Your motorcycle’s suspension is a complex system where a tiny part, the motorcycle suspension shims, plays a huge role in its performance. These small, thin washers control the oil flow inside your suspension’s shock and forks, which in turn manages the damping. The global motorcycle suspension system market was valued at USD 860.68 million in 2024 and is expected to grow, highlighting just how vital a good suspension is. Proper damping ensures you get better handling and a smoother ride.

The shim acts like a flexible valve for both compression and rebound damping. Compression damping controls the suspension as it absorbs a bump, while rebound damping manages the speed at which the suspension returns to its original position. Having the right motorcycle suspension shims is key to achieving perfect handling.

Choosing the correct shim allows you to fine-tune the suspension. You can adjust the damping to match your specific weight and riding style. This level of tuning significantly improves your motorcycle’s handling and shock absorption, giving you more control and confidence on any road.

Decoding Shim Dimensions: Diameter and Thickness

Understanding shim dimensions is the first step to tuning your suspension. Every shim has an inside diameter (ID), an outside diameter (OD), and a thickness. These three measurements work together. They control the oil flow for both compression and rebound damping. You must choose the correct dimensions for your specific shock or fork model.

Inside and Outside Diameter

The inside diameter must match the post on your suspension piston. The outside diameter must fit within the piston housing. These sizes are not flexible. You must use the correct diameters for your suspension. Some engines use a shim-over-bucket design. Others use a shim-under-bucket system. The diameter is critical for both systems to function correctly. A wrong diameter can cause the shim to bind or fail. This leads to poor rebound control and unpredictable suspension behavior. A proper fit ensures the shim flexes correctly, which is vital for consistent rebound and compression damping. The correct diameter helps your suspension manage rebound effectively.

Shim Thickness and Damping Force

Shim thickness directly controls the stiffness of your damping. A thicker shim is harder to bend. It creates more resistance to oil flow. This results in stronger damping for both compression and rebound. A thinner shim bends more easily. It allows more oil to pass through. This creates softer damping. The change in damping force is significant. Even a tiny change in thickness can transform how your suspension feels.

Pro Tip: A change of just 0.05mm in shim thickness can have a noticeable effect on your motorcycle’s handling and shock absorption. Always make small, incremental adjustments.

Engineers use specific formulas to calculate the stiffness of a shim stack. These calculations can create graphs. The graphs show the force generated by each shim for compression and rebound. This visualizes how thickness affects the overall damping force of the shock. Your motorcycle suspension shims are the key to this adjustment. The right thickness fine-tunes your suspension for optimal rebound and damping performance. A shim-under-bucket system relies on this principle for precise valve control.

Choosing the Right Material for Your Motorcycle Suspension Shims

The material of your motorcycle suspension shims directly impacts your suspension performance and durability. You have a few options, but two materials dominate the market: spring steel and titanium. Your choice depends on your riding needs and budget.

Spring Steel: The Industry Standard

You will find that most suspension systems use spring steel shims. This material is the industry standard for good reason. Spring steel provides incredible durability and consistent performance. It has excellent fatigue strength, which allows it to flex millions of times without cracking or losing its shape. This resilience is vital for consistent damping over the life of your suspension.

Engineers choose specific grades of steel, like 1075 blue temper spring steel, for their high tensile strength. This strength ensures the shim can handle the intense forces inside your suspension. Whether your bike uses a shim-over-bucket or a shim-under-bucket design, spring steel delivers reliable damping control.

Did You Know? High-carbon spring steel is engineered to withstand millions of stress cycles. This makes it the perfect material for a suspension shim that must constantly flex to control oil flow and provide smooth damping.

Different steel alloys offer varying levels of strength. You can see how they compare below.

| Grade | Tensile Strength (MPa) |

|---|---|

| 1075 (EN 10132-2021) | 610 |

| 1095 (EN 10132-2021) | 640 |

| 60Si2Mn (diameter=10mm) | 1274 |

| Music Wire (SWP-B, diameter=1.0mm) | 2260~2450 |

For the vast majority of riders, high-quality spring steel offers the best balance of performance, longevity, and cost for any suspension tuning.

Titanium Shims: The Racing Edge

You might consider titanium shims if you are a competitive racer seeking every possible advantage. The main benefit of titanium is its low weight. A titanium shim is significantly lighter than a steel one. This reduces the suspension’s unsprung mass, allowing it to react to bumps more quickly. The result is improved tire contact and more responsive damping.

