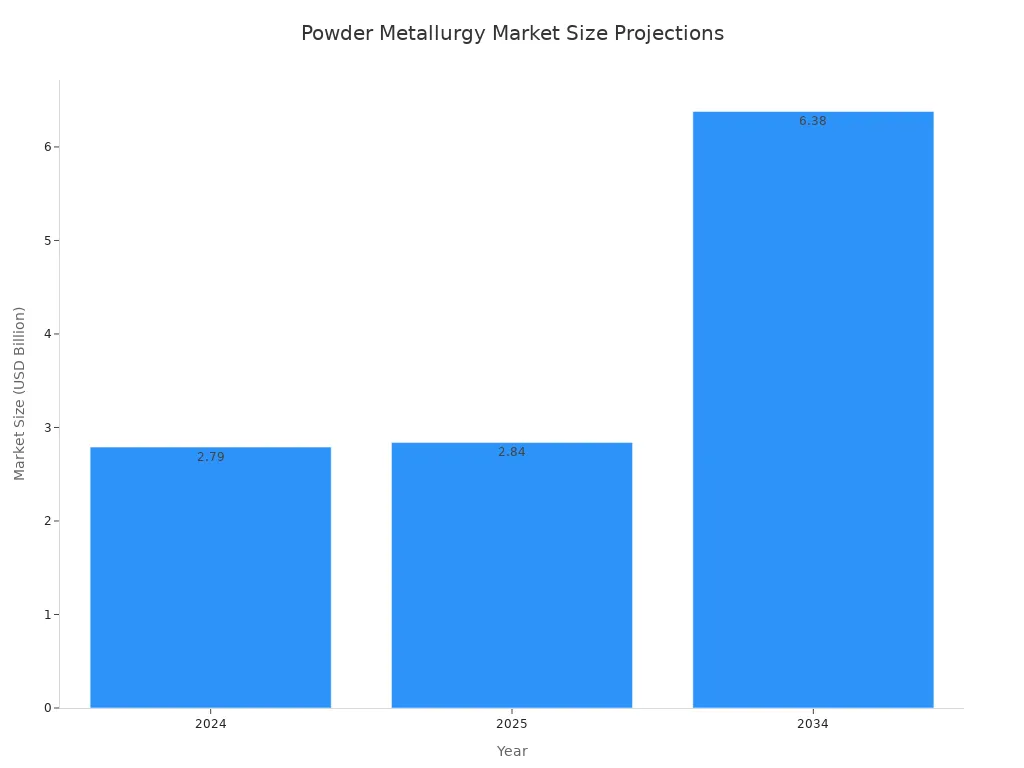

The advantages of powder metallurgy are significant. They include superior material utilization, excellent design flexibility, and cost-effectiveness. These benefits make the process ideal for high-volume production of complex parts. The industry’s projected growth highlights its rising importance in modern manufacturing.

Note: The process in powder metallurgy uses metal powder to create components. This unique production method achieves nearly 97% material utilization from the initial powder. The powder metallurgy method allows for complex designs with minimal waste, making it suitable for a large volume of parts.

Understanding the Process in Powder Metallurgy

The powder metallurgy manufacturing process transforms fine metal powder into solid, functional components. This unique production method consists of three primary stages. Each step contributes to the final part’s strength, accuracy, and overall quality. The entire process in powder metallurgy is designed for efficiency and precision.

Powder Production and Blending

The journey begins with the creation of metal powder. Manufacturers use several methods to produce powder with specific characteristics. The two most common techniques are:

- Atomization: A stream of molten metal is broken apart by high-pressure gas or liquid jets. The tiny droplets cool and solidify into powder particles. This method offers high production rates and is suitable for many metals, including iron, steel, and aluminum.

- Chemical Reduction: This technique uses a chemical reaction to reduce metal compounds into pure elemental powder. It produces very fine, high-purity powder, which is ideal for specialized applications.

After production, different types of powder may be blended together. Additives like lubricants or alloying elements are also mixed in to improve compaction and achieve the desired properties in the final products.

Compaction to Near-Net Shape

Next, the blended powder is poured into a precision die. A press applies high pressure, typically between 100 and 200 MPa, to compact the powder into a solid shape. This step creates what is known as a “green compact.” This part is dense enough to be handled but has not yet reached its final strength. A key advantage of powder metallurgy is its ability to form parts to their near-net shape.

