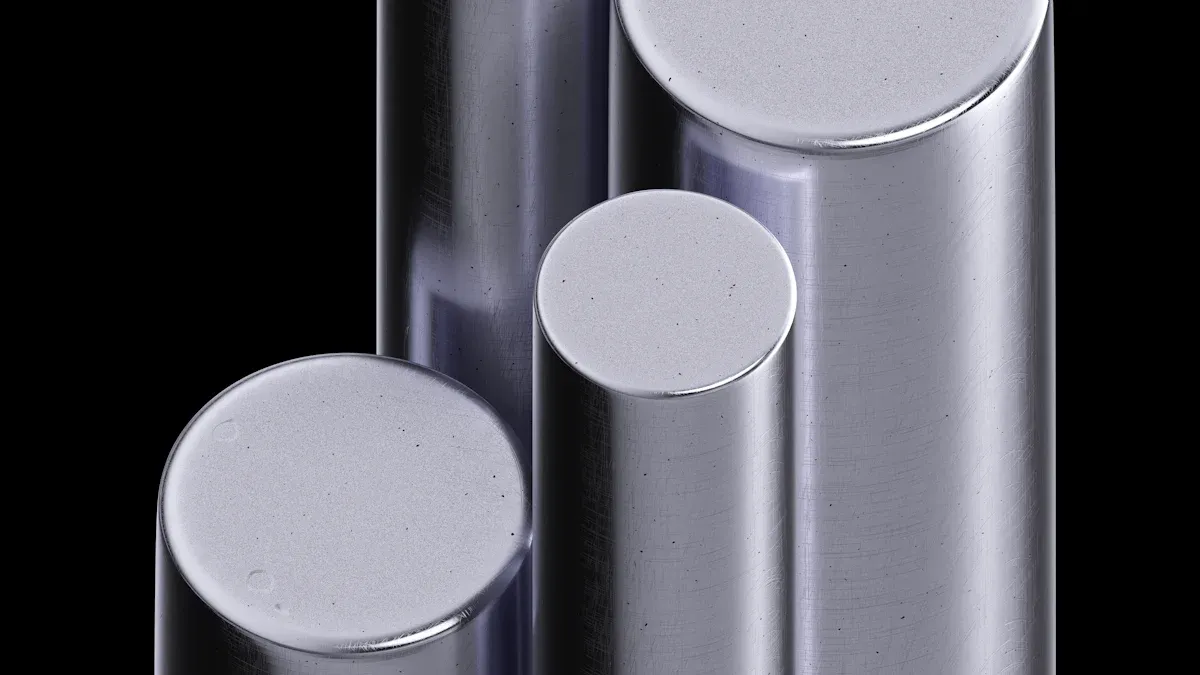

Plated rods play a vital role in modern industries by enhancing machinery performance and minimizing maintenance costs. Their exceptional combination of durability and corrosion resistance makes them essential in various industrial applications. These rods are commonly used in hydraulic systems, automotive components, and heavy machinery, where their smooth surface finish ensures precision and reliability. The global market for plated rods and tubes, valued at USD 6.5 billion in 2023, is projected to grow to USD 11.4 billion by 2033. This growth highlights their cost-effectiveness and the rising demand for high-strength materials that boost efficiency.

Understanding Chrome-Plated Rods

What Is a Plated Rod?

A plated rod is a specialized metal rod coated with a thin layer of material, such as chromium, to enhance its performance. In industrial applications, a plated rod often refers to a piston rod made from hard chrome-plated cold-finished steel. These rods play a critical role in hydraulic and pneumatic cylinders, where they transmit force from the piston to other machine components.

What sets plated rods apart is their exceptional corrosion resistance. This property prevents seal or piston rod failure, ensuring reliable operation even in harsh environments. By combining strength and precision, plated rods help maintain the efficiency of machinery across various industries.

