The powdered metal process is an innovative manufacturing technique used to create strong, complex metal parts. This method transforms fine metal powder into a solid, durable component. The process begins by compressing the powder into a desired shape, which is then heated below its melting point to bond the particles together. This highly efficient method is gaining popularity for making precise parts.

- The global powder metallurgy market is projected to grow from USD 2.96 billion in 2024 to USD 10.19 billion by 2033.

What Is Powder Metallurgy?

Powder metallurgy is a cutting-edge manufacturing method. You start with fine metal powders and transform them into strong, solid parts. This technique allows for the creation of complex shapes with incredible precision. It offers a unique alternative to traditional metalworking.

Defining a Net-Shape Manufacturing Process

You can think of powder metallurgy as a “net-shape” process. This term means the part comes out of the initial mold very close to its final, or “net,” shape. It requires little to no extra machining or finishing work.

Imagine baking a cookie in a detailed cookie cutter. The cookie comes out in the final shape you want. A net-shape process works similarly for metal parts, saving time and effort.

This is a major advantage. In fact, you might be surprised to learn that 65-70% of all parts produced through powder metallurgy are ready to use without any secondary machining. This makes the entire production cycle faster and more streamlined.

The Core Principle: Compaction and Sintering

The process works through two main steps: compaction and sintering.

First, the metal powder is placed into a precision die. Then, the powder metal compaction stage begins. This step uses massive pressure to press the powder together into a solid, but fragile, part called a “green part.” The pressures used are immense.

- Typical pressures for powder metal compaction range from 10 to 50 tons per square inch.

Next, you take the green part to the sintering furnace. Here, it is heated to a high temperature, but always below the metal’s melting point. This heat causes the individual powder particles to bond and fuse together, creating a strong, dense final part. For example, iron parts are typically sintered in a range of 2020-2100°F (1120-1150°C) to achieve their final strength.

Material and Cost Efficiency Benefits

The powdered metal process is known for its outstanding material and cost efficiency. Traditional manufacturing often involves “subtractive” methods. You start with a large block of metal and cut away material to get your final shape, creating a lot of waste.

This process is different. It is an “additive” method where you only use the material needed for the part itself. This approach dramatically reduces scrap metal waste, often by over 97% compared to machining. Less waste directly translates to lower material costs, making it an extremely economical choice for producing parts in large quantities.

The Three Core Steps of the Powdered Metal Process

The entire powdered metal process unfolds in three distinct and crucial stages. You can think of it as a journey from loose dust to a solid, functional component. Each step builds upon the last to create a final part with remarkable strength and precision. Let’s explore how you transform raw powder into a durable product.

Step 1: Creating the Metal Powder

Everything begins with the primary ingredient: the metal powder itself. The quality and characteristics of this powder directly impact the final part’s performance. Manufacturers create this special metal powder using several sophisticated methods. The choice of method depends on the type of metal and the desired properties.

- Atomization: This is the most widely used technique. You start by melting metal into a liquid state. Then, you use high-energy jets of gas or water to blast the molten stream apart. This action creates tiny droplets that cool and solidify into powder particles. Atomization is versatile and works for many materials, including iron, steel alloys, bronze, and aluminum.

- Solid-State Reduction: This is an older process. You crush metal ore and mix it with carbon. You then heat this mixture in a furnace. The heat reduces oxygen and carbon, leaving behind a “sponge” metal cake. This cake is then crushed and sifted to create the final powder.

- Electrolysis: You can use this method to produce very pure and dense metal powders. It involves passing an electric current through a special chemical solution, or electrolyte. This causes the metal to deposit in a spongy or powdery form. Because it uses a lot of energy, you typically reserve this process for high-value metals like high-conductivity copper.

- Chemical Methods: These processes use controlled chemical reactions to produce powder. They include techniques like oxide reduction and precipitation from solutions. These methods give you excellent control over particle size and purity, making them ideal for specialty applications in electronics and high-purity components.

The powder metallurgy industry relies on these techniques to produce a consistent and reliable raw material.

Step 2: Compaction and Green Part Formation

Once you have the right powder, the next step is to shape it. This is where you use immense pressure to form the part. The process of powder metal compaction transforms the loose powder into a solid, but still fragile, object called a “green part.”

