When evaluating a potential supplier for sintered parts, there’s one critical question you must ask first: “Can you describe your quality management system and certifications?” This question reveals the supplier’s commitment to quality. A strong supplier provides clear answers about their production processes. This transparency indicates a reliable partner. Poor supplier management directly impacts the quality and cost of your final product.

The High Cost of Poor Supplier Oversight

Source Finding 2022 QIMA benchmark Brands with low supplier engagement saw 32% more critical quality defects. General observation Fragmented supplier networks can increase costs by up to 30% from defects. McKinsey study 45% of quality issues originate from Tier 2 or Tier 3 suppliers.

A capable supplier will welcome your detailed questions about their manufacturing capabilities.

Assessing Quality Control in Sintered Parts Manufacturing

A supplier’s commitment to quality control directly impacts your product’s performance. You need a partner who embeds quality into every stage of the manufacturing process. Asking detailed questions about their systems reveals their capability and reliability. A transparent quality and manufacturing process is the foundation of a strong partnership.

What quality certifications do you hold?

Certifications are not just pieces of paper. They represent a manufacturer’s dedication to proven, repeatable processes. You should look for a supplier with globally recognized certifications. These standards ensure the manufacturer follows strict guidelines for quality management.

Key Certifications to Look For:

- ISO 9001: This is the international standard for a quality management system (QMS). It shows a supplier has established processes for consistency and customer satisfaction.

- IATF 16949: This certification is essential for automotive suppliers. It builds on ISO 9001 with specific requirements for the automotive industry, focusing on defect prevention and waste reduction.

A certified powdered metal parts manufacturer demonstrates a proactive approach to quality assurance. This commitment reduces your risk of receiving defective components.

How do you ensure raw material quality?

The quality of sintered parts begins with the raw materials. A reputable supplier will have a robust system for material quality verification. You should ask about their process for analyzing incoming metal powders. This ensures the powders meet precise chemical and physical specifications before manufacturing begins.

The Metal Powder Industries Federation (MPIF) provides standardized test methods for the industry. A good supplier will follow these or similar standards, such as ISO 5755:2022, which governs the chemical composition of sintered metal materials. This standard ensures the correct mix of metal powders, alloys, and lubricants to achieve the desired properties.

Ask your potential supplier if they perform comprehensive analyses to confirm powder chemistry and purity. Common testing methods include:

| Test Analysis | Methodology / Equipment |

|---|---|

| Bulk Elements | Inductively Coupled Plasma – Atomic/Optical Emission Spectrometry (ICP-AES/OES) |

| Trace Elements | Inductively Coupled Plasma – Mass Spectrometry (ICP-MS) |

| Interstitial Gases | Inert Gas Fusion – LECO |

| Carbon & Sulfur | Combustion – LECO |

Verifying these materials from the start prevents inconsistencies between batches and ensures the final sintered component performs as expected.

What is your process for in-process and final inspection?

Consistent inspection throughout the sintered parts manufacturing process is critical. It allows a supplier to identify and correct issues early, saving time and money. You need to understand their methods for both in-process checks and final inspection and approval.

During manufacturing, non-destructive testing (NDT) methods are vital for checking internal and external integrity without damaging the part. Ask your potential partner what NDT technologies they use. Modern techniques provide a deep look into part quality.

- Resonant Acoustic Method (NDT-RAM™): This technique rapidly inspects the entire part for structural flaws. It is ideal for high-volume production.

- Radiographic and CT Scanning: These methods use X-rays to create detailed images of a part’s internal structure. They are essential for detecting hidden defects like voids, porosity, or cracks in sintered components.

- Thermography: This uses infrared imaging to find surface and near-surface defects. It works well for parts with complex shapes.

For final inspection, density and dimensional accuracy are paramount. The mechanical properties of a sintered part—like strength and hardness—depend directly on its density. Inconsistent density can lead to part failure. Advanced inspection methods enable a manufacturer to verify every single part. For example, low-frequency eddy current testing can check for porosity, micro-cracking, and delamination after the sintering process. This type of inspection can even be performed on fragile “green” parts before they are sintered. Thorough dimensional inspections confirm the part meets your exact specifications.

How do you handle non-conforming parts?

