Designers achieve high strength in powder metal parts by optimizing process parameters and material choices. Recent studies show that layer rotation angles, laser power, and scanning speed play a major role in boosting tensile properties of powder metal part components:

| Study | Key Findings |

|---|---|

| Song et al. | Increased tensile strength with a 47° rotation angle between layers in powder metal parts. |

| Chu et al. | Maximum tensile strength at 15° rotation angle; minimum at 90° for powder metal part samples. |

| Gupta et al. | Layer rotation improves micro-hardness, tensile strength, and elongation in powder metal parts. |

| Jia et al. | Interlayer rotation and scanning vector rotation enhance heat flow direction, leading to better mechanical properties in powder metal part production. |

| Aboulkhair et al. | Optimal parameters: scanning speed of 500 mm/s, hatch spacing of 50 μm, laser power of 100 W for high-density powder metal parts. |

| Read et al. | Interaction of laser power and scanning speed significantly impacts porosity in powder metal part fabrication. |

| Majeed et al. | Ideal parameters for surface quality: laser power of 0.32 kW, scanning speed of 0.60 m/s, overlap rate of 35%, hatch distance of 88.7 mm for powder metal parts. |

Tensile strength directly affects the reliability of powder metal part components. Electron beam melted Ti6Al4V specimens show superior tensile and fatigue properties, highlighting the importance of strength in powder metallurgy. Design choices, such as geometry and consolidation, enable powder metal part manufacturers to meet high performance demands and support efficient, high-volume production.

Latest trends in powder metallurgy for powder metal parts include:

- Complex geometry and consolidation for improved integrity.

- Waste reduction compared to traditional methods.

- Flexible material composition for high-stress uses.

- Cost-effective large-scale production.

Material Selection for High Strength in Powder Metallurgy

Choosing High-Strength Base Powders

Selecting the right base powder is the first step in achieving high strength for powder metal parts. Engineers often choose materials based on their ultimate tensile strength and mechanical properties. The table below shows common powder metallurgy materials and their typical ultimate tensile strength values:

| Material Type | Composition | Ultimate Strength (MPa) |

|---|---|---|

| PM Nickel Steel | Fe, 96%, Ni-2%, C-0.5% | N/A |

| PM Infiltrated Iron | Fe, 78%, Cu-20% | N/A |

| PM Stainless Steel (AISI 316) | SS-316N1-25 | 390 |

| PM Iron | Unalloyed PM Iron | 120 – 260 |

| Iron-Copper | Blend of iron and copper | 340 – 690 |

| Copper-Infiltrated Iron and Steel | Various compositions | 350 – 830 |

Engineers select iron-copper blends and copper-infiltrated iron for applications that demand high strength and reliable tensile properties. Stainless steel powders, such as AISI 316, offer good mechanical performance and corrosion resistance. The choice of base powder directly affects the microstructure and ultimate tensile strength of the finished component.

Role of Alloying Elements in Strength Enhancement

Alloying elements play a key role in improving the strength of powder metal parts. Nickel, molybdenum, and copper are common additions. These elements change the microstructure and boost mechanical properties. The table below explains how each alloying element affects tensile strength:

| Alloying Element | Effect on Microstructure | Effect on Tensile Strength |

|---|---|---|

| Nickel | Forms bainitic and martensitic structures | Improves hardness and tensile strength |

| Molybdenum | Enhances mechanical properties | Increases tensile strength |

| Copper | Not specified | Not specified |

Nickel helps create strong bainitic and martensitic structures, which increase hardness and tensile strength. Molybdenum improves mechanical properties and raises tensile strength. Copper is often used in blends to enhance overall performance, especially in automotive and industrial manufacturing. The right alloy combination ensures that powder metal parts meet demanding mechanical requirements.

Purity and Consistency Considerations

Powder purity and consistency are critical for achieving high strength in powder metallurgy. High-purity powders melt and solidify more evenly, which prevents unwanted microstructures. Consistent chemical composition leads to reliable mechanical properties and better performance. Spherical powders offer improved packing density and flowability, which help create strong and defect-free parts.

Good flowability and high packing density improve overall build quality and reduce defects. Spherical powders enhance packing density and flowability, leading to better mechanical properties. Increased packing density contributes to a more consistent powder layer, preventing fluid instabilities.