You start by filling a precision die cavity with a specific amount of powder. Then, a press applies extreme force. This metal powder pressing action forces the individual particles into tight contact, eliminating most of the air between them. Different types of presses handle this job:

- Mechanical Presses: These are fast and excellent for high-volume production of smaller, simpler parts.

- Hydraulic Presses: These offer greater pressure control and are ideal for larger or more complex multi-level parts.

- Electric Presses: These modern presses combine speed with precise control, offering high efficiency and accuracy.

What is a “Green Part”? The resulting green part holds its shape but is not yet strong. It has a density that is only a fraction of the final part. For example, a green part might have a density that is roughly 56% of the final sintered part’s density. You must handle it carefully before it moves to the final step.

This stage of powder metal compaction is critical for establishing the part’s final geometry and density. The precision of the metal powder pressing equipment ensures every part is nearly identical.

Step 3: Sintering for Final Strength

The final step is sintering, which gives the part its durability and strength. You take the fragile green part and place it in a special furnace with a controlled atmosphere. Here, you heat the part to a very high temperature, typically around 70-90% of the metal’s melting point.

The part never actually melts. Instead, the intense heat causes the individual powder particles to fuse and bond together on a molecular level. This process, called solid-state diffusion, reduces the internal pores and dramatically increases the part’s density and strength.

The sintering temperature has a huge impact on the final mechanical properties. Higher temperatures create stronger bonds and a denser structure. Research clearly shows this connection:

| Sintering Temperature | Ultimate Strength (MPa) |

|---|---|

| 1250 °C (2282 °F) | 400 ± 20 |

| 1350 °C (2462 °F) | 700 ± 20 |

As you can see, a relatively small increase in temperature can lead to a significant boost in strength. This happens because the higher heat allows for clearer bond formation between particles, resulting in a tougher, more reliable final component ready for real-world applications.

A Deeper Look at Metal Powder Production

The quality of any powdered metal part begins with its core ingredient: the powder itself. The process of making metal powder is highly scientific. You must carefully control it to get particles with the right size, shape, and purity for the job. Let’s explore the primary methods manufacturers use.

Atomization: The Most Common Method

Atomization is the most popular way to create metal powder. You start by melting the metal into a liquid. Then, you blast the molten stream with a high-pressure jet of gas or water. This powerful blast breaks the liquid metal into tiny droplets, which cool and solidify into powder. The two main types, water and gas atomization, produce different results.

| Parameter | Water Atomization | Gas Atomization |

|---|---|---|

| Particle Shape | Irregular (flakes or angles) | Spherical or nearly spherical |

| Particle Size Distribution | Wide, low proportion of fine powder | Narrow, high proportion of fine powder |

| Cooling Rate | Faster | Slower |

| Kinetic Energy of Medium | Strong impact force (water) | Lower kinetic energy (gas) |

The faster cooling from water atomization creates irregular particles. These rough shapes lock together well during compaction. The slower cooling from gas atomization results in smooth, spherical particles that flow easily into complex molds.

Chemical Reduction and Electrolysis

Other methods for making powder metal are used for specific needs.

- Chemical Reduction involves heating crushed metal ore with a reducing agent like carbon. This removes oxygen and leaves a solid “sponge” of metal, which you then crush into powder.

- Electrolysis uses an electric current in a chemical solution to produce very pure metal powders. You often reserve this energy-intensive process for high-value metals like copper.

These chemical-based processes give you excellent control over powder purity, making them ideal for specialized applications where material integrity is the top priority.

Common Materials Used for Metal Powder

You can make a wide variety of parts because so many different metals are available in powder form. Each material offers unique properties for different applications. Common choices include:

- Iron and Steel Alloys: Used for their strength, durability, and cost-effectiveness in automotive and structural parts.

- Stainless Steel: Chosen for its excellent corrosion resistance in medical and food-grade applications.

- Bronze: Valued for making self-lubricating bearings.

- Aluminum: Selected for its lightweight properties in aerospace and consumer electronics.

- Titanium: Used for its high strength-to-weight ratio and biocompatibility in medical implants.