Even the best manufacturing processes can produce parts that do not meet specifications. A critical sign of a reliable supplier is not the absence of errors, but a robust and transparent system for managing them. You must ask a potential partner to detail their process for handling non-conforming components. A strong supplier will have a clear, documented procedure that protects your production line from defects.

Your inquiry should focus on their corrective and preventive action (CAPA) process. Find out how they identify, quarantine, and analyze defective parts. A proactive partner moves beyond simply scrapping bad parts. They perform a root cause analysis to understand exactly why the defect occurred. This investigation is a cornerstone of their quality assurance program. It prevents the same problem from happening again.

A Proactive Supplier’s Non-Conformance Checklist:

- Immediate Containment: Isolate all suspect parts to prevent shipment.

- Root Cause Analysis: Use formal problem-solving methods to find the source of the error.

- Corrective Action: Implement a permanent fix to the process.

- Customer Communication: Provide you with a detailed report on the issue and the solution.

Top-tier manufacturers work tirelessly to minimize non-conformance from the start. They invest heavily in digital technologies to reduce scrap rates and improve overall quality. These suppliers leverage advanced analytics and process controls to achieve higher efficiency.

Ask your potential supplier how they use technology to improve their processes. Leading companies often:

- Implement digital twins to simulate and optimize production.

- Use advanced analytics to refine compaction and sintering stages.

- Integrate real-time process analytics into press lines and ovens.

- Employ simulation-enabled design and predictive maintenance.

This digital approach ensures tighter control over part density, dimensions, and microstructure. It demonstrates a deep commitment to continuous improvement and delivering the highest quality components.

Evaluating Technical Expertise and Engineering Support

A supplier’s value extends beyond their production floor. You need a partner with deep engineering expertise. Their ability to provide technical guidance is crucial for successful manufacturing outcomes. This technological expertise ensures your components are optimized for both performance and cost-effectiveness from the very beginning.

What are your material capabilities?

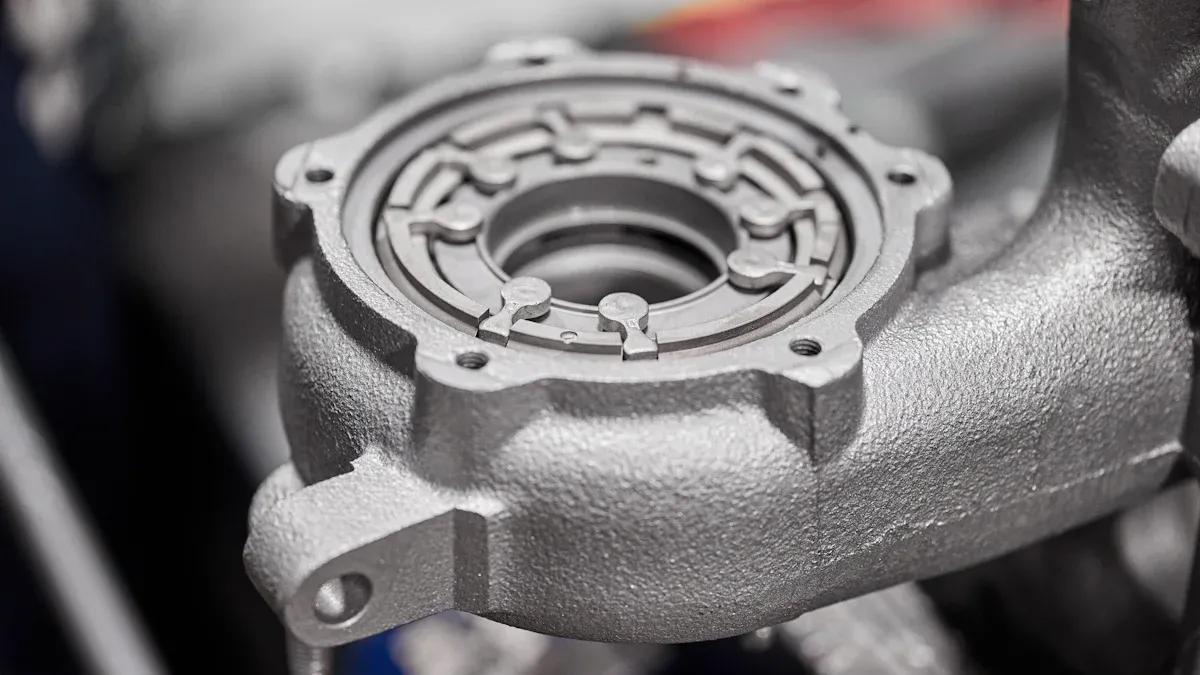

The material you choose directly impacts the final part’s durability and performance. A capable manufacturer will offer a wide range of materials and help you select the best one for your application. You should ask for a complete list of their available steel alloys, which may include 300 and 400 series stainless steel, iron-nickel steel, and sinter-hardened steel. Some suppliers even develop proprietary materials like Alphaloy for high-temperature exhaust applications.

