Hard chrome plated steel bars set the standard for durability in industrial environments. Hard chrome plated steel bars resist corrosion and maintain high performance even in demanding conditions. Many factories rely on the strength of hard chrome plated steel bars to keep industrial machinery running smoothly. The unique surface of hard chrome plated steel bars reduces friction, which boosts performance and extends the life of machinery. Hard chrome plated steel bars remain the material of choice when durability and reliability matter most in industrial applications. Powerful machines depend on hard chrome plated steel bars that deliver consistent performance and long-lasting durability.

Key Properties of Hard Chrome Plated Steel Bars in Industrial Applications

Corrosion Resistance and Surface Protection

Chrome plating provides outstanding corrosion resistance for steel bars used in industrial environments. The dense, non-porous layer formed by chrome plating acts as a barrier, shielding the underlying steel from moisture, chemicals, and harsh operating conditions. Scientific studies have shown that coated steel bars experience much less corrosion than uncoated ones. For example, when exposed to high temperatures and corrosive salt environments, bare steel bars lost significant thickness and gained more weight due to corrosion. In contrast, chrome plated steel bars showed only minor changes in thickness and much lower weight gain, proving their superior corrosion resistance. This protection ensures that machinery and equipment maintain their structural integrity and performance over time. Chrome plating also prevents rust and pitting, which can lead to premature failure in industrial applications. The result is a longer service life and reduced maintenance costs for critical components.

Exceptional Hardness and Wear Resistance

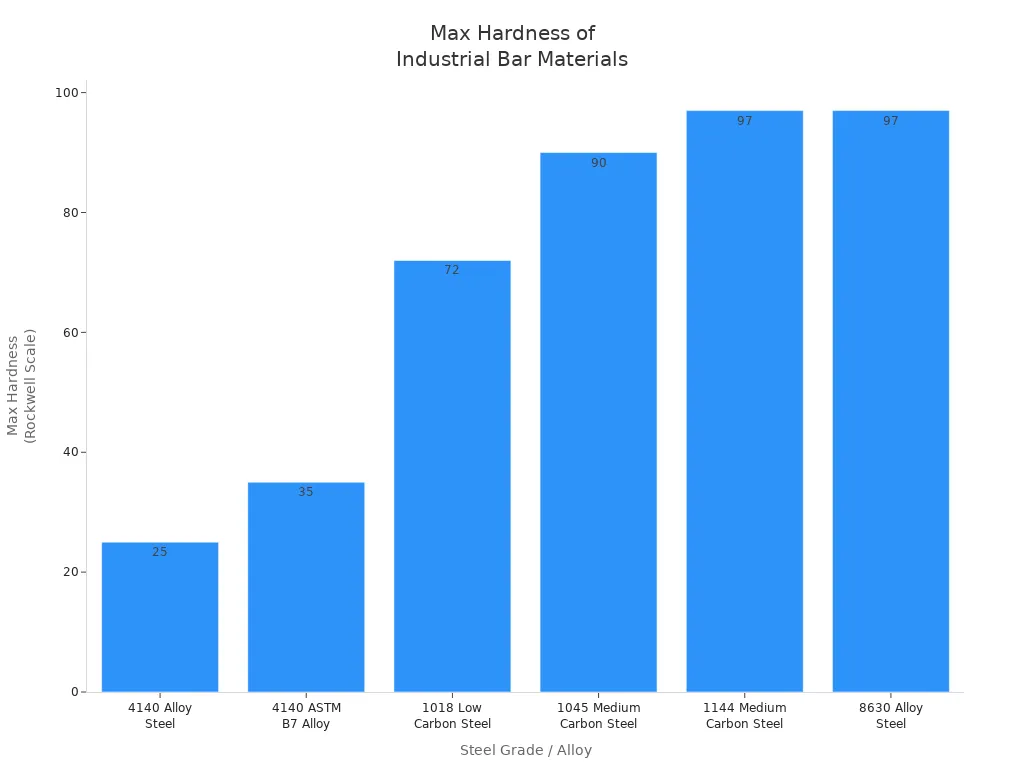

Chrome plating delivers enhanced hardness to steel bars, making them ideal for demanding industrial uses. The process increases the surface hardness far beyond that of most base steels. For reference, common industrial steels like 4140 alloy reach a maximum Rockwell C hardness of C25, while hard chrome plating can push surface hardness values much higher.