Key Advantages of Powder Metallurgy

You can gain significant benefits by choosing powder metallurgy for your manufacturing needs. This process offers unique advantages in design freedom, material savings, and product consistency. It stands out as a superior choice for many applications.

Capability for Complex Geometries

You can create incredibly complex shapes with powder metallurgy that are difficult or too expensive to produce with other methods. The process allows you to combine multiple features into a single component, reducing the need for assembly. This design freedom opens up new possibilities for innovation. For example, you can produce:

- Helical gears with high core densities.

- Parts with blind corners, which removes the need for extra cutting.

- Compound gear assemblies that include cams or ratchets in one step.

- True involute gear forms, which are easier to make with this method.

This ability to form intricate designs makes powder metallurgy a powerful tool for creating advanced parts.

Exceptional Material Utilization

This process offers outstanding material efficiency. Traditional machining is a “subtractive” process where you cut away material from a larger block, creating significant waste. Powder metallurgy is an “additive” process. You only use the powder needed to form the final shape.

This approach dramatically reduces waste. The scrap rate for this process is typically around 3%, while CNC machining can waste up to 50% of the raw material.

Less waste means lower material costs. This makes the process a very economical choice, especially for high-volume production runs.

High Dimensional Accuracy and Consistency

You can achieve excellent precision and consistent quality with this manufacturing method. The use of durable, reusable tooling ensures that every component is nearly identical. This repeatability is crucial for applications where parts must fit together perfectly.

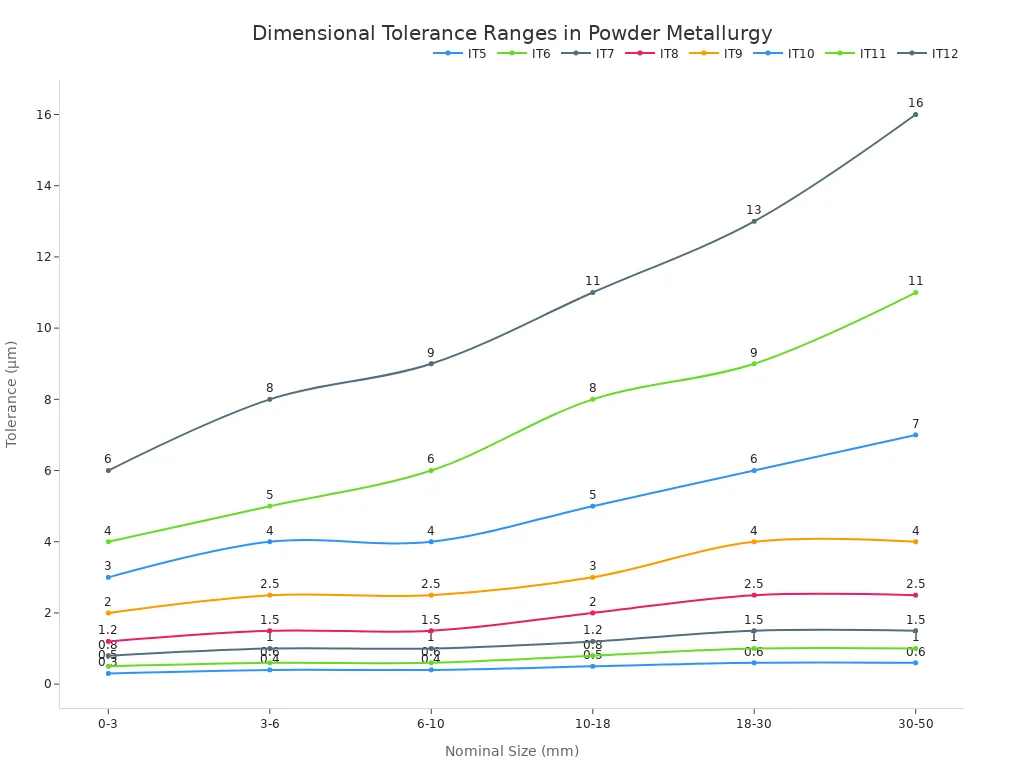

After sintering, components typically achieve a dimensional accuracy of IT8 to IT9. You can improve this even further with a secondary sizing operation, reaching tolerances as tight as IT6-IT7. The chart below shows the achievable tolerances for different part sizes and IT grades.