The build process can change powder composition, so engineers monitor chemical composition and morphology closely. Studies show that finer grain sizes, achieved through powder metallurgy, result in superior tensile properties compared to traditional methods. Maintaining powder purity and consistency helps manufacturers produce powder metal parts with high strength and excellent ultimate tensile strength.

| Aspect | Evidence |

|---|---|

| Chemical Composition | The chemical composition of the powder affects the final build’s properties, including tensile strength. |

| Powder Purity | High purity influences melting and solidification, while impurities can lead to undesirable microstructures. |

| Morphology and Size | Spherical powders have better packing density and flowability, which are crucial for mechanical properties. |

| Build Process Changes | The build process can alter powder composition, affecting the final product’s tensile strength. |

Manufacturers address challenges such as poor powder flowability, contamination, and density variation by using controlled particle size, clean environments, and optimized compaction parameters. These strategies ensure that powder metal parts deliver consistent mechanical performance and meet high strength requirements.

Particle Engineering to Maximize Powder Metal Part Strength

Particle Size Optimization

Engineers know that particle size plays a key role in powder metallurgy. Medium-sized powders often deliver the best mechanical properties for powder metal part production. Fine powders can improve surface finish, but they may cause poor flow during manufacturing. Coarse powders flow better, but they do not always provide high strength. Studies show that medium-sized powders create a balanced microstructure, which leads to improved tensile properties. This balance helps manufacturers achieve strong and reliable parts that perform well in tensile tests.

Particle Shape and Distribution

The shape and distribution of powder particles affect the mechanical behavior of the final part. Spherical particles pack together more tightly, which increases density and strength. Irregular shapes can create gaps or voids, lowering mechanical properties. A uniform particle size distribution is important for consistent strength and performance. Research shows that the right distribution improves tensile strength and overall mechanical properties. When engineers select powders with the correct shape and distribution, they help control the microstructure and enhance the mechanical behavior of the finished part.

Blending Techniques for Uniformity

Blending powders is a critical step in powder metallurgy. Rotary batch blenders provide gentle mixing, which keeps the powder particles intact and boosts green strength. Uniform blending ensures that each part of the mixture has the same composition. This uniformity reduces voids and improves powder cohesion. As a result, the final product shows balanced mechanical properties and high strength. Manufacturers rely on these blending techniques to produce powder metal parts that meet strict performance standards. Consistent blending also supports the even distribution of alloy elements, which further improves the mechanical behavior of the part.

Compaction Methods for High Strength Powder Metal Parts

High-Pressure Compaction

High-pressure compaction stands as a key process in powder metallurgy for producing parts with high strength. Engineers apply pressures between 100 and 300 MPa to compact powder particles tightly together. This pressure range creates an optimal balance between bonding area and bonding strength. When powders with intermediate hardness undergo these pressures, tablet tensile strength reaches its maximum. The process reduces gaps between particles, which increases density and improves tensile properties. High-pressure compaction also helps control the microstructure, leading to better mechanical properties and reliable performance in finished components.

- Typical compaction pressures range from 100 to 300 MPa.

- Maximum tensile strength occurs with intermediate hardness materials.

- The interplay between bonding area and bonding strength is optimal at these pressures.

Warm die compaction further enhances results. Heating the tooling cavity to about 220°F before pressing the powder minimizes friction and improves powder flow. This method increases deformation under pressure, which helps the powder fill the die more completely. The result is higher density and improved mechanical properties, crucial for achieving high strength in powder metal part manufacturing.

Isostatic Pressing vs. Uniaxial Pressing

Isostatic pressing and uniaxial pressing represent two main methods for compacting powder. Isostatic pressing applies pressure evenly from all directions, which produces parts with uniform density and strength. This method reduces the risk of weak spots and improves overall mechanical properties. Uniaxial pressing uses pressure from one direction, usually in a vertical axis. While uniaxial pressing is faster and more cost-effective, it may create density gradients in the part.

High velocity compaction (HVC) can be combined with these methods to increase green body density. When engineers use HVC with mold wall lubrication, densities can reach up to 7.7 g/cm³. This increase in density leads to better tensile properties, yield strength, and hardness. The choice between isostatic and uniaxial pressing depends on the desired mechanical properties and the complexity of the part’s geometry.

Tip: Isostatic pressing is ideal for complex shapes and critical applications where uniform strength is required. Uniaxial pressing suits simpler designs and high-volume production.

Lubrication and Die Design

Lubrication and die design play a vital role in the compaction process. Lubricants decrease friction among powder particles and between the particles and die walls. This reduction in friction allows powder to move more freely during compaction, which enhances compressibility and helps achieve greater density. Proper lubrication also boosts green strength and makes it easier to eject parts from the die, prolonging equipment life.

- Compressibility is crucial for densification under pressure.

- Lubricants facilitate particle movement during compaction, enhancing compressibility.