Chrome Plating and Its Unique Properties

Chrome plating is a process that involves electroplating a thin layer of chromium onto a metal surface. This technique offers several benefits, making it a popular choice for enhancing the performance of plated rods.

| Key Concept | Description |

|---|---|

| Chrome Plating | A technique of electroplating a thin layer of chromium onto a metal object for various benefits. |

| Hard Chrome Plating | Used to reduce friction and improve durability, providing wear resistance and restoring dimensions. |

| Decorative Chrome Plating | Primarily for aesthetic purposes, enhancing the appearance of metal objects. |

The unique properties of chrome plating significantly improve rod performance. For instance:

- Wear resistance: Chrome plating enhances the rod’s ability to withstand high-stress applications.

- Lubrication retention: Micro-cracks in the chrome layer help retain lubricants, reducing friction and wear.

- Surface hardness: The hardened chrome surface increases the rod’s durability and lifespan.

To achieve these benefits, the plating process requires precise control over multiple parameters. Adjusting factors like temperature, current density, and plating time ensures the quality and durability of the chrome layer. This meticulous process results in rods that can handle demanding industrial tasks with ease.

Benefits of Chrome-Plated Rods in Industrial Settings

Durability and Wear Resistance

When it comes to industrial applications, durability is a key factor in ensuring machinery operates efficiently. Chrome-plated rods excel in this area by offering exceptional wear resistance. The hard chrome plating process increases the surface hardness of these rods to an impressive 66-70 HRC. This enhanced hardness allows them to withstand high levels of abrasion, making them ideal for demanding environments.

The wear resistance of chrome-plated rods also reduces friction during operation. For example, injection molds with hard chrome plating experience a 50% increase in lifespan due to reduced wear and low friction. Similarly, automotive piston rings benefit from improved wear resistance, which enhances engine efficiency and lowers emissions. These advantages make chrome-plated rods a reliable choice for industries that prioritize long-lasting performance.

Additionally, the low coefficient of friction in chrome plating helps components operate at lower temperatures. This feature minimizes heat-related damage, further extending the lifespan of the rods. By choosing chrome-plated rods, you can ensure your machinery remains operational for longer periods, reducing the need for frequent replacements.

Corrosion Resistance in Harsh Environments

Industrial settings often expose machinery to harsh conditions, including moisture, chemicals, and extreme temperatures. Chrome-plated rods provide excellent corrosion resistance, protecting against rust and degradation. This resistance ensures that the rods maintain their structural integrity even in challenging environments.

Advanced chrome plating techniques, such as the NiKrom process, enhance corrosion resistance by adding a nickel layer beneath the chrome. This method guarantees up to 1500 hours of protection in neutral salt spray tests, as per ISO 9227 NSS standards. Double-chromed bars, like those in the Cromax C series, achieve an AASS rating of 100 hours, offering superior protection against pitting and penetration.

These features make chrome-plated rods indispensable in industries like construction, automotive, and technology. Whether you’re working with hydraulic systems or heavy machinery, the corrosion resistance of these rods ensures reliable performance and reduced maintenance costs.

Cost-Effectiveness and Extended Lifespan

Investing in chrome-plated rods offers significant cost benefits over time. While the initial cost of chrome plating may seem higher, the extended lifespan and reduced maintenance expenses make it a cost-effective solution. For instance, hard chrome plating enhances the durability of components, allowing them to last up to five times longer than uncoated alternatives, as demonstrated by ASTM G65 wear testing.

The table below highlights the cost-effectiveness of chrome-plated rods compared to other materials:

| Material | Initial Cost | Maintenance Cost | Durability | Cost-Effectiveness |

|---|---|---|---|---|

| Hard Chrome | Moderate | Low | High | Excellent |

| Stainless Steel | High | Low | High | Excellent |

By reducing the frequency of replacements and minimizing downtime, chrome-plated rods help you save on operational costs. Their low-friction surface also improves machinery efficiency, leading to lower energy consumption. This combination of durability, performance, and cost savings makes chrome-plated rods a smart investment for any industrial setting.

Enhanced Precision and Smooth Surface Finish

Precision and surface finish are critical factors in industrial applications. Chrome plating significantly enhances both, making plated rods indispensable in industries where accuracy and smooth operation are paramount. When you use a plated rod with a chrome-plated finish, you benefit from a surface that is not only smooth but also highly consistent in thickness and roughness.

The chrome plating process creates a uniform layer that minimizes surface irregularities. This uniformity ensures that the rod performs reliably in high-precision environments, such as hydraulic systems and pneumatic cylinders. The smooth surface reduces friction, allowing components to move seamlessly and improving overall efficiency.

