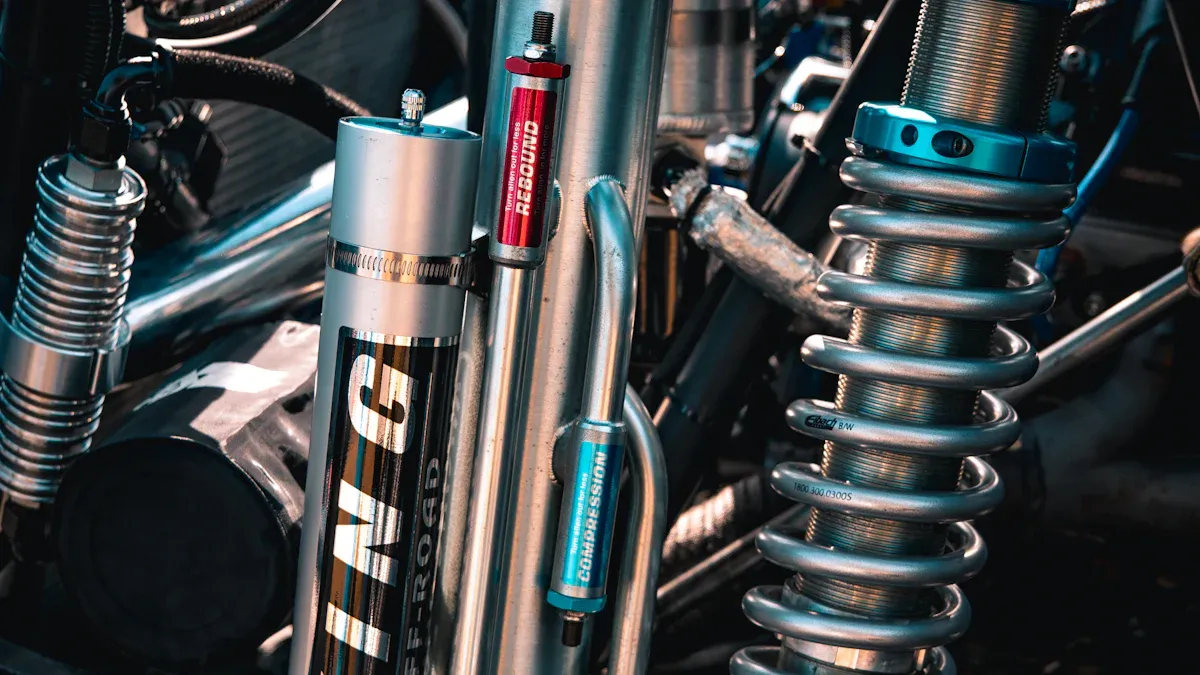

You can think of shock valving shims as the gatekeepers inside your vehicle’s suspension. These [“shock valving shims”] precisely control oil flow within the shock absorbers, turning bumps and dips into a smooth, controlled ride.

💡 Did You Know? Your vehicle’s comfort and handling depend heavily on this technology. It is a key part of a growing industry, as the global shock absorber market is projected to reach USD 23.26 billion by 2032, showing just how vital these components are for modern vehicles.

The Mechanics of Shock Valving Shims

To understand how these small metal discs transform your ride, you need to look at the two primary movements of your suspension: compression and rebound. Shims control the oil flow during both phases. This control creates the damping force that keeps your vehicle stable and comfortable.

Controlling Compression for Impact Absorption

The compression stroke happens when your wheel hits a bump and the shock absorber shortens. Your shock’s piston moves, forcing hydraulic oil through small passages. The shims act as a flexible gate over these passages. This resistance to oil flow is what absorbs the impact energy. Without it, your suspension would bottom out harshly on every bump.

The magic of modern high performance shocks lies in how they provide tailored damping at all speeds. This is achieved through the careful arrangement of shims in a stack.

- Low-Speed Compression: When you drive over small, gentle bumps, the shaft moves slowly. This creates low oil pressure. Only the largest, most flexible shims near the piston bend slightly. This allows a controlled amount of oil to pass, giving you a soft, comfortable response.

- High-Speed Compression: When you hit a large pothole or land a jump, the shaft moves very quickly. This generates immense oil pressure. The pressure forces the initial shims to flex much further, pressing against the smaller, stiffer shims in the stack. This creates a much stronger damping force, preventing the shock from bottoming out and helping you maintain control.

