Piston rods are essential components in industrial machinery, playing a key role in transferring force within heavy equipment to ensure smooth operation across various applications. Partnering with reliable piston rod suppliers is crucial for achieving operational efficiency and prolonging the lifespan of your machinery. For example, piston rods boast a remarkably low failure rate of only 22.8 per 1 × 10^6 hours, compared to 98.4 for valves and 43.0 for pistons and cylinders. This exceptional reliability makes them indispensable for maintaining equipment performance in demanding environments. By choosing trusted piston rod suppliers, you gain access to high-quality products designed to meet your specific requirements, whether for construction, manufacturing, or other industrial sectors.

Criteria for Selecting Piston Rod Suppliers

Quality and Durability of Products

When selecting a piston rod supplier, you should prioritize the quality and durability of their products. High-quality forged materials, such as CK45, S45C, and 42CrMo4, are essential for ensuring robust performance in hydraulic cylinder applications. Suppliers offering chrome-plated piston rods with a surface hardness of at least 850HV and a roughness of no more than 0.2 μm provide excellent wear resistance. Additionally, precise manufacturing standards, such as ISO F7 tolerance and straightness of 0.5/1000mm, guarantee smooth operation in industrial machinery.

To illustrate, consider the following features that enhance durability:

- Long style 660 bronze bushings maximize wear resistance.

- Extra-wide graphite-impregnated wear bands on pistons add support.

- Floating cushions reduce piston speed at the stroke’s end without affecting reverse movement.

- Machined headcaps made from 6061-T6 aluminum offer high strength and low weight, with anodization for corrosion resistance.

These attributes ensure that the piston rods can withstand demanding environments, making them ideal for hydraulic cylinder applications.

Industry Certifications and Standards Compliance

Certifications and compliance with industry standards validate the quality of piston rod products. For example, the BIS certification for steel used in piston pins, such as IS 11952:1986, ensures that materials meet stringent mechanical property requirements. This standard guarantees resistance to high temperatures exceeding 550°C and ensures the absence of internal or surface flaws.

When evaluating suppliers, look for adherence to globally recognized standards like ISO 9001 for quality management and ISO 14001 for environmental management. These certifications demonstrate a supplier’s commitment to delivering high-quality forged materials while maintaining sustainable practices.

Supplier Reputation and Customer Reviews

A supplier’s reputation reflects their reliability and product quality. You can assess this by reviewing customer feedback and testimonials. Positive reviews often highlight consistent product performance, timely delivery, and excellent customer service. Suppliers with a strong reputation are more likely to provide high-performance forged piston rods tailored to your specific applications.

Additionally, consider the supplier’s experience in the industry. Companies with a long history of serving industrial sectors often have the expertise to meet your hydraulic cylinder needs. Building a partnership with a reputable supplier ensures you receive products that meet your quality expectations and operational requirements.

Range of Product Offerings and Customization Options

When choosing a piston rod supplier, you should evaluate the variety of products they offer and their ability to customize solutions for your specific applications. Leading manufacturers often provide a wide range of piston rods tailored for hydraulic cylinder systems, ensuring compatibility with diverse industrial needs. Customization options, such as specific dimensions, materials, and surface treatments, allow you to optimize performance for unique operational requirements.

Suppliers with extensive product catalogs can address various applications, from construction equipment to manufacturing machinery. However, research shows that high product variety in truck manufacturing can negatively impact production quality. This highlights the importance of balancing variety with precision engineering.

In global markets, the impact of product variety on sales differs. For instance:

- In Brazil, the correlation between car variety and sales volume is stronger (ρ=0.642) than in the United States (ρ=0.330).

- This suggests that product variety plays a more significant role in certain regions, emphasizing the need for suppliers to adapt to market-specific demands.

By partnering with a supplier offering both standard and customized piston rods, you can ensure your hydraulic cylinder systems meet the highest quality standards while maintaining operational efficiency.

Global Reach and Supply Chain Reliability

A supplier’s global reach and supply chain reliability are critical factors in ensuring timely delivery and consistent product availability. Leading manufacturers leverage robust supply chains to meet the growing demand for hydraulic cylinder components across industrial sectors.

| Evidence | Description |

|---|---|

| Growth Drivers | The expanding automotive industry in Asia Pacific and Latin America drives demand for piston rods. |

| Demand Increase | Rising middle-class incomes lead to higher vehicle demand, requiring efficient supply chains. |

| Engine Design Trends | Advanced piston designs for downsized engines necessitate supplier innovation. |

Global supply chains are becoming more complex, making modern data and analytics essential for maintaining efficiency. Enhanced demand forecasting and improved operations help suppliers adapt to disruptions and ensure reliability. For example, the shift toward two-piece connecting rods in emerging markets demonstrates how suppliers innovate to meet evolving needs.