How Chrome Plating Improves Precision

Chrome plating achieves remarkable precision by controlling the thickness and roughness of the surface layer. Studies show that the surface layer thickness is quantified through cross-section analysis, ensuring consistent measurements. Surface roughness, a key indicator of smoothness, is generally less than 0.2 microns. This level of precision allows machinery to operate with minimal wear and tear, extending its lifespan.

| Analysis Type | Result |

|---|---|

| Surface Layer Thickness | Quantified through cross-section studies |

| Surface Roughness | Roughness generally less than 0.2 microns |

Testing methods like ASTM B-568 and ASTM B-504 further validate the accuracy of chrome plating. These methods measure coating thickness and ensure that the plating adheres to strict industrial standards. For example, ASTM B-556 evaluates thin chromium coatings, confirming their reliability in high-performance applications.

| Testing Method | Description |

|---|---|

| ASTM B-568 | Measurement of Coating Thickness by X-Ray Spectrometry |

| ASTM B-504 | Measurement of Thickness of Metallic Coatings by the Coulometric Method |

| ASTM B-556 | Measurement of Thin Chromium Coatings by Spot Test |

Benefits of a Smooth Surface Finish

A smooth surface finish offers several advantages. It reduces friction between moving parts, which lowers energy consumption and enhances efficiency. The chrome-plated finish also improves lubrication retention, ensuring that machinery operates smoothly even under heavy loads. These benefits translate into reduced maintenance costs and longer operational life for your equipment.

The smoothness of chrome-plated rods is measured in multiple places around the circumference to ensure consistency. This meticulous approach guarantees that the rods meet the highest standards of precision and performance.

| Measurement Aspect | Findings |

|---|---|

| Surface Roughness | Generally less than 0.2 microns |

| Thickness Variability | Measured in four or five places around the wire circumference |

By choosing chrome-plated rods, you gain the advantages of enhanced precision and a flawless surface finish. These benefits make them ideal for industries that demand accuracy, reliability, and efficiency.

Applications of Chrome-Plated Rods

Hydraulic Systems and Pneumatic Cylinders

Hydraulic systems and pneumatic cylinders rely heavily on chrome-plated rods for their functionality. These systems operate under high pressure and require components that can endure extreme stress without compromising performance. Chrome plating enhances the durability and wear protection of rods, making them ideal for these demanding applications. The smooth surface coating reduces friction, ensuring efficient movement of pistons within the cylinders.

In hydraulic systems, chrome-plated rods act as piston rods, transferring force and maintaining precision. Their superior corrosion resistance ensures reliable operation even in environments exposed to moisture or chemicals. For pneumatic cylinders, the smooth surface finish of these rods minimizes air leakage, improving energy efficiency and reducing operational costs. By using chrome-plated products in these systems, you can achieve consistent performance and extend the lifespan of your industrial equipment.

Heavy Machinery and Construction Equipment

Heavy machinery and construction equipment operate in some of the harshest conditions, including exposure to dirt, debris, and extreme weather. Chrome-plated rods play a crucial role in maintaining the reliability of these machines. Their hard chrome plating provides exceptional wear resistance, allowing them to withstand the constant friction and impact experienced during operation.

For example, excavators, bulldozers, and cranes use chrome-plated rods in their hydraulic cylinders to lift and move heavy loads. The chromium plating not only enhances the strength of the rods but also protects them from rust and corrosion. This ensures that the equipment remains operational for extended periods, reducing downtime and maintenance costs. The quality of chrome plating applications in heavy machinery directly impacts the efficiency and safety of construction projects.

Manufacturing and Automation Processes

The manufacturing and automation industries demand precision and efficiency, making chrome-plated rods indispensable in these fields. These rods are used in various commercial applications, such as robotic arms, conveyor systems, and automated assembly lines. Their smooth surface coating ensures accurate movement and reduces wear, which is critical for maintaining the precision required in automated processes.