However, this performance comes at a cost. Titanium is much more expensive than spring steel. It can also be more brittle, making it less forgiving in some situations. For this reason, you will typically only find titanium shims in professional racing applications where budgets are large and small performance gains can mean the difference between winning and losing.

The Role of the Shim Stack in Damping

You now know about shim dimensions and materials. Let’s explore how they work together in a shim stack. The stack is the heart of your suspension’s damping control. It dictates how your bike handles both small bumps and big hits. Understanding the stack is crucial for tuning your compression and rebound damping.

What is a Shim Stack?

A shim stack is a carefully arranged group of shims. You will find it on the piston inside your fork or rear shock. This stack flexes to control oil flow. The arrangement of the shims determines the damping characteristics of your suspension. When your suspension moves, oil pushes against the stack. The shims bend, creating a gap for the oil to pass through. The stiffness of the stack controls how much force is needed to open this gap. This action creates your compression and rebound damping.

Your motorcycle suspension shims work in both directions. One stack controls compression, and another stack manages rebound. The configuration of each stack directly affects your ride quality. A well-designed stack provides precise control over your suspension’s behavior. This is true for both shim-over-bucket and shim-under-bucket systems.

Face Shims and Low-Speed Damping

Face shims are the first shims in the stack that the oil pushes against. They have the biggest impact on low-speed damping. Low-speed damping affects how your suspension reacts to gentle movements, like body roll during cornering or smooth road undulations. The diameter of the face shim is very important. A larger diameter shim is more flexible and controls low-speed compression, giving you a smoother ride.

The stack design also determines when your suspension transitions from low-speed to high-speed damping. A special shim, called a crossover shim, helps manage this transition. Placing a smaller diameter crossover shim between larger ones can soften the initial compression damping. This makes the transition to high-speed damping happen sooner.

Tuning for Your Feel 📝 You can change the face shims to get the ride you want. Your choices directly impact the low-speed compression and rebound damping.

For a plush, soft feel:

- Use thinner shims in the main stack.

- Add a bleed shim to soften the very first part of the suspension movement.

- Use a smaller diameter clamp shim to let the stack flex more easily.

For a firm, responsive feel:

- Use thicker shims to increase overall stiffness and damping.

- Add a face shim to significantly increase compression damping.

- Use a larger diameter clamp shim to make the stack firmer.

The Pyramid Stack and High-Speed Damping

High-speed damping manages how your suspension handles sharp, sudden impacts like hitting a pothole or landing a jump. Many shim stacks are arranged in a pyramid shape. This means the shims get progressively smaller in diameter as they move away from the piston face. This is called a tapered stack.

The taper of the stack influences the bend radius of the face shims. This change in bend radius alters the fluid flow area when the suspension moves quickly. By adjusting the stack’s taper, a tuner can change the damping forces at high suspension speeds. This allows for fine-tuning of the high-speed compression and rebound.

It is a common myth that the high-speed part of the stack only controls high-speed damping. The entire shim stack works as a system. While changing the pyramid’s stiffness does change the shock’s overall damping force, it does not change the basic shape of the damping curve. A professional tuner can adjust a tapered, straight, or stiff stack to achieve the same damping performance. The key is understanding how each shim contributes to the overall feel of the rebound and compression in your suspension. This knowledge is vital for both shim-under-bucket and shim-over-bucket designs. The goal is to create predictable rebound damping and controlled compression for a confident ride.

How to Tune Your Motorcycle Suspension for Different Riding Styles

Your motorcycle suspension needs are unique to how you ride. A street rider wants comfort, while a racer needs firm control. The right shim stack setup makes all the difference. Proper suspension tuning transforms your bike’s behavior. It allows you to tailor the damping to your specific style, giving you the best possible handling and confidence.

Street and Touring Setups

For street riding and long-distance touring, your main goals are comfort and stability. You want a suspension that absorbs bumps and road imperfections smoothly. This creates a plush ride that reduces fatigue. Your shim stack should provide soft low-speed compression damping. This allows the wheels to move easily over small bumps.

At the same time, you need enough rebound damping to keep the bike from feeling bouncy or uncontrolled. The rebound must be quick enough to keep the tire on the road but slow enough to prevent a pogo-stick effect.

Street Comfort Checklist 📝

- Goal: A smooth, stable ride that absorbs road chatter.

- Compression: Softer low-speed compression for a plush feel over small bumps.

- Rebound: Controlled rebound damping to prevent bouncing and maintain tire contact.

- Result: Improved comfort and predictable handling for daily commutes and long tours.