This enhanced hardness translates directly into improved wear resistance. Industry tests show that hard chrome plated steel bars can last two to ten times longer than uncoated steel in abrasive or high-contact environments. The chrome plating process uses precise control of thickness and chemistry to optimize durability. In wear resistance tests, chrome plated steel bars maintained their integrity even under sliding wear and corrosive conditions. The surface resists adhesive and abrasive wear, which are common in hydraulic cylinders, automotive parts, and mining equipment. This level of wear resistance means less downtime and fewer replacements, which is critical for industrial operations.

Low Friction and Smooth Operation

Chrome plating creates a superior surface finish that reduces friction between moving parts. The smooth, mirror-like surface of chrome plated steel bars lowers the coefficient of friction to about 0.1-0.2, much lower than untreated steel. For comparison, static friction coefficients for chrome on steel are around 0.19, while steel on steel measures at 0.31. This reduction in friction leads to smoother operation and less energy loss in industrial machinery.

A low friction surface not only improves efficiency but also minimizes sticking and deformation during operation.

The superior surface finish of chrome plating helps prevent sticking in molding and ejection processes, saving production costs and reducing waste. Industrial equipment benefits from this property through lower maintenance needs and increased operational efficiency. The combination of low friction and a superior surface finish ensures that chrome plated steel bars deliver reliable performance in even the most demanding industrial applications.

High Load-Bearing Strength

Industrial equipment often faces extreme forces and heavy loads. Hard chrome plated steel bars deliver the high strength needed to support these demanding applications. Engineers choose these bars for their ability to withstand intense pressure without bending or breaking. The unique combination of a tough steel core and a hard chrome surface gives these bars a distinct advantage in load-bearing roles.

Note: The high strength of hard chrome plated steel bars ensures reliable performance in critical machinery, even under the most challenging conditions.

Many industries rely on these steel bars for their superior load capacity. Construction equipment, hydraulic presses, and heavy-duty vehicles all require components that can handle significant weight and repeated impacts. Hard chrome plated steel bars meet these needs by offering both surface hardness and core toughness.

- Induction hardened chrome plated steel bars receive a special heat treatment. This process creates a tougher, more resilient surface, which leads to enhanced durability and superior wear resistance.

- These steel bars excel in high-stress and impact environments, such as construction machinery, automotive parts, and industrial equipment.

- Standard chrome plated bars provide excellent corrosion resistance and a smooth surface finish. However, induction hardened variants offer even greater impact resistance, making them ideal for the most demanding applications.

- Compared to other steel bar types, such as medium-carbon, high-carbon, alloy, or stainless, hard chrome plated steel bars stand out. They combine corrosion resistance, surface hardness, and wear resistance in a single product.

- The combination of hard chrome plating and induction hardening extends the lifespan and performance of steel bars. These bars outperform typical carbon or alloy steel bars when exposed to high-stress or impact conditions.

A table below highlights the advantages of hard chrome plated steel bars in high load-bearing applications:

| Steel Bar Type | Corrosion Resistance | Surface Hardness | Wear Resistance | Impact Resistance | High Strength |

|---|---|---|---|---|---|

| Hard Chrome Plated Steel Bar | Excellent | High | High | Good | Yes |

| Induction Hardened Chrome Plated | Excellent | Very High | Very High | Excellent | Yes |

| Standard Alloy Steel Bar | Moderate | Moderate | Moderate | Moderate | Yes |

| Stainless Steel Bar | Excellent | Moderate | Moderate | Moderate | Yes |

This table shows that induction hardened chrome plated steel bars offer the best combination of high strength, impact resistance, and durability. Their ability to support heavy loads makes them essential in industries where safety and reliability matter most.

Engineers trust hard chrome plated steel bars to maintain their shape and function under pressure. These bars resist deformation and fatigue, even after years of service. Their high strength and robust construction help prevent equipment failure and costly downtime.

The Role of Chrome Plating in Precision Chrome-Plated Steel Bars

Chrome Plating Process for Industrial Use

Precision chrome-plated steel bars rely on a carefully controlled chrome plating process to achieve their outstanding properties. Manufacturers begin by selecting high-quality cold drawn seamless steel tubes. They cut and machine these tubes to exact dimensions. Heat treatment follows, which improves the hardness and mechanical strength of the steel. Grinding and polishing remove imperfections and prepare the surface for chrome plating.