A knowledgeable partner understands how small changes in composition affect mechanical properties. For example, adding copper to iron-based alloys improves toughness and fatigue life. Ask for specific data that shows their understanding of these relationships.

Example: Mechanical Properties of Iron-Based Sintered Alloys

Material Composition Yield Strength (MPa) RBF Fatigue Limit (MPa) FC-0205-30 (Fe-Cu-C) 240 N/A FC-0208-50 (Fe-Cu-C) 380 160

This level of detail demonstrates a supplier’s command over their materials to achieve properties like high strength and wear resistance.

Do you offer Design for Manufacturability (DFM) support?

A proactive supplier will partner with you to refine your component design. This process, known as Design for Manufacturability (DFM), optimizes a part for efficient sintered parts manufacturing. It helps reduce costs, improve quality, and ensure component compatibility within your assembly.

During DFM, the manufacturer’s engineers review your design to identify potential challenges. They may suggest changes to improve material flow during compaction or to achieve tight tolerances more consistently. This collaborative approach prevents costly redesigns later. A supplier offering DFM support shows a commitment to your project’s success, not just fulfilling an order for sintered parts. This partnership is key to achieving the required tolerance and function.

What is your team’s engineering experience?

The quality of engineering support you receive depends on the team’s qualifications and experience. You should inquire about the background of the engineers who will support your project. A strong powdered metal parts manufacturer employs a team with formal education and practical expertise.

Look for engineers with degrees in Metallurgy, Materials Science, or Mechanical Engineering. They should have several years of industrial experience and a deep understanding of powder metallurgy fundamentals. Ask if their team uses structured problem-solving methods like FMEA or 8D. This indicates a disciplined approach to process control and quality improvement. A team with this background has the expertise to provide valuable technical support throughout the manufacturing process.

Can you provide technical support and reports like PPAP?

Technical support should extend to comprehensive documentation. You need proof that a supplier can consistently produce parts that meet your specifications. The Production Part Approval Process (PPAP) is a critical framework for this, especially in the automotive industry. A supplier’s ability to provide a complete PPAP report demonstrates their process control and technical expertise. This documentation ensures part compatibility with your assembly and guarantees long-term performance.

The PPAP report is a collection of documents that validates a manufacturer’s production process. It serves as clear evidence that the supplier can reliably meet your quality standards before full-scale production begins.

When you request a PPAP, you should expect a detailed package. A capable supplier will provide documentation covering every aspect of design and production. This transparency is a key indicator of a reliable partnership. Ask if their report includes the following essential elements:

- Design and Process Documentation: This includes design records, process flow diagrams, and a Control Plan that outlines all inspection methods.

- Failure Mode and Effects Analysis (FMEA): You should receive both a Design FMEA (DFMEA) and a Process FMEA (PFMEA) to show they have proactively identified and mitigated potential risks.

- Measurement and Validation: The report must contain Measurement System Analysis (MSA) to prove their gauges are accurate, along with dimensional results confirming the part meets all specifications.

- Part Submission Warrant (PSW): This is the summary document that formally certifies the part is ready for production.

Receiving a thorough PPAP report gives you confidence in the supplier’s ability to deliver quality components consistently.

Understanding Production Capabilities and Capacity

A supplier’s value depends on their ability to deliver parts reliably. You need to assess their production capabilities to ensure they can meet your deadlines and volume requirements. Understanding their lead times, scheduling systems, and scalability is essential for a stable supply chain. A dependable manufacturer will be transparent about their production capacity and how they manage their manufacturing workflow.

What are your typical lead times for tooling and production?

Lead time directly impacts your project timeline. You need to ask for clear estimates for both tooling and part production. A reliable supplier will provide realistic timelines and explain the factors that influence them. Delays in sintered parts manufacturing often stem from process issues. Understanding these potential problems helps you evaluate a supplier’s control over their quality and manufacturing process.

