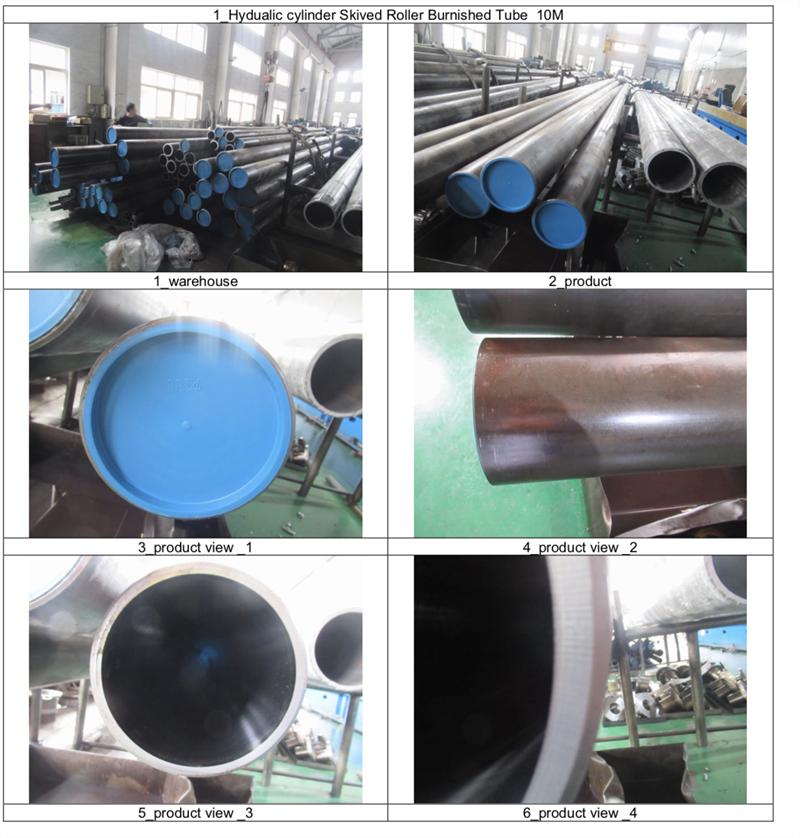

Precision Cylinder E355 ST52 H8 1020 hydraulic tube Honed Steel Pipe and Skived Roller Burnished SRB Tube

| Rod Diameter | 20mm-1500mm |

| Maximum Stroke | 630mm |

| Outer Tube Diameter | 30mm-1600mm |

| Inner Tube Diameter | 20mm-1500mm |

| Material | Carbon Steel |

| Application | Hydraulic Pipe |

| Roughness | Ra <= 0.2u |

| Diameter | 30mm-1600mm |

| Surface Treatment | Honed & SRB |

| Color | Black |

| Product name | DIN2391 ST52 H8 1020 hydraulic tube Honed Steel Pipe and Tube |

| Material | E355 ,Q345 , ST52 , SAE1026.CK45 STKM 13C |

| Length | <=13 meters |

Packing : hydraulic tube Honed Steel Pipe and Tube pack by plastic caps on both ends, then bundle with knitting strip and steel strip

MAX Auto Parts is the manufacturer and exporter of hydraulic parts . Main product range: hydraulic cylinder tube ,Honed & SRB(SKIVED AND ROLLER BURNISHED ) , chrome plated piston rod . The partner factories has got the TS16949 certificate . There is complete production facilities include : CNC machine, lathe machine, grinding machine and so on ,some of machine bought from abroad , with high precision . Max also have a series of testing equipment to control quality , such as projector, roughness tester, micro hardness tester, universal tensile machine, Metallography analyzer, thickness tester, salt spray tester . Max's engineers team with rich experiences in the line of auto parts, they will not only source products for customers, but also provide technical support , production all-time supervision and quality track service . OEM and ODM both available . Max could provide all kinds of inspection service and report include PPAP report , RT, UT, MPI, WPS & PQR and so on . Max's products have been exported to Russia , Europe, Japan ,Korea, Africa, Canada, USA, Australia and so on . Max has a good reputation and established long term relationship with customers . Max aim at got a win-win cooperate with customer , we believe that Your business is our success !

Product Application

Product Application

High power engine , hydraulic ram , and engineering forklift

Process flow :

Hot rolled seam;ess pipe – acid picking parkerising – cold drawn – heat treatment -straightening -honing or skiving and roller bunished S.R.B – inspection -Packing

Every tube before deliver have to inspection carefully ,include size check , weight check , function test , surface check and so on .