- Proper lubrication boosts green strength and aids in part ejection.

| Aspect | Findings |

|---|---|

| Role of Lubricants | Reduces friction, enhances compressibility, affects green strength during die compaction. |

| Die Design Influence | Critical in determining final properties of compacted parts. |

| Compaction Stages | Initial: particle rearrangement; Intermediate: elastic-plastic deformation; Final: bulk deformation. |

| Green Strength | Increases with compaction pressure; varies with lubricant addition. |

Die design determines how pressure is distributed during compaction. Well-designed dies ensure uniform density and minimize defects. Engineers focus on die geometry to support the desired microstructure and mechanical properties. The combination of effective lubrication and precise die design leads to powder metal parts with high strength and excellent tensile properties.

Sintering Techniques in Powder Metallurgy for Strength

Controlled Atmosphere Sintering

Engineers use controlled atmosphere sintering to improve the strength of powder metal parts. The right atmosphere prevents unwanted reactions, such as oxidation, during heating. Different materials need different atmospheres and temperatures. The table below shows common conditions for sintering metals:

| Material | Sintering Temperature (°F) | Atmosphere | Key Considerations |

|---|---|---|---|

| Steel | 2050 to 2400 | Nitrogen-rich, endothermic gas, or vacuum | Critical oxidation control; energy consumption |

| Iron | 2010 to 2100 | Endothermic gas or nitrogen/hydrogen mix | Manage oxidation control |

| Bronze | 1470 to 1560 | Hydrogen or reducing environments | Dimensional control is key |

| Brass | 1600 to 1700 | Inert or reducing, often hydrogen | Precise control of time and atmosphere essential |

A controlled atmosphere leads to tighter dimensional tolerances, cleaner surfaces, and faster production. It also lowers total cost and gives more design flexibility. These benefits help manufacturers create powder metal parts with high strength and reliable mechanical properties.

Temperature and Time Optimization

Temperature and time play a big role in the sintering process. Engineers often set the sintering temperature around 1150 °C to achieve high tensile strength. This temperature helps the powder particles bond well, which improves the microstructure. If the temperature is too low, the part may not reach the needed density. If it is too high, the part can lose shape or develop unwanted phases. Careful control of time and temperature ensures the final part has strong mechanical properties and meets manufacturing standards.