Common causes for production delays include:

- Incorrect Sintering Parameters: Using the wrong temperature or time can lead to oversintering or undersintering, requiring rework.

- Surface Defects: Issues like blistering from trapped gas or sweating from impurities can cause parts to be rejected.

- Deformation: Warping and sagging during the sintered process can result in dimensional inaccuracies, leading to production holds.

A proactive manufacturer minimizes these risks through tight process control, ensuring a more predictable production schedule.

How do you manage production scheduling and capacity?

Effective scheduling is key to on-time delivery. You should ask a potential supplier how they plan and manage their production capabilities. A modern powdered metal parts manufacturer uses advanced software to optimize their workflow. These systems help them balance workloads, manage resources, and provide accurate delivery forecasts.

Common Production Planning Systems:

- Manufacturing Execution System (MES): Integrates with the factory floor for real-time production tracking.

- Materials Requirements Planning (MRP): Ensures all necessary raw materials are available for production.

- Finite Capacity Scheduling: Plans production based on the actual, finite capacity of machines and personnel.

These tools allow a manufacturer to manage complex production schedules efficiently. They demonstrate a commitment to meeting delivery promises and managing their production capabilities effectively.

What is your process for scaling production volume?

Your demand for sintered parts may change over time. You need a partner who can scale production up or down without compromising quality. Ask about their strategy for managing fluctuating volumes. A flexible supplier will have a clear process for adjusting production to meet your needs. This might involve leveraging on-demand manufacturing techniques or implementing low-volume production runs to match output with actual demand. This approach helps control costs and ensures the supplier can adapt as your business grows. A well-defined scaling process is a sign of a mature and capable manufacturing partner ready for a long-term relationship.

Verifying In-House Secondary Operations

Many sintered parts require additional steps after the initial manufacturing process. You need a partner who can manage these secondary operations efficiently. A capable manufacturer handles many of these processes in-house. This gives them greater control over the final product quality and production schedule. Understanding their capabilities is key to ensuring part compatibility and performance.

What secondary operations do you perform in-house?

A supplier with extensive in-house capabilities can streamline your production timeline. Ask for a list of the secondary operations they perform on-site. A well-equipped manufacturer can handle a variety of finishing and modification tasks. This vertical integration reduces logistical complexity and potential delays.

Common In-House Secondary Operations:

- Machining: Turning, drilling, milling, and grinding to achieve precise dimensions.

- Finishing: Deburring, honing, and shot peening for improved surface characteristics.

- Treatments: Heat treating, steam treating, and surface treatments to enhance strength or corrosion resistance.

- Assembly: Bonding or joining multiple components.

Keeping these processes under one roof gives a manufacturer direct oversight of the entire manufacturing workflow.

How do you manage quality for outsourced processes?

A supplier may need to outsource certain specialized processes, like plating. You must verify how they maintain quality control with their external partners. The primary manufacturer is always responsible for the final part. They must have a robust system for managing outsourced work. This includes defining clear output criteria and inspection standards for their vendors. For example, when plating is outsourced, your supplier should verify key attributes. They must confirm coating thickness with tools like x-ray fluorescence and test adhesion to prevent peeling or flaking.

What testing equipment do you have on-site?

On-site testing equipment allows a manufacturer to verify part properties quickly and accurately. Ask what tools they use for inspection and quality assurance. This equipment is essential for confirming that parts meet your specifications for strength and durability. A common and critical piece of equipment is a hardness tester. These devices apply a specific load to the part’s surface to measure its resistance. This data is vital for evaluating material hardness. Modern portable testers provide fast and accurate results, which helps prevent production delays. This immediate feedback loop is a sign of a mature and reliable manufacturing operation.

Investigating Supplier Reputation and Partnership

A supplier’s technical skills are only part of the equation. You need a partner with a strong reputation for reliability and collaboration. Investigating a potential supplier’s business practices gives you insight into their long-term value. A good supplier reputation is built on clear communication and consistent performance.

Who will be my primary point of contact?

A dedicated point of contact is essential for a smooth partnership. You need one person who understands your account and can resolve issues quickly. This person acts as your advocate within the manufacturer’s organization. A great account manager builds a strong relationship with you. They also manage your account’s health and address any concerns.

- Build and maintain a strong, long-lasting client relationship.