By selecting a supplier with a strong global presence, you gain access to high-quality products and a dependable supply chain, ensuring your operations remain uninterrupted.

Pricing and Value for Money

Pricing plays a significant role in evaluating piston rod suppliers, but value for money should always take precedence. A supplier offering competitive pricing without compromising on quality ensures you maximize your investment. Leading manufacturers often achieve this balance by optimizing production processes and leveraging economies of scale.

For instance, suppliers like DMR Seals and Aston Seals have demonstrated consistent value delivery by maintaining competitive pricing while ensuring high-quality standards. Gross margins and production data from 2020 to 2025 further highlight their cost-effectiveness.

When assessing pricing, consider the long-term benefits of investing in durable and reliable piston rods. High-quality components reduce maintenance costs and downtime, ultimately saving you money. By prioritizing value over cost, you can ensure your hydraulic cylinder systems perform efficiently in demanding industrial applications.

Top Piston Rod Suppliers for Heavy Machinery in 2025

MAHLE Group

MAHLE Group stands out as a global leader in the production of high-quality components for heavy machinery. With a strong focus on innovation, the company delivers piston rods designed to meet the rigorous demands of hydraulic cylinder systems. You can rely on their products for exceptional durability and performance, even in the most challenging industrial environments.

MAHLE’s commitment to research and development ensures that their piston rods incorporate cutting-edge technology. Their advanced manufacturing processes result in components with precise tolerances and superior surface finishes. This attention to detail minimizes wear and maximizes the lifespan of hydraulic cylinder systems.

The company’s global presence ensures reliable supply chain operations. MAHLE serves customers across multiple continents, providing consistent product availability and timely delivery. Their dedication to sustainability further enhances their reputation, as they prioritize eco-friendly practices in their production processes.

Tip: When selecting piston rod suppliers, consider companies like MAHLE that combine innovation, quality, and global reach to meet your operational needs.

Thyssenkrupp

Thyssenkrupp has earned its place as a trusted name among piston manufacturers. Known for its engineering excellence, the company produces piston rods that excel in strength and reliability. Their products are widely used in hydraulic cylinder applications, making them a preferred choice for industries such as construction and manufacturing.

Thyssenkrupp’s piston rods are crafted from high-grade materials, ensuring they can withstand extreme pressures and temperatures. The company adheres to stringent quality standards, including ISO certifications, to guarantee the performance and safety of its components. You can count on their products to deliver consistent results, even under heavy workloads.

The company’s extensive product portfolio includes both standard and customized solutions. This flexibility allows you to find piston rods tailored to your specific requirements. Thyssenkrupp’s global network ensures efficient distribution, reducing downtime and keeping your operations running smoothly.

- Market Insights:

- The global piston rod market is projected to grow significantly, driven by increasing demand for high-performance vehicles and heavy machinery.

- Thyssenkrupp’s focus on innovation positions them to capitalize on these trends, ensuring they remain a top choice for piston rod suppliers.

Linamar Corporation

Linamar Corporation has established itself as a leading supplier of precision-engineered components for heavy machinery. Their piston rods are renowned for their durability and compatibility with a wide range of hydraulic cylinder systems. By choosing Linamar, you gain access to products that combine quality and cost-effectiveness.

The company invests heavily in advanced manufacturing technologies, enabling them to produce piston rods with exceptional accuracy. Their components undergo rigorous testing to ensure they meet the highest standards of performance and reliability. This commitment to excellence makes Linamar a dependable partner for your industrial needs.

Linamar’s global operations span multiple regions, ensuring timely delivery and robust supply chain support. The company’s customer-centric approach includes offering technical assistance and customization options. Whether you need standard piston rods or bespoke solutions, Linamar provides the flexibility to meet your unique requirements.

Note: Linamar’s focus on precision engineering and customer satisfaction makes them a standout choice among piston manufacturers.

- Key Market Trends:

- The piston rod market is expected to grow at a steady CAGR through 2032, driven by rising demand for durable components in heavy machinery.

- Linamar’s emphasis on innovation and quality positions them to thrive in this expanding market.

Aavolyn Corp.