This high level of control ensures your final parts meet strict engineering specifications every time.

Cost-Effectiveness in High-Volume Production

You will find that powder metallurgy is an extremely economical choice when you need to produce a large number of parts. The process requires a significant initial investment in tooling, such as the precision dies used for compaction. This upfront cost can seem high. However, the real savings appear when you scale up production.

The cost of the tooling is spread across thousands or even millions of components. This distribution dramatically lowers the price of each individual part. The high speed of automated presses further reduces labor costs and production time, making the entire operation highly efficient for large orders.

When you are deciding on a manufacturing method, you should consider both the part’s complexity and the total production volume. Different processes become cost-effective at different scales.

| Method | Production Volume | Part Complexity | Cost-Effectiveness |

|---|---|---|---|

| Powder Metallurgy (PM) | Medium to High | Simple | Highly economical |

| Metal Injection Molding (MIM) | High | Complex | Cost-effective due to tooling amortization |

As you can see, PM is a strong choice for simpler parts in high volumes. For lower production runs, other methods might be more suitable, especially if you want to keep initial tooling costs down.

| Method | Production Volume | Part Complexity | Cost-Effectiveness |

|---|---|---|---|

| Investment Casting | Low to Medium | Moderately Complex | More cost-effective, especially when minimizing tooling costs is a priority |

The key takeaway is simple: the more parts you produce using this method, the lower your cost-per-part becomes. This makes it an ideal solution for industries like automotive and appliance manufacturing that rely on mass production.

This scaling advantage is a primary reason why so many industries turn to this process for reliable and affordable components.

Real-World Applications: Where You Find Powdered Metal Parts

You might be surprised to learn how often you interact with powder metal parts in your daily life. This manufacturing process is essential for creating durable and precise components across many industries. From the car you drive to the appliances in your home, these parts are everywhere.

Automotive Components

The automotive industry is the largest user of powder metallurgy. You can find these components in critical areas of a vehicle, especially within the engine and transmission. Manufacturers choose this process to produce strong, reliable parts that can handle high stress. Common examples include:

- Crankshaft sprockets and timing pulleys

- Oil pump rotors

- Valve guides

- Connecting rod and crankshaft bearings

- Water pump pulleys

These essential parts help your car run smoothly and efficiently. The ability to create complex shapes makes this method perfect for the intricate designs needed in modern engines.

Industrial Machinery and Power Tools

You will also find powder metal parts in heavy-duty equipment and the power tools in your garage. The process is ideal for making strong gears that transfer power. Different types of gears are used for specific jobs.

- Spur gears have straight teeth and are used in power tools.

- Helical gears have angled teeth for smoother, quieter operation in industrial pumps.

- Bevel gears change the direction of power, which you can find in conveyor systems.

The strength and precision of these gears are critical. They ensure that industrial machines operate reliably under constant use, making them a backbone of the manufacturing sector.

Appliances and Consumer Products

Your home appliances rely on powder metallurgy to function correctly. A single washing machine can contain 10 to 15 different powder metal parts, while a refrigerator compressor has about 5 to 10. In refrigerators, you can find pistons and connecting rods that help compress the refrigerant. In washing machines, these components include:

- Gears and bushings for the transmission

- Clutch assemblies

- Hinge components for the door

These small but mighty parts provide the durability needed for appliances to last for years, handling daily wear and tear with ease.

Powder Metallurgy vs. Traditional Manufacturing

You need to select the right manufacturing method for your project. Understanding how powder metallurgy compares to traditional methods like casting and forging helps you make the best choice. Each process has unique strengths.

Comparison with Casting

Casting involves pouring liquid metal into a mold and letting it cool. While useful, it differs from powder metallurgy in key areas. You can see that powder metallurgy offers better material use and precision.

| Feature | Powder Metallurgy | Casting |

|---|---|---|

| Material Use | Very high (up to 97%) | Lower (material lost in sprues) |

| Accuracy | Excellent, near-final shape | Good, but often needs machining |

| Surface Finish | Good and consistent | Can be rough and require finishing |

Casting can create very large parts, like engine blocks. However, you gain superior control over the final shape and waste less material with powder metallurgy.