The market for hard chrome plated steel bars, valued at $1.2 billion in 2022, is projected to grow to $1.8 billion by 2033. This growth reflects the increasing demand for high-performance materials in manufacturing and automation. Chrome plating enhances the hardness and corrosion resistance of steel, making it suitable for high-load applications. As automation continues to advance, the need for reliable and durable components like chrome-plated rods will only increase.

In addition to their durability, these rods offer superior corrosion resistance, ensuring long-term performance in industrial environments. Their ability to withstand high loads and maintain precision makes them a preferred choice for manufacturers looking to optimize production processes. By incorporating chrome-plated rods into your automation systems, you can improve efficiency and reduce maintenance costs.

Aerospace and Automotive Components

The aerospace and automotive industries demand components that deliver exceptional reliability and durability. Chrome-plated rods have become a cornerstone in these sectors due to their ability to enhance performance under extreme conditions. Whether in the high-pressure environment of an aircraft or the rigorous demands of a vehicle engine, these rods ensure optimal functionality.

In aerospace applications, chrome plating provides a hard, wear-resistant surface that withstands the intense friction and stress experienced during flight. For example, landing gear systems rely on plated rods to absorb shock and maintain structural integrity. The smooth surface finish of these rods reduces friction, ensuring seamless operation and extending the lifespan of critical components.

In the automotive sector, chrome-plated rods play a vital role in engines, suspension systems, and braking mechanisms. Their corrosion resistance protects against moisture and chemicals, which are common in automotive environments. This feature ensures that components like piston rods and shock absorbers remain functional even after prolonged exposure to harsh conditions. By using these rods, you can improve vehicle performance while reducing maintenance costs.

The benefits of chrome-plated rods in aerospace and automotive components are supported by rigorous testing. The table below highlights their key advantages:

| Benefit | Description |

|---|---|

| Enhanced Durability | Chrome coating increases the lifespan of components by providing a hard, wear-resistant surface. |

| Corrosion Resistance | Acts as a barrier against moisture and chemicals, preventing rust and degradation. |

| Wear Resistance | Protects against damage from friction and wear, ensuring reliability in harsh environments. |

These benefits make chrome-plated rods indispensable in industries where safety and efficiency are paramount. Their ability to withstand extreme conditions while maintaining precision ensures that your aerospace and automotive systems operate at peak performance. By incorporating these rods into your designs, you can achieve greater reliability and cost-effectiveness.

The Chrome Plating Process

Overview of the Plating Procedure

The chrome plating process transforms ordinary metal rods into high-performance components. This procedure involves several carefully executed steps to ensure the coating adheres properly and delivers the desired benefits.

- Degreasing removes heavy dirt and oil from the surface of the rod.

- Manual cleaning eliminates residual impurities, ensuring the surface is spotless.

- Pretreatment prepares the substrate for plating, enhancing adhesion.

- Immersion in the chrome plating vat allows the rod to reach the solution’s temperature.

- Application of plating current deposits the chrome layer, achieving the target thickness.

After plating, post-treatment steps like hydrogen embrittlement relief further improve the rod’s durability. These steps ensure the chrome plating process delivers a flawless finish and optimal performance.

Tip: Proper cleaning and pretreatment are critical for achieving a durable chrome layer. Neglecting these steps can compromise the rod’s functionality.

How Chrome Plating Improves Performance

Chrome plating enhances the functionality of rods by improving their surface hardness, corrosion resistance, and wear resistance. The process creates a hard, smooth layer that withstands extreme conditions and extends the rod’s lifespan.

| Performance Dimension | Technical Parameters | Application Cases |

|---|---|---|

| Surface Hardness | HV 850–1100; Thickness: 5–50 μm | Hydraulic pistons, Automotive engine parts, Aerospace actuator rods |

| Corrosion Resistance | Salt spray test: ≥200 hrs (ASTM B117); Chromium oxide passive layer formation | Industrial rollers, Marine valves, Outdoor equipment |

| Wear Resistance | Coefficient of friction: ~0.15–0.20; Low abrasive wear rate | Injection mold components, Bearings, Robotic shafts |

For example, chrome plating on shock absorber piston rods increases surface hardness and reduces wear. This improvement ensures smoother operation and longer service life. Similarly, rods used in marine environments benefit from enhanced corrosion resistance, protecting them from saltwater exposure.

