When choosing a hydraulic chrome bar for your cylinder, you have many options to consider. Some cylinders operate under heavy loads or in challenging environments, making durability essential. You need a hydraulic chrome bar that resists wear and delivers long-lasting performance. Induction hardened hydraulic chrome bars provide excellent resistance to damage and can withstand significant stress. By selecting the right hydraulic chrome bar, you ensure your hydraulic cylinders deliver superior performance, reliability, and strength when it matters most.

What Makes an Induction Hardened Hydraulic Chrome Bar Unique?

Definition and Core Features of Hydraulic Chrome Bar

When you look for a chrome rod for hydraulic cylinders, you want strength, smoothness, and reliability. A hydraulic chrome bar starts as a high-quality steel rod. Manufacturers grind and polish the surface to a precise finish. They then apply a layer of chrome plating. This chrome layer gives the rod a shiny look and helps it resist corrosion and wear.

Induction hardened hydraulic chrome rods stand out because they go through extra steps. The steel core stays tough and flexible. The surface becomes much harder. This combination means the rod can handle heavy loads and sudden impacts. You get a chrome rod for hydraulic cylinders that lasts longer and works better in tough jobs.

Induction Hardening and Chrome Plating Explained

Induction hardening uses a special process to change the surface of the steel rod. You pass the rod through a coil that creates a strong magnetic field. This field heats the surface quickly. Right after heating, the rod gets cooled fast with water or oil. This step changes the microstructure of the surface into martensite, which is very hard. The hardened layer usually goes 0.030 to 0.120 inches deep. The core stays softer and more flexible. This makes induction hardened hydraulic chrome rods both tough and resistant to cracks.

You get a rod with a hard shell and a strong core. The surface can reach up to 58 HRC in hardness. This means your chrome rod for hydraulic cylinders can resist scratches, dents, and bending. The induction process also makes the rod more uniform, so you get predictable results every time.

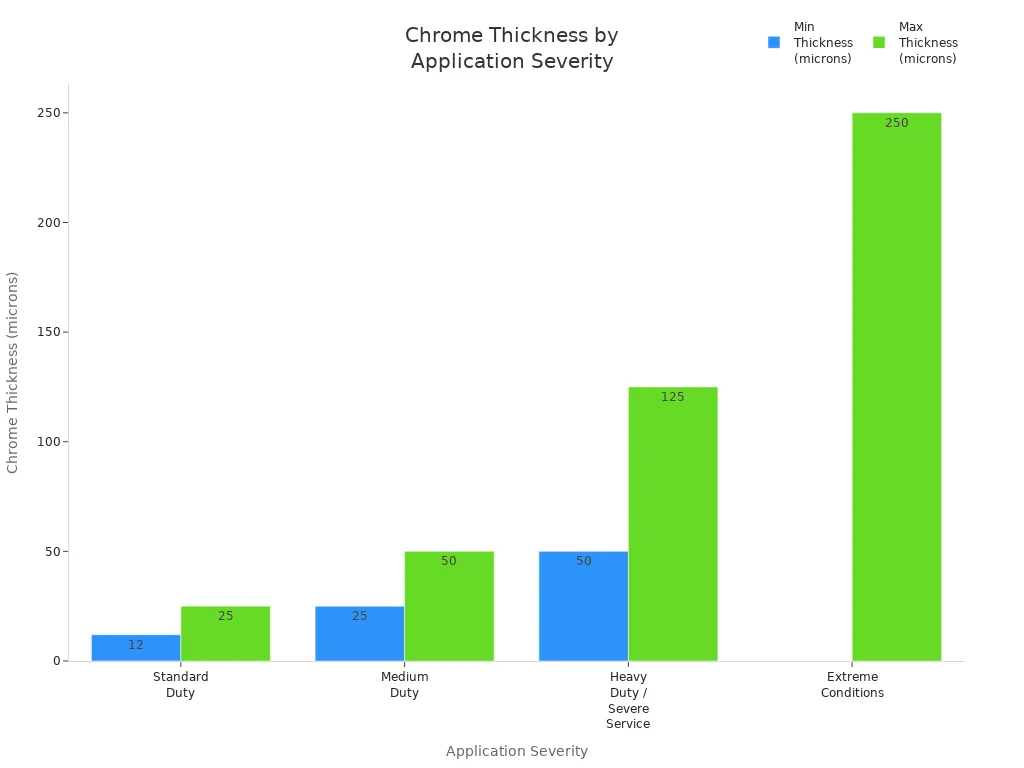

After induction hardening, the rod gets chrome plated. The thickness of the chrome layer depends on how tough the job is. Here is a table that shows typical chrome thickness for different uses:

| Application Severity | Typical Chrome Thickness (inches) | Typical Chrome Thickness (microns) | Industry Standards Referenced |