Aavolyn Corp. has built a reputation as one of the most reliable piston manufacturers in the industry. Their piston rods are engineered with precision to meet the demands of heavy machinery applications. You can depend on their products for consistent performance and durability, even under extreme operating conditions.

The company specializes in producing piston rods with advanced surface treatments, such as induction hardening and chrome plating. These treatments enhance wear resistance and extend the lifespan of hydraulic cylinder systems. Aavolyn also uses high-grade materials like 1045 steel and 4140 alloy steel, ensuring their products withstand high pressures and temperatures. Their commitment to quality is evident in their adherence to industry standards, including ISO 9001 certification.

Aavolyn’s product range includes both standard and custom piston rods. This flexibility allows you to find solutions tailored to your specific machinery requirements. Their customization options include varying diameters, lengths, and surface finishes, making them a versatile choice for diverse industrial applications. The company also provides technical support to help you optimize the performance of your hydraulic systems.

Tip: If you need piston rods that combine durability, precision, and customization, Aavolyn Corp. is a supplier worth considering.

WUXI BAIYE METAL TECHNOLOGY CO., LTD.

WUXI BAIYE METAL TECHNOLOGY CO., LTD., based in China, is a leading name among piston rod suppliers. Their products are widely recognized for their high-quality construction and reliability in heavy machinery applications. You can trust their piston rods to deliver exceptional performance in demanding environments.

The company employs advanced manufacturing techniques, such as CNC machining and automated polishing, to produce piston rods with precise tolerances and smooth finishes. Their chrome-plated rods feature surface hardness levels exceeding 850HV, ensuring excellent resistance to wear and corrosion. WUXI BAIYE also offers induction-hardened rods for applications requiring additional strength and durability.

Their global reach is another advantage. WUXI BAIYE exports piston rods to markets across Europe, North America, and Asia, ensuring timely delivery and consistent product availability. The company’s dedication to customer satisfaction includes offering OEM and ODM services, allowing you to customize piston rods to meet your specific needs. Their technical team provides comprehensive support, including quality inspections and detailed reports like PPAP and UT testing.

Note: WUXI BAIYE’s combination of advanced manufacturing, global presence, and customization options makes them a top choice for hydraulic cylinder components.

Tenneco Inc.

Tenneco Inc. is a global leader in the production of high-performance components for heavy machinery. Their piston rods are designed to meet the rigorous demands of hydraulic cylinder systems, making them a trusted name among piston manufacturers. You can rely on their products for durability and efficiency in industrial applications.

The company focuses on innovation, using cutting-edge materials and processes to enhance the performance of their piston rods. Tenneco’s rods feature advanced coatings, such as diamond-like carbon (DLC), which reduce friction and improve wear resistance. Their products undergo stringent testing to ensure they meet industry standards, including ISO 14001 for environmental management.

Tenneco’s extensive product portfolio includes solutions for various industries, from construction to automotive. Their global operations span multiple regions, ensuring reliable supply chain support and timely delivery. The company also prioritizes sustainability, incorporating eco-friendly practices into their manufacturing processes.

Market Insight: The demand for high-performance piston rods continues to grow, driven by advancements in hydraulic cylinder technology. Tenneco’s focus on innovation positions them as a key player in this expanding market.

Aisin Seiki Co., Ltd.

Aisin Seiki Co., Ltd. is a renowned name among piston manufacturers, offering high-quality components for heavy machinery. Their piston rods are engineered to deliver exceptional durability and precision, making them a reliable choice for hydraulic cylinder systems. You can trust their products to perform consistently under demanding conditions.

The company’s manufacturing processes emphasize advanced technology and strict quality control. Aisin Seiki uses high-grade materials like carbon steel and alloy steel to produce piston rods that resist wear and corrosion. Their products undergo rigorous testing to ensure they meet industry standards, including ISO certifications. This commitment to quality ensures that your machinery operates efficiently and reliably.

Aisin Seiki’s global presence allows them to serve customers across multiple regions. Their supply chain is designed to ensure timely delivery and consistent product availability. The company also offers customization options, enabling you to tailor piston rods to your specific requirements. Whether you need standard components or bespoke solutions, Aisin Seiki provides the flexibility to meet your needs.

Tip: Aisin Seiki’s focus on quality and innovation makes them a top choice for piston rod suppliers in the heavy machinery sector.

Max Auto Parts (China)

Max Auto Parts (China) has established itself as a trusted supplier of piston rods and other auto parts. Their products are widely recognized for their durability and precision, making them ideal for hydraulic cylinder applications. You can rely on Max Auto Parts to deliver high-performance components that meet your operational needs.