The chrome plating process uses electroplating. The bars rotate slowly as they pass through multiple circular anodes in a chromium electrolyte bath. This method ensures even chrome plating on every side and along the entire length of the bar. The process deposits a corrosion-resistant and wear-resistant layer, which is essential for industrial applications. Continuous quality control checks for surface defects, dimensional accuracy, and plating thickness at every stage.

Routine chemical analysis and bath maintenance help maintain consistent chrome plating quality and prevent defects.

Final inspection and packaging ensure that only bars meeting strict standards reach customers.

Key Steps in Chrome Plating:

- Selection of raw materials

- Cutting and shaping

- Heat treatment

- Grinding and polishing

- Chrome plating

- Quality control

- Final inspection and packaging

Achieving Consistent Quality and Thickness

Precision chrome-plated steel bars must meet strict industry standards for chrome plating thickness and uniformity. The advanced plating process, which rotates the steel bars through multiple anodes, prevents thickness variance and eliminates unplated ends or bulges. This technique achieves a consistent chrome plating thickness, which is critical for durability and performance.

| Parameter | Specification / Standard |

|---|---|

| Chrome Plating Thickness | Minimum 0.001″ per side (typical 0.0005″-0.002″) |

| Uniformity Process | Rotating bars through multiple anodes |

| Surface Hardness | 67 to 72 HRC |

| Surface Finish | 6 to 16 Ra (standard 6 to 12 Ra) |

| Corrosion Resistance Tests | 1000+ hours (ASTM B-117), ISO 10289 |

| Application Examples | Hydraulic cylinders, automotive, construction |

Consistent chrome plating thickness directly impacts the performance and longevity of chrome plated steel. Data shows that uniform thickness improves corrosion resistance, adhesion strength, and lifespan. For example, salt spray tests demonstrate that bars with controlled chrome plating thickness can resist corrosion for 500 to 2000 hours. Strong adhesion and uniformity also prevent premature failure.

Maintaining Surface Integrity and Longevity

Precision chrome-plated steel bars deliver a superior surface finish that resists wear and corrosion. The chrome plating process creates a hard, smooth layer that protects the steel core. Non-destructive testing methods, such as ultrasonic and magnetic particle inspection, detect surface and internal defects without damaging the chrome plating. Measurement techniques like X-ray fluorescence and microhardness testing verify composition, hardness, and plating thickness.

Consistent process control and regular inspection ensure that each bar maintains its surface integrity and delivers long-term performance.

The combination of a superior surface finish and robust chrome plating extends the longevity of precision chrome-plated steel bars. These bars maintain their properties even after years of heavy use in demanding environments. Their durability and longevity make them the preferred choice for critical industrial applications.

Industrial Applications of Hard Chrome Plated Steel Bars

Hydraulic and Pneumatic Systems

Hydraulic and pneumatic systems rely on hard chrome plated steel bars for critical components such as piston rods. These bars deliver high performance in industrial settings, including agricultural machinery, cranes, and production equipment. The table below highlights key specifications and performance improvements:

| Component/Application | Hydraulic and Pneumatic Cylinders (Piston Rods) |

|---|---|

| Common Uses | Agricultural machinery, production equipment, cranes, garbage compactors, lifters |

| Steel Materials | CK45, 4140, 42CrMo4, SAE1045, 40Cr, 20MnV6, SAE10V45, ST52 |

| Chrome Layer Thickness | Minimum 15 μm (<20 mm); 20 μm (≥20 mm) |

| Surface Roughness | Max Ra 0.2 μm |

| Surface Hardness | Min 800 HV |

| Diameter Tolerance | ISO f7 to f8 |

| Straightness | 0.2–0.3 mm per 1000 mm |

| Performance Improvements | Enhanced wear and corrosion resistance, smooth surface, high yield strength, reduced friction, improved hardness, uniform quality |

These properties ensure durability and smooth operation under high stress and harsh conditions, making chrome plating essential for these applications.

Automotive and Heavy Machinery

Automotive and heavy machinery sectors use hard chrome plated steel bars in many applications. These bars improve durability and reduce maintenance needs.

- Surface hardness reaches 50-60 HRC, confirmed by Rockwell Hardness tests.

- Chrome plating provides excellent corrosion protection, exceeding AMS 2460 standards.

- Automotive applications include shock absorbers and piston rods, which account for a significant portion of demand.

- Induction hardened chrome plated bars withstand extreme conditions in construction equipment, reducing downtime.

- The polished surface finish lowers friction and seal wear, minimizing leakage and extending service intervals.

- Technological advancements in chrome plating and induction hardening increase product quality and service life.