|---|---|---|---|

| Standard Duty | 0.0005 – 0.001 | 12 – 25 | ISO 4525, ASTM B177, DIN EN 12540, NF A91-101 |

| Medium Duty | 0.001 – 0.002 | 25 – 50 | Same as above |

| Heavy Duty / Severe Service | 0.002 – 0.005 | 50 – 125 | Same as above |

| Extreme Conditions | Up to 0.010 | Up to 250 | Same as above |

Thicker chrome layers protect induction hardened hydraulic chrome rods in harsh settings, like marine or chemical plants. Industry standards make sure the chrome layer meets strict rules for hardness and quality. When you choose induction hardened hydraulic chrome rods, you get a product that meets these high standards and gives your hydraulic cylinder the best chance for a long, trouble-free life.

Key Benefits of Induction Hardened Hydraulic Chrome Rods

Superior Wear Resistance and Longer Service Life

You want your hydraulic cylinder to last as long as possible. Induction hardened hydraulic chrome rods give you high resistance to wear. The induction process creates a hardened surface that stands up to friction and contact. This hardened layer protects the chrome rod for hydraulic cylinders from scratches and dents. You get wear resistance that keeps your equipment running longer. The chrome plating adds another shield. It works with the induction hardened layer to stop damage from daily use. You see long-lasting performance because the rod does not wear out quickly. Many industries choose induction hardened hydraulic chrome rods for this reason. You can trust these rods to deliver durability and wear resistance in every cycle.

Enhanced Strength, Durability, and Buckling Resistance

Induction hardened hydraulic chrome rods offer improved load capacity. The induction process makes the outer layer very hard, while the core stays tough and flexible. This combination gives you strength and durability. You can use these rods in heavy-duty machines without worry. The hardened surface resists bending and buckling. You get durability and wear resistance even under high pressure. The rod keeps its shape and does not fail when you need it most. This means you can rely on chrome rods for hydraulic cylinders in demanding jobs. The durability and wear resistance from induction hardening help your equipment last longer and work better.

Improved Corrosion Protection for Harsh Environments

You may need your hydraulic cylinder to work in wet or dirty places. Induction hardened hydraulic chrome rods give you improved corrosion resistance. The chrome plating stops water and chemicals from reaching the steel. The induction hardened surface adds another layer of protection. You get corrosion resistance that stands up to salt, moisture, and harsh chemicals. This means your chrome rod for hydraulic cylinders will not rust or break down easily. The durability and wear resistance from induction hardening and chrome plating keep your equipment safe. You see durability and wear resistance even in the toughest environments. Many users pick induction hardened hydraulic chrome rods for their improved corrosion resistance and long-lasting performance.

Tip: Always choose induction hardened hydraulic chrome rods if you need durability, wear resistance, and corrosion resistance in your hydraulic cylinders.

Precision Manufacturing and Better Seal Performance

When you choose an induction hardened hydraulic chrome bar, you get a product made with precision. The manufacturing process uses induction to heat the surface of the steel rod. This step creates a hardened layer that gives the bar its strength and wear resistance. The induction process also helps control the shape and size of the bar. You can expect tolerances as tight as +/- 1/16 inch for custom cuts. If you need even more accuracy, you can request tighter tolerances. This level of precision ensures your hydraulic cylinder works smoothly.

The induction hardened surface gives you an improved surface finish. This smooth finish is important for seal performance. When the bar moves inside the cylinder, the seal must keep oil from leaking. A rough or uneven surface can damage the seal or cause leaks. The induction process, combined with chrome plating, creates a hard and smooth surface. This surface reduces friction and helps the seal last longer. You get better wear resistance and less chance of mechanical breakdown.

You want your hydraulic cylinder to deliver top performance. Induction hardened chrome bars help you achieve this goal. The hardened layer resists scratches and dents. The induction process keeps the core strong and flexible. This combination improves the overall performance of your equipment. You see less downtime and fewer repairs.

Note: Precision in manufacturing and a smooth, hardened surface both play a key role in seal performance. You get reliable operation and longer service life when you choose induction hardened hydraulic chrome bars.

A summary of the benefits includes:

- Consistent induction hardened layer for strength and wear resistance

- Tight manufacturing tolerances for proper fit and seal performance

- Improved surface finish for better seal life and reduced friction

- Enhanced performance and reliability in every cycle

You can trust induction hardened hydraulic chrome bars to deliver the performance you need, especially when seal efficiency and wear resistance matter most.

When to Choose Induction Hardened Hydraulic Chrome Bar

High Load and Dynamic Applications

You need a hydraulic chrome bar that can handle heavy loads and fast movements. Induction hardened bars work best in these situations. The induction process creates a hard surface on the bar. This surface resists dents and scratches. The core of the bar stays tough and flexible. You get a cylinder rod that does not bend or break easily.