A tuner achieves this by using thinner face shims or a smaller clamp shim. This lets the stack flex more easily at low suspension speeds. The result is a motorcycle suspension that feels compliant and connected to the road. It gives you confident handling without the harshness.

Track and Racing Setups

On the racetrack, your priorities shift from comfort to maximum control. You need a firm suspension that provides excellent feedback and support during aggressive riding. The suspension must manage hard braking, rapid acceleration, and high cornering forces. This prevents excessive chassis movement, which can upset the bike’s balance.

To achieve this, your shim stacks need to be much stiffer. This involves several advanced suspension tuning techniques:

- Adding Face Shims: This is a straightforward way to increase overall stiffness. However, it can sometimes make low-speed compression too harsh.

- Changing the Stack Taper: Shortening the pyramid stack increases high-speed stiffness. This adjustment helps prevent the shock from bottoming out on sharp bumps or dips in the track.

- Adjusting the Crossover: A tuner can change the crossover shim’s diameter or thickness. This fine-tunes the transition from low-speed to high-speed damping, giving you precise control over the suspension feel.

- Modifying the Clamp Shim: Using a larger clamp shim makes the entire stack stiffer. This provides more support and changes the overall damping curve.

Professional tuners often use software like ReStackor to model these changes. This allows them to see how each adjustment affects the damping force profile. They can then build a stack that provides firm compression damping to hold the bike’s line in a corner and precise rebound damping for quick direction changes. The right setup gives you the confidence to push your bike to its limits.

Off-Road and MX Setups

Off-road and motocross riding present the most extreme challenges for a suspension system. You need a setup that can handle a huge variety of impacts, from small rocks to massive jumps. The key is finding a balance between plushness for traction and stiffness for big hits.

For technical enduro and trail riding, your suspension needs a soft initial stroke. This allows the wheel to track over rocks and roots, maximizing grip. Custom valving services often modify shim stacks to prevent rock deflection, where the front tire bounces off square-edged bumps. Kits like the Krooztune Flow Adjuster for WP forks allow you to make external adjustments. You can shift from a firm motocross feel to a plush enduro setting for rocky terrain. This provides excellent compliance for slow, technical sections and stability for faster parts of the trail.

For motocross, the focus is on handling large jumps and absorbing hard landings. Preventing the shock and forks from bottoming out is critical. This requires significant high-speed compression damping. Tuners achieve this by building a progressive damping curve.

- The stack is soft at the beginning of the travel for small bumps.

- It becomes much stiffer deeper in the stroke to absorb jump landings.

This is often done with a two-stage stack that uses a crossover shim. The first stage provides the initial plushness, while the second, stiffer stage engages to handle the big impacts. The rebound damping is equally important. It must be fast enough to keep the wheels on the ground through braking bumps but slow enough to prevent the rear shock from kicking back after a big compression. This careful balance of compression and rebound gives you superior handling and control on any off-road surface.

Key Considerations Before You Change a Shim

You are ready to fine-tune your motorcycle’s handling. Before you open up your shock or forks, you need to consider a few key points. Proper preparation and knowing your limits are crucial parts of the suspension setting process. This approach ensures your changes improve the ride instead of creating new problems.

Starting with a Baseline

You must start with a known baseline. This is your current suspension setting. Write down every detail before you make a single adjustment. This includes your clicker settings for compression and rebound, spring preload, and the existing shim stack if you know it. Make only one small change at a time. For example, change one shim in the compression stack, then test the suspension. This method helps you understand the direct effect of your adjustment on the damping and overall handling.

Pro Tip: Keep a Detailed Log 📝 Record every change you make and how it feels on the road or trail. Note the impact on both compression and rebound damping. This log will become your personal suspension troubleshoot guide.

The Importance of Quality Control

The quality of your motorcycle suspension shims is not negotiable. A low-quality shim can ruin your suspension performance. Even a tiny flaw can change the damping force by as much as 15%. This inconsistency creates unpredictable handling and defeats the purpose of tuning. High-quality shims are manufactured to incredibly tight tolerances, often following standards like ISO 2768 for general geometry.

You should only use shims from a reputable supplier who checks for straightness, rough edges, and correct thickness. The precision required is extreme, as shown in the tolerance chart below.

| Thickness (mm) | Tolerance (mm) |

|---|---|

| 0.102 | ±.00508 |

| 0.127 | ±.00635 |

| 0.254 | ±.0127 |

| 0.381 | ±.01905 |

| 0.508 | ±.0254 |

Using a precisely made shim ensures your shock provides consistent compression damping and rebound damping. This is vital for both standard and shim-over-bucket systems.