The chrome plating process also boosts efficiency in high-stress applications. The low coefficient of friction minimizes energy loss, while the uniform surface finish ensures consistent performance. These advantages make chrome plating indispensable for industries requiring reliable and durable components.

Considerations for Using Chrome-Plated Rods

Maintenance and Re-Plating Requirements

Proper maintenance ensures the longevity and performance of chrome-plated rods. You should follow a structured maintenance schedule to keep these rods in optimal condition.

- Daily Maintenance: Clean electrical components, adjust the tank’s liquid level, and monitor the bath’s temperature.

- Weekly Maintenance: Clean the anodes, inspect rectifier cables, and analyze the chromic acid levels.

- Semi-Annual Maintenance: Clean the tank thoroughly, inspect rectifiers, and check for leaks.

In addition to these steps, regular cleaning of the chrome-plated surface is essential. Avoid harsh chemicals or solvents that could damage the finish. Immediate repair of any damage, such as scratches or dents, prevents rust formation and ensures continued protection. Proper handling during use also minimizes risks of wear and tear, extending the rod’s lifespan.

Environmental Impact and Sustainability

The environmental impact of chrome plating has been a topic of concern, but advancements in technology have improved sustainability. Trivalent chromium, a safer alternative to hexavalent chromium, reduces health risks and minimizes hazardous waste. This switch also lowers environmental contamination and operational costs by requiring less energy and operating at lower temperatures.

Recycling chromium from industrial waste further reduces environmental damage. Studies show that recovering chromium from waste generates up to 95.65% less environmental harm compared to raw chromium production. However, challenges remain, as 90% of the energy used in recovery comes from non-renewable sources. Despite these challenges, adopting sustainable practices in chrome plating contributes to better environmental protection.

Comparing Chrome-Plated Rods to Alternative Solutions

When comparing chrome-plated rods to alternatives, trivalent chromium plating stands out for its economic and technical advantages. It generates less hydroxide sludge, reducing disposal costs. The process also allows for rinse water recycling, making it more environmentally friendly.

From a performance perspective, trivalent plating offers equivalent or superior hardness, corrosion resistance, and plating rates compared to hexavalent chromium. It also tolerates current interruptions better and provides improved throwing power. These features make it a reliable choice for industries seeking durable and efficient solutions. By choosing chrome-plated rods, you gain superior protection and long-term cost savings.

Chrome-plated rods have become indispensable in modern industries. Their durability, corrosion resistance, and precision make them essential for improving machinery performance and reducing costs. You can find these rods in applications ranging from hydraulic systems to aerospace components, showcasing their versatility.

Looking Ahead: As industries adopt greener practices, chrome-plated rods will play a key role in advancing sustainable technologies. Their ability to enhance efficiency while minimizing waste ensures they remain a cornerstone of industrial innovation. By choosing these rods, you contribute to a future of reliable and eco-friendly solutions.

FAQ

What makes chrome-plated rods different from other materials?

Chrome-plated rods stand out due to their durability, corrosion resistance, and smooth surface finish. These features improve machinery performance and reduce maintenance costs. Their hard chrome layer also provides wear resistance, making them ideal for high-stress industrial applications.

How do you maintain chrome-plated rods?

Regular cleaning and inspection are essential. Use soft cloths and avoid harsh chemicals to protect the chrome layer. Check for scratches or dents and repair them promptly. Follow a structured maintenance schedule to ensure optimal performance and extend the rod’s lifespan.

Are chrome-plated rods environmentally friendly?

Modern chrome plating uses trivalent chromium, which is safer and reduces hazardous waste. Recycling chromium from industrial processes further minimizes environmental impact. These advancements make chrome-plated rods a more sustainable choice for industries.

Can chrome-plated rods be used in extreme conditions?

Yes, chrome-plated rods perform well in harsh environments. Their corrosion resistance protects against moisture and chemicals, while their wear resistance ensures reliability under high stress. Industries like aerospace and construction rely on these rods for demanding applications.

What industries benefit most from chrome-plated rods?

Hydraulic systems, heavy machinery, manufacturing, aerospace, and automotive sectors benefit greatly. These rods enhance precision, durability, and efficiency, making them indispensable for applications requiring reliable and long-lasting components.