This progressive system ensures your ride is smooth during normal driving but firm when you need to handle major impacts. The entire process of managing compression is governed by fundamental fluid dynamics.

🔬 The Science Behind the Force The damping force you feel is a direct result of pressure. As the piston forces oil toward the shims, pressure builds up on the valve face. This pressure difference creates the force that slows the piston’s movement. The oil’s properties, like its thickness (viscosity), and physical laws, like Bernoulli’s Principle, determine exactly how much force is generated as the fluid accelerates through the valve openings.

Managing Rebound for Tire Traction

Rebound is the opposite of compression. It is the phase where the shock extends back to its normal length after being compressed. The primary job of rebound damping is to control the speed at which the wheel returns to the ground. This is critical for maintaining tire traction.

If a shock extends too quickly, your tire can bounce off the road surface. If it extends too slowly, the suspension can “pack down” over a series of bumps, unable to recover between hits. The [“shock valving shims”] on the rebound side of the piston precisely regulate this movement.

This control is especially important for vehicle stability during cornering. Rebound damping on the inside shocks works with compression damping on the outside shocks to resist body roll. This manages how quickly weight transfers from one side of the car to the other, directly affecting how your tires are loaded. Proper rebound settings give you a predictable cornering feel and prevent sudden traction loss.

An incorrect rebound setting can cause serious issues, most notably wheel hop.

- Excessive rebound damping can cause the shock to “pack,” where it can’t extend fast enough over rapid bumps.

- This packing leads to a cycle where the tire loses and regains grip, creating a chattering or hopping sensation.

- Often, reducing rebound while increasing compression damping can help push the tire back into the ground, increasing grip and making wheel hop less likely.

Ultimately, the shims controlling rebound are a key tuning tool for balancing your chassis and ensuring your tires stay firmly planted on the road.

How Shim Stacks Dictate Performance Shock Valving

A single shim cannot provide the dynamic response your vehicle needs. Instead, tuners arrange multiple shims into a carefully engineered shim stack. This stack sits on the shock’s piston. The specific arrangement of these shims—their order, diameter, and thickness—is the secret behind custom-tuned performance shock valving. The shim stack works as a team to control oil flow across a huge range of shaft speeds.

Stacks vs. Shaft Speed

The speed of the shock’s shaft directly impacts how the shim stack behaves. Suspension experts use a tool called a force-velocity graph to see this relationship. This graph plots damping force (how stiff the shock feels) against the shaft’s speed.

- Low-Speed Damping: This occurs at shaft speeds below approximately 1 inch per second (about 25 mm/s). It controls your vehicle’s body roll during cornering and its response to gentle bumps.

- High-Speed Damping: This happens at speeds above 1 inch per second. It manages the impacts from potholes, curbs, or landing jumps.

A basic shim stack might produce a linear curve. This means the damping force increases at a steady rate with speed. However, many high performance shocks use a digressive curve. A digressive setup provides more damping force at low speeds and then “blows off” or provides less relative force at very high speeds. This gives you firm control during cornering without feeling harsh over big, sudden hits.

🔧 How Tuners Shape the Curve Tuners can change the shape of the damping curve from digressive to more linear by modifying the

shim stack. For example, adding a “crossover” shim (a smaller shim between larger ones) allows the first few shims to bend more easily at low speeds. This softens the initial response before the rest of the stack engages for high-speed hits. This level of tuning is what separates good suspension from great suspension.

The Effect of Shim Diameter and Thickness

The two most important properties of any individual shim are its diameter and its thickness. These physical traits determine the shim’s stiffness and how it contributes to the overall feel of the shim stack. Changing even one shim can have a noticeable effect on your ride.

Diameter changes the leverage on the shim. A larger diameter shim is easier to bend because the oil pressure has more surface area to push against.

Thickness has an even bigger impact on stiffness. The stiffness of a shim increases exponentially with its thickness. A small increase in thickness makes the shim much, much harder to bend.