When to Consult a Professional Tuner

Sometimes, a problem is too complex for a DIY fix. You should consult a professional tuner if you face persistent suspension damping problems. If your handling is inconsistent or you cannot tell if an issue is from the suspension or your riding, an expert can help. They have the tools and experience to diagnose difficult issues with your rear shock and forks. A professional service can build a custom stack to perfect your rebound damping and compression. While it costs money, it can save you time and frustration.

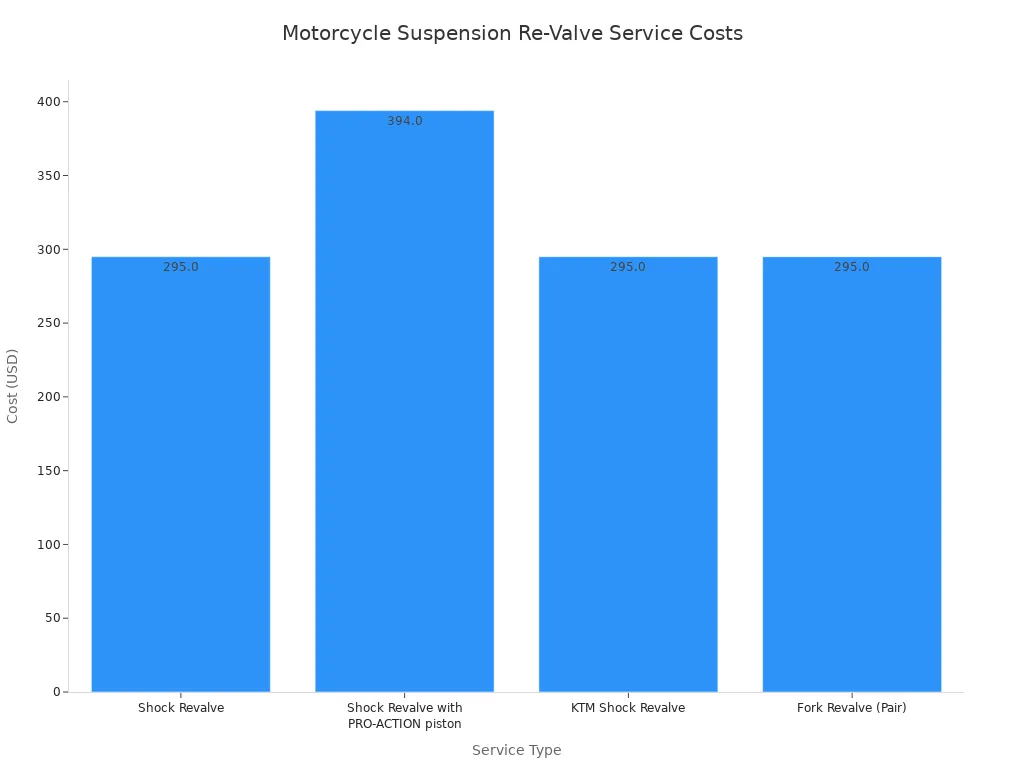

A professional re-valve is the best solution for complex rebound and damping issues. It ensures your suspension is perfectly matched to you.

You now know that choosing the right motorcycle suspension shims is a balance. Your suspension needs the correct shim to create perfect damping. For most riders, high-quality spring steel offers reliable damping for the shock.

Final Tuning Advice 📝 Always make one small change at a time. This helps you feel the effect on compression and rebound. A professional can fix complex shock rebound and compression damping issues. They perfect your shock’s rebound and compression damping. This improves your suspension’s rebound and compression damping. Proper rebound damping gives you control. Your rebound will feel perfect.

FAQ

What is the main job of a suspension shim?

You will find that shims control the flow of oil inside your suspension. This action creates resistance, which is known as damping. The right shims give you the correct amount of damping for a smooth and controlled ride.

Can I reuse old suspension shims?

You should avoid reusing old shims. They can bend or lose their shape over time. A damaged shim will provide inconsistent damping. Always use new, high-quality shims for predictable performance and reliable damping.

How do I know if my damping is wrong?

You can feel incorrect damping while you ride. A bouncy feeling after bumps points to poor rebound damping. A harsh ride over small bumps suggests your compression damping is too stiff. Both issues show a need for adjustment.

What is the difference between compression and rebound damping?

Compression damping controls the suspension as it absorbs a bump. Rebound damping manages the speed at which the suspension returns to its original position. Both types of damping are critical for proper handling and control.