The company specializes in producing piston rods with advanced surface treatments, such as chrome plating and induction hardening. These treatments enhance wear resistance and extend the lifespan of hydraulic systems. Max Auto Parts also employs cutting-edge manufacturing techniques, including CNC machining and automated polishing, to ensure precise tolerances and smooth finishes.

Max Auto Parts exports its products to markets worldwide, including Europe, North America, and Asia. Their global reach ensures reliable supply chain operations and timely delivery. The company’s dedication to customer satisfaction includes offering OEM and ODM services, allowing you to customize piston rods to suit your specific applications. Their technical team provides comprehensive support, including quality inspections and detailed reports like PPAP and UT testing.

Note: Max Auto Parts combines advanced manufacturing, global presence, and customization options to deliver high-quality piston rods for heavy machinery.

Parker Hannifin Corporation

Parker Hannifin Corporation is a global leader in the production of high-performance components for heavy machinery. Their piston rods are designed to meet the rigorous demands of hydraulic cylinder systems, making them a trusted name among piston manufacturers. You can depend on their products for durability and efficiency in industrial applications.

The company’s manufacturing efficiency and market performance affirm its status as a top supplier. In fiscal year 2022, Parker Hannifin reported net sales of $16.01 billion, a 10.5% increase from the previous year. The operating margin expanded to 14.3%, reflecting efficient operations and strategic pricing initiatives. Earnings per share (EPS) rose by 15.6%, reaching $14.63. These figures highlight Parker Hannifin’s ability to deliver value while maintaining high-quality standards.

Parker Hannifin’s piston rods feature advanced coatings, such as diamond-like carbon (DLC), which reduce friction and improve wear resistance. Their products undergo stringent testing to ensure they meet industry standards, including ISO certifications. The company’s extensive product portfolio includes solutions for various industries, from construction to automotive. Their global operations span multiple regions, ensuring reliable supply chain support and timely delivery.

Market Insight: Parker Hannifin’s focus on innovation and efficiency positions them as a key player in the expanding piston rod market.

Bosch Rexroth

Bosch Rexroth has earned its reputation as a global leader in hydraulic technology, offering piston rods that excel in performance and reliability. If you’re looking for components that can handle demanding industrial applications, Bosch Rexroth stands out as a top choice. Their piston rods are engineered to meet the highest standards, ensuring your machinery operates efficiently and consistently.