You can think of their effects like this:

| Change to Shim | Effect on Stiffness | Typical Use Case |

|---|---|---|

| Increase Diameter | Softer | To reduce damping force for a plusher ride. |

| Decrease Diameter | Stiffer | To increase damping force for more control. |

| Increase Thickness | Much Stiffer | To make a significant increase in damping. |

| Decrease Thickness | Much Softer | To make a significant decrease in damping. |

Expert tuners use a precise combination of diameters and thicknesses to build a progressive shim stack. This allows them to fine-tune how the shock valving shims respond to every possible input, giving you a vehicle that feels both comfortable and capable. Dyno testing, which produces force-velocity graphs showing force in Newtons versus speed in meters per second, validates these tuning choices.

The Art of Tuning Shims for Your Vehicle

Fine-tuning your suspension is both a science and an art. The goal of shock tuning is to match your vehicle’s damping characteristics to your specific needs. This process involves choosing between different valving philosophies. Your decisions here will define how your vehicle feels and performs on the road or trail.

Stiff vs. Soft Valving Setups

One of the most fundamental choices in shock tuning is deciding between a stiff or soft setup. This choice creates a trade-off between comfort and control.

Soft Valving: A softer setup allows your suspension to move more freely. This is excellent for comfort, especially over small, frequent bumps. The shock absorbs these imperfections easily, keeping the tire in constant contact with the road. This gives you a smoother, more predictable ride. You will find it difficult to even notice minor road flaws.

Stiff Valving: A stiffer setup provides more resistance to suspension movement. This can reduce body roll during cornering and prevent the chassis from bouncing after large bumps. However, a setup that is too stiff can feel harsh. It may transmit every road imperfection directly to you, making the ride tiring and ‘darty’.

The right balance depends entirely on your goals. A daily driver benefits from a softer setup, while a dedicated track car often requires a stiffer one.

Linear vs. Digressive Valving

Beyond just stiff or soft, the way your damping force builds up is critical. This is where linear and digressive valving come into play. This aspect of shock tuning is what truly unlocks the potential of high performance shocks.

Linear Valving creates a damping force that increases at a steady, predictable rate with shock speed. On a dyno graph, this appears as a straight line. It provides a very consistent feel across all conditions. Achieving a truly linear curve requires a precise combination of shock valving shims, valve design, and oil viscosity.

Digressive Valving offers a more dynamic response. It provides firm damping at low shaft speeds, which helps control body roll and gives you a sporty, connected feel during cornering. Then, as you hit a large bump at high speed, the damping force tapers off. This allows the suspension to absorb the impact without feeling harsh, keeping the tires on the ground. This characteristic makes it a top choice for aggressive driving disciplines like autocross, where sharp handling and chassis control are essential.

The Role of Quality and Precision in Shims

The performance of your shock absorbers depends directly on the quality of the shims inside. A shim is not just a simple washer. It is a high-tech spring that must flex millions of times without failing. The material it is made from and the precision of its manufacturing are what separate average suspension from truly great high performance shocks.

Why Material and Heat Treatment Matter

You need shims made from the right material to withstand the intense forces inside a shock. The choice of steel alloy determines a shim’s durability and resistance to fatigue. Different materials offer unique benefits for specific conditions.

| Material Type | Durability Level | Common Use Case |

|---|---|---|

| High-Carbon Steel | Very High | The standard for most shock valving stacks. |

| Stainless Steel | High | Ideal for wet or muddy off-road conditions. |

| Alloy Steel | Highest | Reserved for extreme, professional racing. |

After selecting the material, heat treatment is the next critical step. This process strengthens the steel and makes it more durable. Proper heat treatment creates a stable internal structure in the metal. This allows the shim to bend repeatedly without permanently deforming or breaking. It optimizes the balance of strength and flexibility, ensuring your shims provide consistent damping performance for the life of the shock.