This capability significantly reduces the need for secondary machining. It saves material, lowers tool costs, and shortens production time. Complex geometries that would require multiple manufacturing steps can often be made in a single press.

Sintering for Final Strength

The final stage is sintering. The green compact is heated in a controlled-atmosphere furnace to a temperature just below the metal’s melting point. This high heat causes the individual powder particles to bond together on an atomic level, a process called solid-state diffusion. The sintering atmosphere, often hydrogen or a vacuum, prevents oxidation and helps create clean, strong bonds. This critical step transforms the fragile compact into a dense, robust component with high dimensional accuracy. The process in powder metallurgy delivers strong and reliable final parts and products.

Key Advantages of Powder Metallurgy

The powder metallurgy process offers distinct benefits that make it a leading choice for modern manufacturing. Its core advantages stem directly from its unique method of building parts from powder. This approach delivers superior efficiency, design freedom, and economic value, especially as production demands grow.

Superior Material Utilization

One of the greatest advantages of powder metallurgy is its exceptional material utilization. Traditional manufacturing, like machining, is a subtractive process. It starts with a solid block of metal and cuts away material to create a part, which generates significant waste. Powder metallurgy, however, is an additive process. It uses only the material needed to form the component.

This efficiency leads to remarkable resource conservation. The high material utilization rate has several key benefits:

- Minimal Waste: The scrap rate for powder metallurgy is often as low as 3%. In contrast, conventional machining can have a scrap rate of up to 50% for complex shapes.

- Cost Reduction: Using nearly all the raw material directly lowers production costs. Companies spend less on raw materials and waste disposal.

- Environmental Sustainability: The process achieves a material utilization rate as high as 97%. This reduces the need for new raw material extraction, consumes less energy, and lowers emissions. Unused powder can also be collected and recycled for future production runs.

Unmatched Design Flexibility

Powder metallurgy provides engineers with unmatched design flexibility. The process can create complex shapes and intricate features that are difficult or impossible to produce with other methods. Since the part is formed in a die, features like undercuts, holes, and multiple levels can be integrated into a single component. This capability simplifies assembly and improves the performance of the final products.

This design flexibility extends to internal structures. Powder metallurgy can produce parts with complex internal channels for cooling or fluid flow. It can also create porous structures with carefully controlled networks of tiny pores. These intricate features are made without adding to the part’s cost, which is a significant advantage over machining, where complexity always increases price. This level of design freedom allows for innovation in fields requiring lightweight or filtered components. The flexibility of the design process is a key strength.

Cost-Effectiveness in Mass Production

The process delivers outstanding cost-effectiveness, particularly for high-volume production. While there is an initial investment in tooling, the per-part cost drops significantly as production volumes increase. This makes powder metallurgy an economical choice when companies need to mass produce parts in the thousands or millions.

The break-even point is a critical factor. Powder metallurgy typically becomes more cost-effective than CNC machining once the production volume reaches several thousand units. At this point, the savings from high material utilization and fast cycle times outweigh the initial tooling costs.

Furthermore, the tooling costs for powder metallurgy are often very competitive.

| Manufacturing Process | Typical Tooling Cost Range |

|---|---|

| Metal Injection Molding (MIM) | $1,400 – $2,800 |

| Die Casting | $1,200 – $4,200 |

| Powder Metallurgy | Often lower than MIM & Die Casting |

Conventional powder metallurgy tooling is generally less expensive than tooling for die casting or metal injection molding. This lower barrier to entry makes the process accessible for a wider range of products and applications, solidifying its position as a go-to solution for efficient, large-scale production.

Enhanced and Customizable Performance

Powder metallurgy offers remarkable flexibility in creating materials with specific, tailored performance characteristics. This control begins at the earliest stage of the process. The use of metal powder allows engineers to create unique alloys and composites that are impossible to make through traditional melting and casting. This material design flexibility is a significant advantage.

Manufacturers can blend different types of powder to achieve custom properties. This opens the door for innovative materials designed for specific challenges, such as reducing friction or improving wear resistance.

- Engineers create Al-WS2 composites for efficient and greener parts. They use powder metallurgy to combine aluminum with tungsten disulfide (WS2) particles, which reduces friction in applications like automotive engines.

- Companies develop Cu–Sn–Zn/Gr metal matrix composites as self-lubricating materials. The process creates a porous structure that holds lubricant oil, providing constant lubrication for components like plain bearings.