- Comparative studies show these bars outperform alternative coatings in maintaining seal integrity and reducing wear.

These advantages make hard chrome plated steel bars a preferred choice for industrial machinery and heavy-duty vehicles.

Aerospace and High-Performance Equipment

Aerospace and high-performance equipment require materials that can withstand extreme environments. Chrome plating on steel bars provides superior corrosion resistance, wear protection, and dimensional precision. These properties support applications of chrome plated steel rods in aerospace, where reliability and extended service life are critical. Technological advancements in chrome plating have improved surface hardness and smoothness, meeting the strict demands of high-performance machinery. Experimental results show that specific plating parameters yield the highest wear resistance and microhardness, verified by pin-on-disc and SEM analysis. The aerospace industry values these bars for their ability to maintain performance under high pressure and harsh conditions, reducing maintenance costs and supporting market growth.

Problems Solved by Hard Chrome Plated Steel Bars in Industrial Environments

Preventing Premature Wear and Equipment Failure

Industrial machinery faces constant threats from wear, corrosion, abrasion, and friction. These issues often lead to early equipment failure, causing costly interruptions. Hard chrome plated steel bars address these challenges by providing a tough, protective surface that resists damage. The high hardness and wear resistance of the chrome layer reduce surface wear and abrasion, even in harsh environments. Corrosion resistance shields components from chemicals and moisture, which are common in many industrial applications.

Many industries, such as automotive, aerospace, oil and gas, and marine, rely on these bars to keep equipment running smoothly. Hydraulic cylinders, pistons, valves, drill pipes, rollers, shafts, engine parts, crank shafts, and shock absorber rods all benefit from the enhanced durability of hard chrome plating. The coating also prevents surface pitting, burning, and localized heating damage, which are frequent causes of failure in moving parts. By maintaining dimensional stability under stress, these steel bars help prevent breakdowns and extend the longevity of critical machinery.

Tip: Proper surface preparation and plating techniques ensure a defect-free chrome layer, further reducing the risk of equipment failure.

Reducing Maintenance and Downtime

Maintenance and downtime can drain resources and disrupt production schedules. Hard chrome plated steel bars help minimize these issues by extending the service life of key components. Reports from leading equipment manufacturers show that chrome plating on steel cylinder rods can double the service life of hydraulic cylinders. Some mining machines with chrome-plated rods have operated for over 15,000 hours before needing major repairs. This remarkable durability leads to fewer emergency repairs and lower spare parts costs.

The hard chrome surface reduces wear on seals and prevents oil leaks, which keeps hydraulic systems running smoothly. Laboratory and field studies confirm that rods with advanced chrome coatings last over three times longer than traditional rods. Companies in mining and construction report fewer breakdowns and less maintenance time, which translates to reduced repair costs and improved operational efficiency.

A table below summarizes the impact of hard chrome plated steel bars on maintenance and downtime:

| Benefit | Impact on Operations |

|---|---|

| Extended component life | Fewer replacements needed |

| Reduced seal wear | Less frequent maintenance |

| Fewer oil leaks | Improved system reliability |

| Lower spare parts costs | Cost savings |

| Longer service intervals | Less downtime |

Hard chrome plating can be reapplied multiple times on the same equipment, further reducing downtime and replacement costs. This process supports continuous operation and helps companies maintain productivity.

Enhancing Equipment Efficiency and Service Life

Equipment efficiency and service life are critical for industrial success. Advances in coating technologies and surface finishing techniques have improved the performance of hard chrome plated steel bars in demanding applications. Enhanced durability and improved adhesion between the chrome layer and steel substrate extend operational life. High-precision grinding and polishing deliver smoother surfaces and tighter tolerances, which increase product value and reliability.

Automation in manufacturing reduces production time and costs, making large-scale applications more feasible. Digital inspection systems ensure consistent quality and compliance with global standards. These improvements contribute to extended service life and increased equipment reliability, especially in hydraulic applications where efficiency and reliability are essential.

Note: The integration of advanced chrome plating and inspection technologies supports the longevity and efficiency of industrial machinery.

Max’s Expertise in Supplying Precision Chrome-Plated Steel Bars for Industrial Applications

Quality Assurance and Testing Capabilities

Max sets a high standard for quality in the production of precision chrome-plated steel bars. The company holds ISO 9001:2015 and TS16949 certifications, which confirm strict adherence to international quality management systems. Every batch of steel undergoes rigorous inspection using advanced tools like coordinate measuring machines (CMMs) that detect dimensional deviations as small as 0.001 inches. Max applies chrome plating with automated lines to guarantee uniform coverage and consistent thickness.