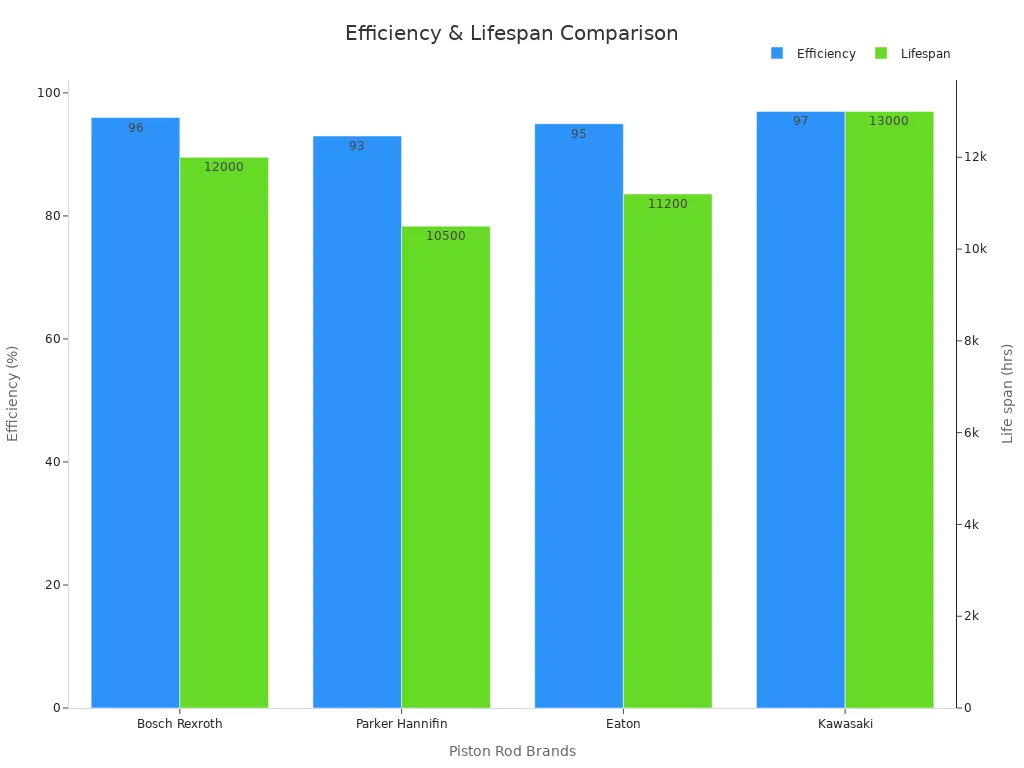

Exceptional Performance Metrics

Bosch Rexroth piston rods are designed to deliver outstanding performance under high-pressure conditions. With a pressure capacity of up to 480 bar, these components can withstand intense workloads without compromising efficiency. Their efficiency rating of 96% ensures minimal energy loss, making them a cost-effective solution for your hydraulic systems. Additionally, their average lifespan of 12,000 hours highlights their durability, reducing the need for frequent replacements.

| Brand | Pressure Capacity (bar) | Efficiency (%) | Average Lifespan (hours) | Price Range (USD) |

|---|---|---|---|---|

| Bosch Rexroth | 480 | 96 | 12,000 | $2,800–$4,200 |

| Parker Hannifin | 460 | 93 | 10,500 | $2,500–$3,800 |

| Eaton | 470 | 95 | 11,200 | $3,000–$4,000 |

| Kawasaki | 490 | 97 | 13,000 | $3,500–$5,000 |

This table compares Bosch Rexroth with other leading brands, showcasing its competitive edge in efficiency and lifespan. These metrics make Bosch Rexroth a reliable partner for industries requiring high-performance piston rods.

Advanced Manufacturing and Innovation

Bosch Rexroth employs cutting-edge manufacturing techniques to produce piston rods with precise tolerances and superior surface finishes. Their components undergo rigorous testing to ensure they meet stringent quality standards. This commitment to innovation results in products that perform consistently, even in the most challenging environments.

The company also focuses on sustainability by incorporating eco-friendly practices into its production processes. By choosing Bosch Rexroth, you not only gain access to high-quality components but also contribute to a greener future.

Global Reach and Customer Support

Bosch Rexroth’s extensive global network ensures timely delivery and reliable supply chain operations. Whether you’re based in North America, Europe, or Asia, you can count on their products to arrive on time and in excellent condition. Their customer support team provides technical assistance and customization options, allowing you to tailor piston rods to your specific needs.

This chart highlights Bosch Rexroth’s strong performance metrics compared to other leading brands. The combination of high efficiency and long lifespan makes their piston rods a valuable investment for your heavy machinery.

Tip: When selecting a piston rod supplier, prioritize companies like Bosch Rexroth that combine advanced technology, exceptional performance, and global reliability. This ensures your operations remain efficient and uninterrupted.

Tips for Evaluating and Partnering with Suppliers

Conducting Supplier Audits and Assessments

Supplier audits help you evaluate whether a supplier meets your expectations for high-quality manufacturing. Focus on key performance metrics during audits to ensure suppliers align with your operational goals.

- Quality: Assess production processes and quality management systems.

- Delivery Performance: Review on-time delivery rates and responsiveness.

- Cost: Examine pricing competitiveness and cost control measures.

- Service: Evaluate customer service and support capabilities.

- Compliance: Verify adherence to industry standards and regulations.

- Innovation: Look for evidence of continuous improvement and process enhancements.

For example, an automotive supplier audit revealed gaps in quality standards. By developing action plans and monitoring progress, the company improved product quality and reduced defects. Similarly, a consumer goods supplier evaluation increased delivery performance and cost efficiency by implementing clear criteria and providing feedback.

Tip: Regular audits ensure suppliers maintain high-quality manufacturing practices and adapt to your custom requirements.

Negotiating Contracts and Terms

Effective contract negotiation ensures you secure favorable terms while fostering a strong partnership. Begin by identifying your priorities, such as pricing, delivery schedules, and customization options.

- Prepare Thoroughly: Research market rates and supplier capabilities.

- Focus on Value: Prioritize long-term benefits over short-term cost savings.

- Include Performance Metrics: Specify quality standards, delivery timelines, and compliance requirements.

- Build Flexibility: Allow room for adjustments to accommodate evolving needs.