This level of material flexibility allows for the creation of parts with built-in functionalities. The ability to control porosity and blend materials provides a powerful tool for innovative product design.

The customization does not end after sintering. The inherent flexibility of powder metallurgy extends to post-sintering treatments. These secondary processes further enhance the mechanical properties of components, allowing a single part design to be adapted for various performance requirements.

| Treatment | Process | Enhancement to Mechanical Properties |

|---|---|---|

| Heat Treatment | Alters the part’s microstructure through controlled heating and cooling. | Relieves internal stresses and improves hardness and fatigue strength. |

| Infiltration | Fills the part’s pores with a lower melting point metal, like copper. | Significantly increases density, strength, and structural integrity. |

These treatments provide another layer of performance flexibility. For example, various heat treatments can fine-tune the final products.

- Carburizing creates a hard, wear-resistant surface on low-carbon steel parts while keeping the core tough and flexible.

- Induction hardening toughens specific areas of a component with minimal distortion, ideal for parts needing localized strength.

- Steam treating forms a protective oxide layer that increases surface hardness, benefiting parts that require both toughness and high-load capacity.

Infiltration is another powerful tool. The process seals the component’s natural porosity. This action dramatically boosts mechanical properties, including tensile strength, ductility, and impact resistance. This flexibility means engineers can create complex shapes with intricate features, knowing they can achieve the exact performance needed for the final application.

PM vs. Traditional Manufacturing Methods

Choosing the right manufacturing process is critical for success. Powder metallurgy offers unique advantages, but its value becomes clearer when compared to conventional metal fabrication methods. Each technique has strengths, and understanding these differences helps engineers select the best option for their specific application.

Comparison with Machining

Machining is a subtractive process. It starts with a solid block of material and cuts away what is not needed. This approach is the opposite of powder metallurgy, which is an additive process that builds a part from powder. This fundamental difference leads to major distinctions in efficiency and cost.

The most significant advantage of powder metallurgy over machining is its superior material utilization.

- Material Waste: Machining can generate a large amount of waste, sometimes as high as 50% of the original material. This scrap metal must be collected and recycled, adding cost and complexity. Powder metallurgy, by contrast, has minimal waste, achieving up to 97% material utilization. This efficiency directly reduces raw material costs and environmental impact.

- Production Speed: For high-volume production, PM is much faster. A part can be compacted in seconds. Machining a complex part can take several minutes or even hours.

- Cost Structure: Machining has low initial setup fees, making it ideal for prototypes and low-volume runs. However, its high material waste and long cycle times make it expensive for mass production. PM has higher initial tooling costs, but the per-part cost drops dramatically with volume, making it more economical for large quantities.

Machining offers excellent precision and is not limited by part size. Yet, for complex parts needed in the thousands, the savings from PM’s high material utilization and speed often outweigh the initial tooling costs. This makes it a smarter choice over conventional metal fabrication for many high-volume applications.

Comparison with Casting

Casting, like powder metallurgy, is a near-net-shape manufacturing process. It involves pouring molten metal into a mold. While both methods reduce the need for secondary operations, they differ in precision, energy use, and material options.

Powder metallurgy often provides better dimensional accuracy and a finer surface finish. PM components can achieve a high dimensional accuracy of around ±0.04 mm after sintering. The surface finish is also very fine, with a typical Roughness Average (Ra) of 1.6 µm. This quality often eliminates the need for extra finishing steps. Investment casting can produce a smooth surface, with Ra values from 1.6 to 6.3 µm, but it can experience greater dimensional changes due to shrinkage as the metal cools.

Energy consumption is another key differentiator. The powder metallurgy process is significantly more energy-efficient. Melting metal for casting is an energy-intensive step. Sintering also uses heat, but the overall energy usage is much lower.

| Process | Energy Consumption per Part |

|---|---|

| Powder Metallurgy | 1.243 kWh |

| Original Manufacturing (Casting) | 2.847 kWh |

This energy saving comes from a more streamlined production flow. For example, making a truck transmission part with PM reduces the process from 17 steps to just 6. This efficiency makes it a greener and more cost-effective manufacturing choice.

Comparison with Stamping and Forging

Stamping and forging are two other forms of conventional metal fabrication that shape metal through force. However, their capabilities and applications are very different from those of powder metallurgy.