- Address customer issues in coordination with other teams.

- Monitor account health and risk indicators.

- Develop new business opportunities with your account.

This single point of contact simplifies communication and ensures accountability.

Can you provide customer references in our industry?

A supplier’s history speaks volumes about its reliability. You should always ask for customer references to verify their reputation. Speaking with past clients gives you an honest look at the supplier’s performance. This step helps you understand their professionalism and ability to meet commitments. When you contact a reference, ask about their overall satisfaction and the quality of the products they received. This feedback is crucial for evaluating a manufacturer and their reputation.

How do you ensure on-time delivery?

Consistent on-time delivery is critical for your production schedule. Ask a potential supplier how they track and maintain their delivery performance. Top-tier suppliers achieve high on-time delivery (OTD) rates. Their reputation depends on this reliability. You should expect a clear answer supported by data.

On-Time Delivery Benchmarks by Industry

Industry OTD Rate Benchmark Automotive Manufacturing 95% or higher Electronics & High-Tech Mfg. 92-96% Consumer Goods Manufacturing 90-95%

A supplier who meets or exceeds these benchmarks demonstrates a commitment to your supply chain’s stability.

Clarifying Cost and Pricing Structure for Sintered Parts

Understanding a supplier’s pricing is crucial for managing your budget and finding the best long-term value. You need to look beyond the per-unit price to see the complete financial picture. A transparent supplier will provide a detailed cost breakdown, helping you avoid unexpected expenses.

What is your complete pricing structure?

You should ask for a full breakdown of all costs. The final price of sintered components includes more than just the part itself. A reputable manufacturer will explain how various factors contribute to the total cost. This transparency helps you understand the true value you are receiving.

Key Cost Components to Discuss:

- Raw Materials: The price of metal powders and additives.

- Labor and Overhead: Includes skilled worker wages and energy for the sintering process.

- Tooling: Costs for custom molds and dies.

- Quality Control: Expenses for testing and inspection.

- Logistics: Shipping, customs, and insurance fees.

Remember that post-processing operations like coloring or sandblasting can add 20% to 35% to the total manufacturing cost.

What factors can cause price fluctuations?

Market volatility can affect your costs. You need to know what might cause the price of your sintered parts to change. The cost of key raw materials like iron and copper powders can fluctuate by over 25% in short periods. These changes are driven by global supply and demand. Ask a potential supplier how they manage these risks to maintain stable pricing. A proactive manufacturer will use strategic sourcing and inventory management to protect you from sudden price hikes.

Are there separate costs for tooling and prototyping?

Tooling is a necessary upfront investment for sintered parts manufacturing. The good news is that powder metal tooling is often more competitive than tooling for die casting or forging. You must clarify how a supplier handles these initial costs. The amortization process can vary, so ask about their specific policy.

Common tooling payment options include:

- Paying the full cost upfront.

- Spreading the cost over the first production run.

- A one-time engineering charge that covers development.

Understanding these options helps you plan your project budget effectively and assess the total partnership value.

Choosing sintered parts requires asking your potential supplier detailed questions. You must assess their quality systems, technical expertise, and sintered production reliability. A transparent and well-established supplier welcomes this scrutiny. They provide clear, confident answers about their production capabilities.

Use these questions to find a partner for your sintered production. They can deliver high-quality sintered parts consistently. This ensures the success of your sintered production and the reliability of your sintered production.

FAQ

What is powder metallurgy?

Powder metallurgy is a metal-forming process. It involves compacting metal powders in a die and then heating them in a furnace. This heating process, called sintering, bonds the particles together. The result is a solid, near-net-shape component with specific mechanical properties.

Why are sintered parts cost-effective?

The powder metallurgy process creates parts very close to their final shape. This greatly reduces material waste. It also minimizes the need for expensive secondary machining operations. These efficiencies make sintered parts a highly economical choice for high-volume production runs.

Can sintered parts be used for automotive applications?

Yes, they are ideal for the automotive industry. Many suppliers hold certifications like IATF 16949, a key standard for automotive quality management. You can find sintered components in engines, transmissions, and shock absorbers, where they provide reliable performance and durability.

How strong are sintered parts?

The final strength of a sintered part depends on its material composition and density. You can achieve excellent mechanical properties by selecting the right metal powder blend. This process allows for tailored performance, meeting the specific demands of your application.