When you use hydraulic cylinders in construction equipment, mining machines, or large presses, you see high forces at work. These machines lift, push, or pull heavy objects. The induction hardened layer gives the bar extra strength. You get better durability and reliability. The bar keeps its shape even when the load changes quickly. This means your equipment works safely and smoothly.

Tip: Choose induction hardened hydraulic chrome bars for machines that move fast or carry heavy weights. You will see better performance and longer life from your hydraulic cylinders.

Abrasive, Corrosive, or Demanding Environments

Some jobs put your hydraulic chrome bar in tough places. Dust, sand, water, and chemicals can damage regular rods. Induction hardened bars stand up to these harsh conditions. The induction process makes the surface very hard. This hard layer protects the bar from scratches caused by dirt or grit.

The chrome plating adds another shield. It gives the bar strong corrosion resistance. You can use these bars in marine, chemical, or outdoor settings. The induction hardened surface and chrome layer work together. They stop rust and wear, even when the cylinder faces mud, salt, or chemicals.

If you use chrome rods for hydraulic cylinders in factories, farms, or ships, you need this extra protection. The induction hardened bar keeps working, even when the environment is rough. You get long-lasting performance and less downtime.

- Key benefits in demanding environments:

- High abrasion resistance from the induction hardened layer

- Strong corrosion resistance from chrome plating

- Reliable performance in wet, dirty, or chemical-filled areas

Requirements for Longer Service Life and Reduced Maintenance

You want your equipment to last. Induction hardened hydraulic chrome bars help you reach this goal. The induction process gives the bar a hard shell. This shell fights off wear and damage. The core stays strong and flexible. You get a cylinder rod that lasts longer.

When you use induction hardened bars, you spend less time and money on repairs. The hard surface means seals last longer. You see fewer leaks and less oil loss. The bar keeps its smooth finish, so the cylinder works well for a long time.

Many industries choose induction hardened hydraulic chrome bars for their longer service life. You get more hours of use from each cylinder. You also see better durability and reliability. Your equipment stays on the job, not in the repair shop.

Note: If you want less maintenance and more uptime, pick induction hardened hydraulic chrome bars. You will see better performance and a longer life for your hydraulic cylinders.

Cost vs. Performance Considerations

When you select a hydraulic chrome bar, you want to get the best value for your money. You need to think about both the cost and the performance. Induction hardened hydraulic chrome bars often cost more than standard rods. However, you should look at what you get for that extra investment.

You pay more for induction hardened bars because the manufacturing process uses advanced technology. The induction process heats the surface of the rod quickly and then cools it fast. This step creates a hardened layer that protects the rod from wear and damage. The chrome plating adds another layer of defense. You get a rod that lasts longer and works better in tough jobs.

Let’s break down the main points you should consider:

- Initial Cost: Induction hardened hydraulic chrome bars usually have a higher price tag. The induction process and extra quality checks add to the cost.

- Service Life: You get a longer-lasting product. The hardened surface stands up to friction, impact, and corrosion. You replace rods less often.

- Maintenance Savings: You spend less on repairs and downtime. The induction hardened layer keeps the rod smooth and strong. Seals last longer, and you see fewer leaks.

- Performance in Demanding Jobs: If your equipment faces heavy loads or harsh environments, induction hardened bars give you better results. You avoid unexpected breakdowns.

- Total Cost of Ownership: Over time, the money you save on repairs and replacements can outweigh the higher initial cost.

Here is a simple table to help you compare:

| Feature | Standard Chrome Bar | Induction Hardened Chrome Bar |

|---|---|---|

| Initial Cost | Lower | Higher |

| Service Life | Shorter | Longer |

| Wear Resistance | Moderate | Excellent |

| Corrosion Resistance | Good | Superior |

| Maintenance Needs | More Frequent | Less Frequent |

| Best For | Light/Medium Duty | Heavy/Demanding Duty |

Note: If you use your hydraulic cylinders in light-duty applications, a standard chrome bar might work well. If you need high performance and long life, induction hardened bars are the better choice.

You should also think about the risks of using a rod that is not induction hardened. If your equipment fails, you might lose time and money. You may also face safety issues. Induction hardened hydraulic chrome bars help you avoid these problems. You get peace of mind knowing your equipment can handle tough jobs.

When you talk to your supplier, ask about the induction process and the thickness of the hardened layer. Make sure the bar meets the standards for your industry. You want a rod that matches your needs and gives you the best return on your investment.

Checklist for Selecting the Right Hydraulic Chrome Bar

Assessing Application Demands and Load Conditions

When you select a hydraulic chrome bar for your cylinder, you must look at the demands of your application. Each cylinder faces different forces and conditions. To make the best choice, check these important factors:

- Make sure the inner diameter dimension is accurate. This helps your cylinder fit well and prevents leaks.