Stamping is best for producing simple, two-dimensional parts from flat metal sheets. It is fast and cheap for high volumes of simple shapes like brackets or washers. Its main limitation is geometric complexity. Stamping cannot easily create 3D shapes with varying thicknesses or intricate features. Powder metallurgy excels here, as the powder can be “sculpted” in the die to create complex 3D designs in a single press stroke. For a complicated component, PM often requires only one set of tools, reducing tooling costs compared to the multiple dies needed for progressive stamping.

Forging produces parts with exceptional strength and durability. The process involves heating a metal billet and shaping it with a hammer or press. This creates a continuous grain structure that gives forged parts superior tensile strength and fatigue resistance.

However, forging has its limits. It is not well-suited for creating complex shapes and often requires extensive secondary machining, which creates material waste. Powder metallurgy parts, due to their inherent porosity, are generally not as strong or ductile as forged parts. PM also has size limitations; presses can typically only make parts under 250 mm wide. Forging, on the other hand, can produce very large parts like I-beams. Therefore, forging remains the priority for large products that demand the highest levels of strength and impact resistance.

When to Choose Powder Metallurgy in 2025

Selecting the right manufacturing process is crucial for a project’s success. Powder metallurgy offers a powerful solution for specific challenges. Understanding its ideal uses and design considerations helps engineers make informed decisions in 2025.

Ideal Applications and Industries

Powder metallurgy is a leading choice in industries that require complex, high-volume parts. The automotive sector, for instance, increasingly uses this process. Key components like gears and connecting rods are made with powder metallurgy. This method produces precise gears with complex shapes for electric vehicle (EV) drivetrains. It also creates lightweight connecting rods that improve fuel economy in hybrid vehicles.

The aerospace and medical industries also benefit greatly from this technology.

- Aerospace: This industry needs lightweight parts with high strength. PM creates turbine blades and structural elements from materials like nickel-based superalloys. The process reduces material waste, which is critical when using expensive alloys.

- Medical: The medical field uses powder metallurgy to make surgical instruments and orthopedic implants. The ability to customize material properties ensures biocompatibility and strength for items like knee and hip replacements.

Key Design and Cost Considerations

A successful design for powder metallurgy follows specific rules. Engineers must consider factors like wall thickness. A general rule is to keep walls no thinner than 1.52 mm (0.060 inches). Very thin walls can create fragile tooling and cause issues during powder compaction. Unlike other methods, the sides of PM parts generally do not require a draft or taper for ejection.

Cost is another major factor. The process is most economical for high-volume production. While initial tooling can be an investment, the cost per part drops as the production volume increases. Powder metallurgy becomes highly cost-effective for simpler parts needed in large production volumes. The near-net-shape production minimizes material waste and post-processing, leading to significant long-term savings. This makes it an excellent choice when material costs and production efficiency are top priorities.

The process in powder metallurgy is a leading manufacturing choice for 2025. Its unique design directly enables significant advantages for high-volume production. This method offers a proven and efficient solution for engineers facing challenges with cost, geometric complexity, and waste.

Key Takeaways:

- Design Flexibility: The process allows for complex shapes and products with custom properties. This design flexibility is a major benefit.

- Cost Savings: It drastically cuts waste. By minimizing material waste and other forms of waste, powder metallurgy delivers cost-effective final parts and products. The use of advanced powder helps reduce waste.

FAQ

What makes powder metallurgy good for the environment?

Powder metallurgy is an eco-friendly process. It achieves up to 97% material utilization, creating very little waste. This efficiency reduces the need for new raw materials. The process also consumes less energy compared to traditional methods like casting, lowering its overall environmental impact.

Can powder metallurgy make strong parts?

Yes, powder metallurgy produces strong and durable components. The sintering stage creates powerful atomic bonds between metal particles. Manufacturers can also use secondary treatments to boost performance.

- Infiltration fills pores to increase density and strength.

- Heat treatment improves hardness and wear resistance.

When is powder metallurgy cheaper than machining?

Powder metallurgy becomes more cost-effective than machining for high-volume production runs. While tooling has an initial cost, the fast cycle times and minimal material waste create significant savings. This advantage applies when producing several thousand parts or more.

What industries use powder metallurgy the most?

The automotive industry is a major user of powder metallurgy. It makes complex parts like gears and connecting rods. The aerospace and medical fields also rely on this process. They use it to create lightweight structural components and specialized surgical implants.