Advanced Sintering Methods

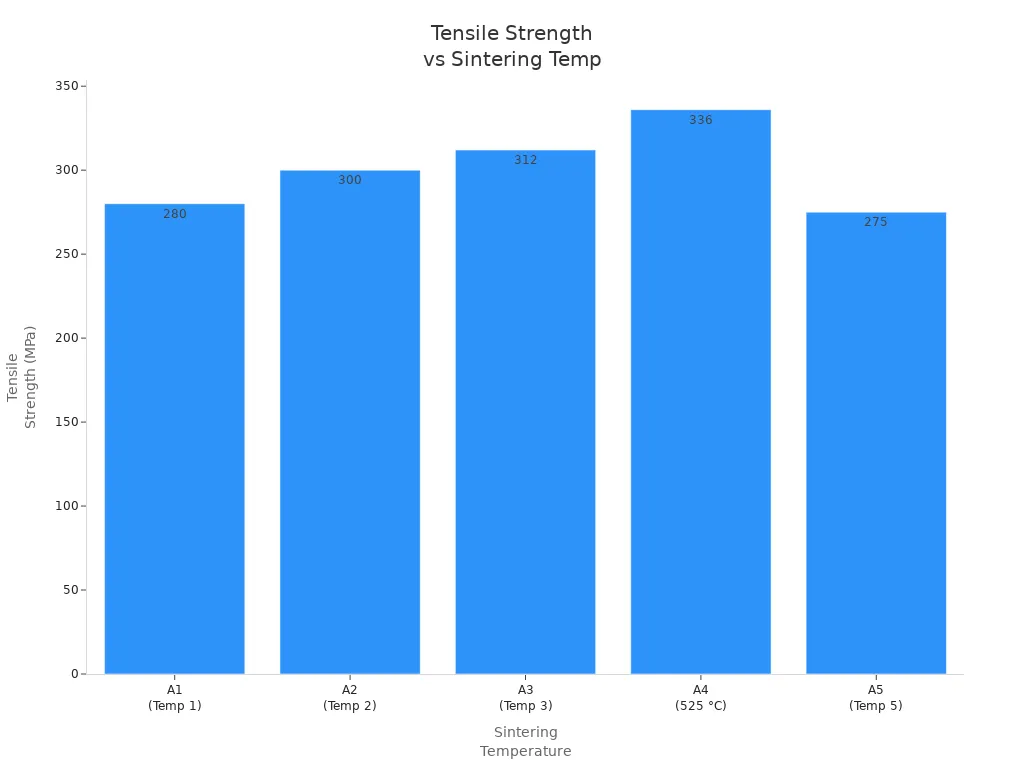

Advanced sintering methods can boost the strength of powder metal parts even more. Mechanical alloying mixes powders at a fine scale, which improves the microstructure. Spark plasma sintering uses electric current and pressure to bond the powder quickly. These methods help create alloys with very high tensile strength. For example, a study showed that adding titanium to a high entropy alloy and using spark plasma sintering led to an ultimate tensile strength of about 1600 MPa. The chart below shows how tensile strength changes with different sintering temperatures:

These advanced techniques help engineers control the microstructure and improve the mechanical properties of powder metal parts. They support the production of strong, reliable components for many industries.

Post-Processing Treatments to Enhance Powder Metal Part Strength

Heat Treatment for Strength Enhancement

Heat treatment changes the structure of powder metal parts to improve their strength. Engineers use several methods to achieve better results:

- Induction hardening increases strength by heating the surface quickly and then cooling it. This process works well for many alloy types but needs careful control to prevent rust.

- Water-based quenchants cool parts fast and boost strength, but they can cause corrosion. Oil quenching cools more slowly, which helps reduce cracking and distortion.

- Proper racking during heat treatment keeps parts spaced evenly. This ensures even heating and helps avoid warping.

These steps help powder metal parts reach higher tensile strength and better mechanical properties. Heat treatment remains a key step in manufacturing strong components.

Densification Processes

Densification processes like hot isostatic pressing (HIP) make powder metal parts stronger by reducing empty spaces inside the material. HIP uses high pressure and heat to squeeze the powder, making it denser and more uniform. The table below shows how HIP improves strength and other properties:

| Benefit of HIP | Description |

|---|---|

| Reduced Porosity | Fewer empty spaces mean higher ductility and yield stress, which increases strength. |

| Faster Center Densification | The center of the part becomes dense quickly, leading to better isotropy and strength. |

| Full Theoretical Density | HIP can achieve maximum possible density, reducing property scatter and improving strength. |

| Improved Isotropy | Uniform pressure creates even mechanical properties in all directions. |

| Enhanced Physical Properties | Fine grain size and less directionality boost tensile strength and overall performance. |

Densification ensures powder metal parts have reliable mechanical properties for demanding uses.

Surface Treatments and Coatings

Surface treatments and coatings protect powder metal parts and make them last longer. These treatments create a smooth, uniform surface that resists acid, alkali, and wear. The table below lists key features of modern coatings:

| Feature | Description |

|---|---|

| Smooth and Uniform Surface | Strong resistance to acid, alkali, and wear. |

| High Efficiency | One-time film formation increases productivity by 30-40%. |

| Energy Saving | Uses about 30% less energy than traditional methods. |

| Less Pollution | No harmful solvent vapors, making it safer for the environment. |

| High Paint Utilization Rate | Up to 95% of powder can be reused, reducing waste. |

| Good Film Performance | Thick, well-adhered coating improves corrosion resistance and durability. |

| Durability | Parts resist fading, cracking, and scratching. |

| Environmentally Friendly | No harmful chemicals or solvents, minimal waste produced. |

These coatings help powder metal parts keep their strength and mechanical properties over time, even in tough environments.

Practical Design Tips for High Strength Powder Metal Parts

Geometry and Wall Thickness Considerations

Engineers know that the geometry of a powder metal part affects its strength. Wall thickness plays a major role in how much load a part can handle. Thinner walls often lead to a large drop in strength. For example:

- Thinner walls can reduce yield strength by up to 33%.

- Ultimate tensile strength may decrease by as much as 30% compared to thicker parts.

- The minimum wall thickness for powder metallurgy usually falls between 0.06 and 0.08 inches.

- Thin cross-sections can make parts fragile. Long, thin walls may break or distort during heat treatment.

Designers should avoid making walls too thin. Keeping wall thickness within recommended limits helps maintain strong mechanical properties and prevents unexpected failures.

Minimizing Stress Concentrations

Stress concentrations can weaken powder metal parts. Careful design helps spread out forces and protect the part from cracking. Engineers use several strategies to reduce stress:

- Add gradual transitions to ease changes in shape.

- Use relief notches to remove material near notches and lower stress.

- Choose several small relief notches instead of one long notch to smooth out stress lines.