- Check the straightness of the tube. A straight tube keeps your cylinder from wearing out early.

- Look at the inner diameter surface quality. A smooth surface reduces friction and helps seals last longer.

- Know the yield strength of the steel. This tells you how much load your cylinder can handle without bending.

- Confirm the approved working pressure rating. Your cylinder must work safely at the system’s pressure.

- Think about weldability. If you need to customize or repair your cylinder, good weldability makes the job easier.

- Inspect the outer surface quality. A clean, smooth surface protects against corrosion and helps with installation.

Tip: Always match the bar’s features to your cylinder’s real-world needs for the best reliability and performance.

Evaluating Environmental and Operational Factors

You should also consider where and how your cylinder will work. If your cylinder operates in wet, dirty, or chemical-filled places, choose a bar with strong corrosion resistance. Dust, sand, and grit can scratch the surface, so a hard, smooth finish is important. If your cylinder faces frequent movement or shock loads, pick a bar that can handle dynamic stress. Think about temperature swings, as extreme heat or cold can affect how your cylinder performs. By looking at these factors, you help your cylinder last longer and work better.

Balancing Budget, Performance, and Service Life

You want to get the most value from your investment. Start by comparing the initial cost of the chrome bar with the expected service life. A higher-quality bar may cost more, but it often gives you better performance and fewer repairs. Think about how much downtime costs if your cylinder fails. A bar that offers long service life and high reliability can save you money over time. Use a simple table to compare your options:

| Factor | Standard Bar | Induction Hardened Bar |

|---|---|---|

| Cost | Lower | Higher |

| Performance | Good | Excellent |

| Service Life | Shorter | Longer |

| Reliability | Moderate | High |

Choose the bar that fits your needs and helps your cylinder deliver strong, reliable performance every day.

Consulting with Hydraulic and Engineering Experts

When you choose a hydraulic chrome bar for your cylinder, you face many options. You might wonder which coating or material works best for your needs. This is where consulting with hydraulic and engineering experts makes a big difference. Experts bring years of experience and deep technical knowledge. They help you understand the strengths of different coatings, such as hard chrome plating, laser cladding, or ceramic plating. You learn which option fits your application best.

Experts look at your working environment. They ask about exposure to water, chemicals, or dust. They check if your hydraulic system uses special fluids. They also consider how long you want your cylinder to last and how much you plan to spend. With this information, they recommend the best coating or rod type. Their advice helps you get better wear resistance, stronger corrosion protection, and less friction. Your hydraulic cylinder works better and lasts longer.

You also benefit from expert support when you need to repair or refurbish a cylinder. Experts know which coatings can be restored and which need replacement. They guide you through the process, so you avoid costly mistakes.

Tip: Always share details about your application with the expert. The more they know, the better their advice.

Here is a simple checklist you can use when talking to an expert:

- Describe your working environment (wet, dusty, chemical exposure)

- Share the type of fluid used in your system

- Explain the load and movement your cylinder handles

- State your expected service life and maintenance goals

- Discuss your budget limits

By working with experts, you make smarter choices. You get a hydraulic chrome bar that matches your needs and delivers top performance. This step ensures your equipment stays reliable and efficient for years to come.

You should choose induction hardened hydraulic chrome bars when your hydraulic cylinders face heavy loads, high friction, or harsh environments. Matching the right bar to your application helps your equipment last longer and work better. Expert advice can make a big difference. Here is what you gain with expert-recommended bars:

| Feature | Benefit for You |

|---|---|

| Hard Surface | Resists wear and damage |

| Smooth Finish | Improves seal life and efficiency |

| Strong Core | Handles heavy loads and high pressure |

| Corrosion Protection | Lasts longer in tough environments |

Max’s technical team can help you select the best bar for your needs, ensuring reliable and efficient performance.

FAQ

What is the main difference between induction hardened and standard hydraulic chrome bars?

Induction hardened bars have a hard outer layer and a tough core. This makes them stronger and more resistant to wear than standard bars. You get better performance in heavy-duty or harsh environments.

How do I know if my application needs an induction hardened hydraulic chrome bar?

You should choose induction hardened bars if your cylinder faces high loads, frequent movement, or harsh conditions like dust, water, or chemicals. These bars last longer and need less maintenance in tough jobs.

Can induction hardened hydraulic chrome bars improve seal life?

Yes. The smooth, hard surface of these bars reduces friction and prevents scratches. Your seals last longer, and you see fewer leaks. This helps your hydraulic system run smoothly.

Are induction hardened hydraulic chrome bars cost-effective in the long run?

You may pay more at first, but you save money over time. These bars last longer, need fewer repairs, and reduce downtime. You get better value for your investment.