Testing protocols include endurance trials, hydraulic pressure resistance tests, and salt spray corrosion tests that follow ASTM B117 and ISO 10289 standards. The company also measures friction force under controlled conditions to ensure optimal performance. Proprietary polishing techniques achieve surface roughness as low as Ra 0.20 μm, which enhances the durability of chrome plating. Each shipment includes comprehensive quality documentation, such as certified test reports, statements of quality, and certificates of conformance with traceability. Max provides detailed inspection reports like PPAP, RT, and UT, ensuring transparency and reliability.

Max’s commitment to quality ensures that precision chrome-plated steel bars meet the highest expectations for industrial use.

Technical Support and Customization

Max understands that every industrial application has unique requirements. The company controls raw materials through its subsidiary, Bar Technologies, to maintain the highest quality of steel for chrome plating. Clients can request customization in size, chemistry, hardness, and plating thickness to match their specific needs. Max offers chrome-plated bar stock in various grades, sizes, and hardness levels, with options for induction hardening and specialized surface finishes.

A dedicated technical support team assists with troubleshooting, technical inquiries, and guidance throughout the order process. Service representatives help manage orders and ensure timely delivery. Max uses specialized inventory and order tracking software to optimize delivery schedules and reduce client costs. Surface preparation services maximize corrosion resistance, and additional protection is available for extreme environments. The company also provides heat treatment options, such as quenching, tempering, or induction hardening, tailored to customer specifications.

Global Reach and Customer Satisfaction

Max supplies precision chrome-plated steel bars to clients worldwide. The company exports products to regions including Europe, Japan, Korea, Africa, Canada, the USA, and Australia. Max sources mill-certified SBQ carbon and alloy steel bars from trusted North American suppliers, ensuring compliance with material certification standards. Both in-house and independent laboratories verify corrosion resistance and product quality.

Max values customer satisfaction above all. The company emphasizes open communication and personalized solutions. Clients receive responsive after-sales service and technical support, which helps build long-term relationships. Comprehensive quality documentation and traceability provide peace of mind for customers in every market.

| Region | Quality Certifications | Testing Standards | Customer Support |

|---|---|---|---|

| North America | ISO 9001, TS16949 | ASTM B117, ISO 10289 | 24/7 Technical |

| Europe | ISO 9001 | In-house & 3rd-party | Custom Solutions |

| Asia-Pacific | ISO 9001 | Certified Labs | Fast Response |

Max’s global presence and dedication to quality make it a trusted partner for precision chrome-plated steel bars in industrial applications.

Hard chrome plated steel bars play a vital role in industrial operations. Their durability ensures reliable performance in harsh environments. Industry experts highlight their use in hydraulic systems and heavy machinery for unmatched durability and consistent performance.

- The global market is projected to reach USD 1.8 billion by 2033, showing strong demand.

- Innovations in chrome plating improve both durability and environmental impact.

- These bars support growth in automotive, aerospace, and construction sectors.

Choosing a trusted supplier like Max guarantees long-term durability, reduced maintenance, and optimal equipment performance.

FAQ

What makes hard chrome plated steel bars different from regular steel bars?

Hard chrome plated steel bars have a dense chrome layer that increases surface hardness and corrosion resistance. Regular steel bars lack this protective coating. Industry tests show chrome plated bars last up to ten times longer in harsh environments.

How does chrome plating improve equipment performance?

Chrome plating creates a smooth, low-friction surface. This finish reduces wear on moving parts and minimizes energy loss. Equipment with chrome plated bars operates more efficiently and requires less maintenance.

Which industries use hard chrome plated steel bars most often?

Hydraulic, automotive, construction, and aerospace industries rely on these bars. They use them in hydraulic cylinders, shock absorbers, heavy machinery, and aircraft components. These sectors demand high durability and reliability.

Can hard chrome plated steel bars withstand extreme conditions?

Yes. These bars resist high pressure, heavy loads, and corrosive chemicals. Salt spray tests confirm that chrome plated bars maintain integrity after 1,000+ hours in harsh environments.

Does Max offer custom sizes or finishes for chrome plated steel bars?

Max provides custom sizes, hardness levels, and chrome thickness. The company also offers induction hardening and specialized surface finishes. Technical support helps clients select the best options for their applications.