Electronics and Precision Engineering

You use springs in many electronic devices. Coil springs give you tactile feedback in keyboards and buttons. They make camera shutters work smoothly. In wearable technology, springs help fasten straps while allowing flexibility. You see springs in battery compartments, where they ensure electrical connections. Advanced alloy springs in smartphones improve responsiveness and strength. Micro-electromechanical systems (MEMS) use tiny springs in chips, which enable new sensors and actuators.

- Coil springs provide tactile feedback in devices, enhancing user interaction.

- They ensure reliable operation in various applications, such as camera shutters and laptop keystrokes.

- In wearable technology, coil springs contribute to secure fastening while allowing flexibility.

- Small springs have been refined over decades, paralleling advancements in electronic devices.

- Springs are crucial for mechanical functions and ensuring electrical connectivity in devices like battery compartments.

- Advanced alloy springs in smartphones enhance mechanical responsiveness and structural integrity.

- Micro-electromechanical systems (MEMS) integrate microscopic springs into chips, enabling new sensors and actuators.

You see coil spring technology driving miniaturization and precision in modern electronics. Springs play a key role in mechanical applications, making devices more durable and user-friendly.

Choosing the right coil spring type helps you meet your engineering goals. You must look at several factors, such as environment, design, durability, and cost. The table below shows what you should consider:

| Factor | Description |

|---|---|

| Environment | Think about temperature and corrosion resistance. |

| Design and Performance | Match the spring’s size and strength to your needs. |

| Durability and Fatigue | Pick materials that last through many cycles. |

| Corrosion Resistance | Use materials that resist rust and damage. |

| Cost | Balance quality with your budget. |

| Availability | Make sure you can get the materials on time. |

When you understand spring types and materials, you can create better solutions. You need to check wire thickness, tension, and force for each project:

| Key Consideration | Description |

|---|---|

| Spring Wire Thickness | Affects strength and how much the spring can handle. |

| Spring Tension Requirements | Helps the spring work as needed. |

| Spring Force Calculations | Makes sure the spring will not fail under pressure. |

As engineering changes, you will see new trends in coil spring use. The table below highlights what to expect:

| Sector | Projected Trends |

|---|---|

| Automotive | Lighter, stronger springs for better cars. |

| Industrial Machinery | More precise and durable springs for smart machines. |

| Aerospace | Springs that last longer and resist corrosion. |

| Agriculture | Tough springs for advanced farming tools. |

| Construction | Strong springs for modern building equipment. |

| Others | Tiny, custom springs for electronics and medical devices. |

By learning about coil spring types, materials, and design, you can build safer, more efficient machines for any industry.

FAQ

What is the main difference between compression and extension coil springs?

Compression springs push back when you press them. Extension springs pull back when you stretch them. You use compression springs to absorb shock. You use extension springs to return parts to their original position after pulling.

How do you choose the right material for a coil spring?

You look at the environment and the job the spring must do. For wet places, stainless steel works best. For heavy loads, silicon chrome or chrome vanadium gives you strength. Always match the material to your needs.

Why do engineers use torsion coil springs in machines?

Torsion coil springs store energy by twisting. You use them when you need to control rotation, like in door hinges or clothespins. These springs help parts move smoothly and return to their starting position after turning.

Can coil springs be custom-made for special projects?

Yes, you can order custom coil springs. You choose the size, shape, and material. Custom springs help you solve unique engineering problems and fit your exact needs. Many companies offer this service for both small and large orders.

How do coil springs improve safety in vehicles?

Coil springs absorb bumps and shocks from the road. They keep your tires on the ground and help control your car’s movement. This makes your ride smoother and safer, especially when you drive over rough surfaces or take sharp turns.