For instance, incorporating clauses for periodic reviews ensures suppliers maintain high-quality manufacturing standards. Custom agreements tailored to your operational needs strengthen partnerships and reduce risks.

Note: Clear communication during negotiations helps you establish mutual trust and align expectations effectively.

Building Long-Term Relationships with Suppliers

Strong supplier relationships enhance operational efficiency and ensure consistent access to high-quality manufacturing components. Focus on collaboration and mutual growth to build lasting partnerships.

- Invest in Communication: Maintain regular contact to address concerns and share updates.

- Support Innovation: Encourage suppliers to develop custom solutions for your unique requirements.

- Monitor Performance: Use audits and feedback to ensure continuous improvement.

- Recognize Contributions: Acknowledge supplier efforts to foster loyalty and commitment.

For example, suppliers who receive recognition for their innovation often prioritize delivering custom solutions. This approach strengthens relationships and ensures your supply chain remains reliable.

Tip: Long-term partnerships with suppliers who prioritize quality and innovation help you achieve operational success.

Leveraging Technology for Supplier Management

Technology plays a vital role in improving supplier management. By adopting advanced tools, you can streamline processes, reduce errors, and enhance decision-making. Modern software solutions, such as AI-powered platforms and cloud-based systems, offer significant advantages for managing suppliers effectively.

Artificial intelligence (AI) and machine learning (ML) have transformed supplier management. These technologies help you analyze large datasets, predict trends, and automate repetitive tasks. For instance:

- 54% of respondents in the Accenture Compliance Risk Study recognize AI’s potential to improve compliance.

- 93% believe AI and cloud compliance tools reduce human error and simplify operations.

Supply chain planning software also enhances efficiency. It enables you to monitor supplier performance, track inventory, and forecast demand. Despite its benefits, only 46% of manufacturers have adopted such tools. This highlights a significant opportunity for you to leverage technology and gain a competitive edge.

Real-world examples demonstrate the impact of technology. Bulgari, a luxury brand, doubled its cost savings and profits within a year of using Ivalua’s supplier management platform. Another user, Reto Rietmann, managed contracts worth a billion Euros within two months of implementing Ivalua’s S2C module. These success stories show how technology can revolutionize supplier management.

Adopting these tools not only improves efficiency but also strengthens supplier relationships. Automated systems ensure timely communication and accurate data sharing, fostering trust and collaboration. By leveraging technology, you can optimize your supply chain, reduce costs, and achieve long-term success.

Tip: Start exploring AI-driven platforms and supply chain software to unlock the full potential of supplier management. These tools can help you stay ahead in today’s competitive market.

Choosing the right piston rod supplier ensures your heavy machinery operates efficiently and lasts longer. Suppliers like Bosch Rexroth, MAHLE Group, and Max Auto Parts excel in quality, innovation, and global reliability. Their products reduce wear, enhance durability, and minimize downtime.

- Key Benefits:

- Pneumatic systems perform better with proper components and maintenance, avoiding costly downtime.

- Electric actuators offer longevity and easier maintenance, even under seal failure.

Evaluate suppliers based on your needs. Prioritize quality and reliability. Build strong partnerships to secure consistent performance and long-term success.

Tip: A reliable supplier safeguards your operations and boosts productivity.

FAQ

What are piston rods, and why are they important in heavy machinery?

Piston rods transfer force from hydraulic or pneumatic cylinders to the machinery they power. They ensure smooth operation and durability in industrial applications. High-quality piston rods reduce wear, improve efficiency, and extend the lifespan of your equipment.

How do I know if a piston rod supplier meets quality standards?

Look for certifications like ISO 9001 and ISO 14001. These indicate adherence to global quality and environmental standards. Check for customer reviews and technical reports, such as PPAP or UT testing, to verify product reliability.

Can piston rods be customized for specific applications?

Yes, many suppliers offer customization options. You can request specific dimensions, materials, and surface treatments like chrome plating or induction hardening. Customization ensures the piston rods meet your machinery’s unique operational requirements.

What factors affect the lifespan of a piston rod?

Material quality, surface treatments, and operating conditions play key roles. Chrome plating and induction hardening enhance wear resistance. Proper maintenance, such as regular lubrication and inspections, also extends the lifespan of piston rods.

Why is global reach important when choosing a piston rod supplier?

Global reach ensures timely delivery and consistent product availability, even during supply chain disruptions. Suppliers with international operations can meet your needs efficiently, regardless of your location.

Tip: Choose suppliers with a strong global presence to avoid delays and maintain operational efficiency.