Comparison with Forging

Forging shapes metal by hammering or pressing it. This process creates exceptionally strong parts. Forged components generally have better mechanical properties than powdered metal parts. Forging produces parts with higher strength and much longer fatigue life.

Forged parts have higher ductility and impact strength. You should not use powdered metal parts for applications that demand the absolute highest strength.

| Property | Forged Parts | Powder Metal Parts |

|---|---|---|

| Yield Strength | 16% higher | Lower |

| Ultimate Tensile Strength | 8% higher | Lower |

| Fatigue Life (Cycles) | 1E20 | 1E16 |

When to Choose the Powdered Metal Process

You should choose the powdered metal process when your project meets certain criteria. This method shines in specific situations where its advantages provide the most value.

Consider this process if you need:

- Complex Shapes: To make intricate parts that are difficult or costly to machine.

- High Volume: To produce thousands or millions of identical parts cost-effectively.

- Material Efficiency: To minimize scrap and reduce material costs.

- Good Tolerances: To create parts that are very close to their final dimensions right out of the mold.

This approach is ideal for producing items like gears, bearings, and automotive components in large quantities.

Quality Control and Secondary Operations

Creating a part is just the beginning. You must also ensure its quality and prepare it for its final job. This is where quality control and secondary operations become essential.

Ensuring Part Integrity with Advanced Testing

You can have confidence in your components because the industry follows strict rules to guarantee quality. Manufacturers rely on detailed standards to test and verify every part.

A primary guide is MPIF Standard 35. This standard sets clear rules for the chemical makeup, strength, and hardness of powdered metal materials. It ensures every part meets a high benchmark for quality.

Following these guidelines is a key part of the quality control process. This commitment to quality is a hallmark of advanced powder metallurgy, giving you parts that perform reliably.

Post-Sintering Finishing Options

After sintering, you can use several finishing operations to enhance a part’s properties or dimensions. These steps improve the final quality and tailor the component for a specific application. Common options include mechanical processes and surface treatments.

You can choose from several operations to achieve different goals.

| Secondary Operation | Main Goal |

|---|---|

| Sizing | Improves dimensional accuracy to meet tight tolerances. |

| Coining | Increases density and refines the surface finish. |

| Impregnation | Fills pores with oil for self-lubrication or resin to seal the part. |

You can also apply various surface treatments to boost performance. For example, you can use steam treatment to harden an iron part’s surface and improve its corrosion resistance. Plating adds a thin layer of another metal, like zinc or nickel, for even greater protection. These finishing touches are vital for the overall quality and durability of powder metallurgy components.

The powdered metal process offers you a powerful manufacturing solution. You can transform fine metal powder into durable, precise powder metal parts with remarkable efficiency. This method provides design freedom and high material efficiency for complex parts.

Recent innovations show this method can boost production speeds by 9x and cut costs by 80%.

Future trends like AI and advanced sintering promise even better parts. Understanding how metal powder becomes a final product helps you choose the right process for your parts.

FAQ

What makes powder metal parts so strong?

You get strong parts from the sintering step. The process heats a compressed “green part” below its melting point. This intense heat fuses the metal particles together on a molecular level, creating a dense and durable final component ready for tough jobs.

Are powder metal parts self-lubricating?

Yes, you can make them self-lubricating. A secondary process called oil impregnation fills the part’s natural pores with oil. This creates a built-in lubrication system, which is perfect for components like bearings that need to operate smoothly with low friction.

How do you ensure every part is high quality?

We guarantee quality by following strict industry rules like MPIF Standard 35. You can trust our parts because we use advanced equipment. Our team uses projectors, hardness testers, and metallography analyzers to verify every component meets precise specifications. ✅

Is the powdered metal process expensive?

This process is very cost-effective for high-volume orders. While initial tooling costs exist, the price per part drops significantly as you produce more. This makes it an ideal and economical choice for industries like automotive that require thousands of identical parts.