The Impact of Precision Manufacturing

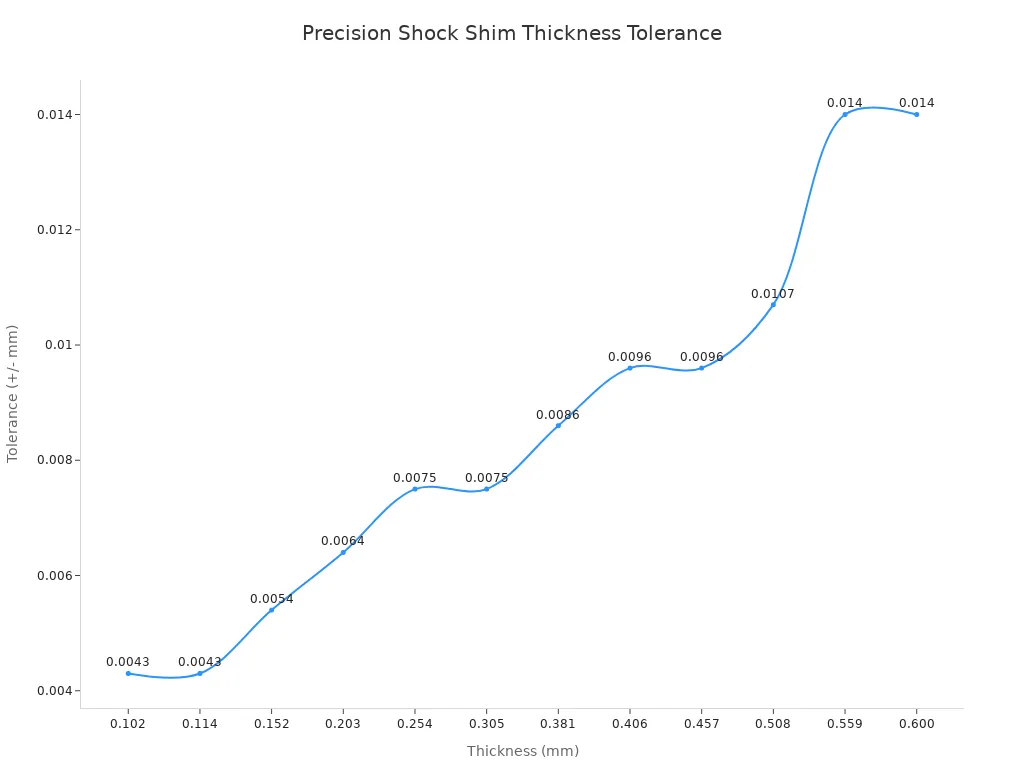

In shock tuning, tiny changes make a big difference. This is why precision manufacturing is essential. Shims must be made to incredibly tight specifications because even a small error in thickness or flatness can completely alter your suspension’s behavior.

Manufacturers use several advanced processes to achieve this level of accuracy:

- Stamping: This method uses a die to quickly press shims out of a metal sheet. It is very efficient for making large quantities of a single shim size.

- Laser Cutting: A CNC laser cutter uses a focused beam of light to cut shims. This process is highly precise and can create complex shapes for custom tuning.

- Waterjet Cutting: This technique uses a high-pressure stream of water to cut the metal. It is versatile and effective for many shim designs.

These methods produce shims with extremely tight tolerances. The allowable error in thickness is often as small as ±0.005 mm. Flatness is also tightly controlled to ensure the shims stack perfectly and do not rock, which would cause inconsistent performance. The chart below shows how these tight tolerances relate to shim thickness.

This commitment to precision ensures that every shim performs exactly as the tuner intended, giving you a predictable and reliable ride.

Shock valving shims are the critical element inside high performance shocks. They turn raw force into refined control. Understanding how they work empowers your approach to shock tuning. You can adjust your suspension for the perfect balance of comfort and capability. This knowledge is key to successful shock tuning.

💡 Your Next Step With this foundation, you are ready to begin your own shock tuning journey. You can now confidently create a setup that matches your vehicle to your exact driving style, whether on the trail or the road.

FAQ

What is the main job of a shock valving shim?

A shock valving shim acts like a gate inside your shock absorber. It controls the flow of oil. This action creates damping force, which absorbs bumps and keeps your tires on the ground. Your ride comfort and vehicle handling depend directly on these shims.

Can I tune my own shocks by changing the shims?

Yes, you can tune your own shocks. Changing the order, thickness, or diameter of the shims in the shim stack alters the damping. This process, called re-valving, allows you to customize your suspension for a softer or stiffer feel, matching your specific driving needs.

Why is shim quality so important?

High-quality shims ensure consistent performance. They are made from durable steel and manufactured to precise thicknesses.

This precision guarantees that your shocks perform predictably. Poor quality shims can bend or break, leading to a loss of damping and an unsafe, unpredictable ride.

What is the difference between compression and rebound damping?

Compression and rebound are two distinct actions.

- Compression controls the shock as it shortens to absorb a bump.

- Rebound controls the shock as it extends back to its normal length.

Properly balancing both is key to achieving great handling and a smooth ride.