- Avoid sharp corners. Use fillet radii to create gradual changes in cross-section.

These steps help keep the strength of the part high and improve its mechanical performance.

Tolerances and Quality Control

Tight tolerances and strong quality control ensure powder metal parts meet strength goals. Manufacturers use several methods to check quality:

- Process monitoring tracks each step in manufacturing to catch problems early.

- Inspection and testing check if parts meet standards. Engineers use physical exams and different tests to measure properties.

- Quality assurance and documentation prevent defects and keep records for every batch.

These practices help maintain consistent strength and mechanical properties in every powder metal part. Careful control at each stage supports reliable performance in demanding applications.

Real-World Applications and Case Studies of High Strength Powder Metal Parts

Automotive Components

Automotive engineers rely on powder metal parts for many critical applications. These components must meet strict requirements for strength and durability. Turbochargers, exhaust manifolds, and valve seats all use powder metal technology. Each of these parts needs high ultimate tensile strength to perform well under stress. The table below shows the typical strength values for these automotive components:

| Component Application | Ultimate Tensile Strength |

|---|---|

| Turbochargers | 750-950 MPa |

| Exhaust Manifolds | 750-950 MPa |

| Valve Seats | 750-950 MPa |

Manufacturers choose powder metal for these parts because it provides consistent strength and supports complex shapes. This approach helps vehicles run efficiently and safely.

Industrial Machinery Parts

Industrial machinery often uses powder metal parts to improve performance and reliability. These components offer several advantages:

- Lower total cost of ownership by removing extra assembly and machining steps.

- Improved structural strength and repeatability because of uniform density and tight tolerances.

- Faster, cleaner installation during final assembly, which boosts operational efficiency.

- Streamlined design that makes manufacturing easier and improves the look of the product.

- Elimination of multiple components, which simplifies inventory management.

- Decreased assembly time and labor costs, leading to better efficiency.

- Enhanced appearance and performance, which increases reliability.

- Cost savings of about $1.00 per assembly, showing clear economic benefits.

These benefits make powder metal parts a smart choice for many types of industrial equipment.

Aerospace Components

Aerospace engineers use powder metal parts in critical structures. These components must deliver high strength, resist corrosion, and withstand extreme temperatures. The table below highlights important properties and their applications in aerospace:

| Property | Description | Application in Aerospace |

|---|---|---|

| High Tensile Strength | Powder metal components exhibit high tensile strength, essential for safety. | Used in critical aerospace structures. |

| Corrosion Resistance | Alloys resist corrosion, vital for extreme environments. | Suitable for space and battlefield conditions. |

| Temperature Resistance | Components can withstand high temperatures, ensuring durability. | Important for aerospace applications. |

Powder metal technology allows for the production of parts that meet the demanding needs of aerospace systems. These parts help ensure safety and long-term performance in challenging environments.

Engineers can maximize tensile strength in powder metal parts by focusing on smart design and careful process control. Early design choices matter:

- Use a 2-to-1 fill ratio for proper compaction.

- Select unique tool members for complex shapes.

- Ensure powder flows well and fills the die cavity evenly.

- Keep wall thickness above 1.52 mm to avoid density issues.

Ongoing evaluation also helps:

- Adjust processing parameters for better performance.

- Apply interlayer and scanning vector rotation for uniform properties.

These steps support strong, reliable powder metal components.

FAQ

What factors most influence tensile strength in powder metal parts?

Engineers find that material selection, particle size, compaction pressure, and sintering temperature have the greatest impact. Studies show that optimizing these variables leads to stronger, more reliable powder metal components for automotive, industrial, and aerospace applications.

How does wall thickness affect powder metal part strength?

Thicker walls increase tensile strength and durability. Data shows that reducing wall thickness by half can lower yield strength by up to 33%. Designers recommend keeping wall thickness above 0.06 inches for most powder metal parts.

Why do manufacturers use high-performance alloys in powder metallurgy?

High-performance alloys provide superior tensile strength, corrosion resistance, and temperature stability. These alloys help powder metal parts meet demanding requirements in industries such as aerospace and automotive, where reliability and safety matter most.

What is the role of heat treatment in powder metal part production?

Heat treatment changes the microstructure of powder metal parts. Induction hardening and quenching increase strength and hardness. Evidence shows that proper heat treatment improves mechanical properties and extends part life.

How do surface coatings improve powder metal part performance?

Surface coatings protect powder metal parts from corrosion, wear, and chemical damage. Modern coatings form a smooth, durable layer. Data indicates that coated parts last longer and maintain their strength in harsh environments.