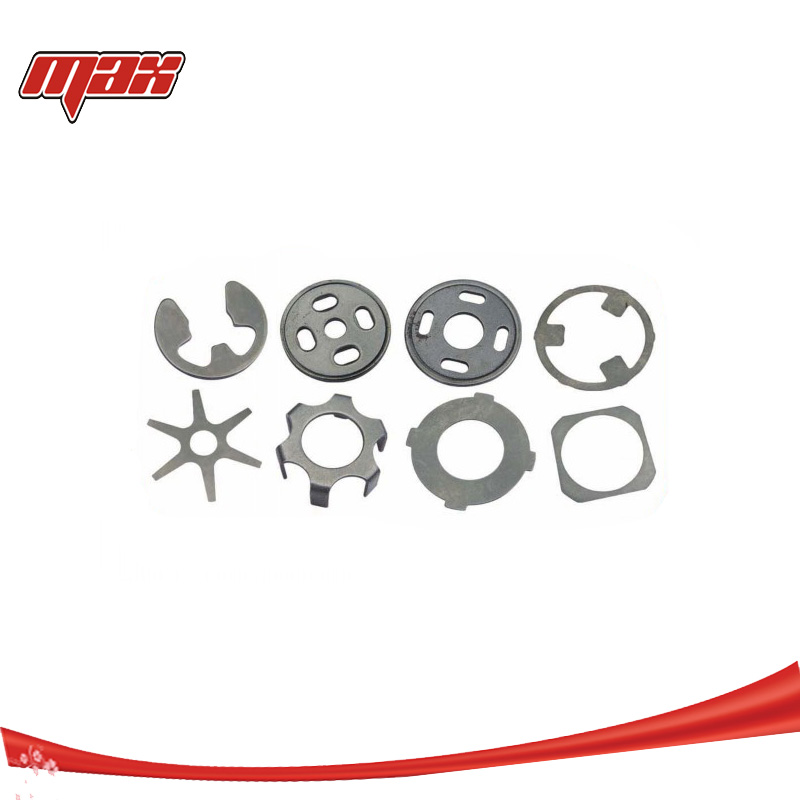

shock absorber components China made manufacturer customized Fe-C-Cu powder metal sintered parts for rod guide

Product features

The piston and the bottom valve mainly provide damping for the shock absorber ,rod guide mainly guide for the movement of piston rod.

Technological process: mixing powder – forming – sintering – cleaning -Steam treatment – Bending-Press bushing-Appearance inspection, packing

Mixing powder: Fe – C – Cu powder by high density sieve to remove impurities, automatic blending machine 360 ° rotating more than 4 hours, make the material mix evenly

Molding: precision mould with automatic CNC hydraulic press to ensure the density of all parts meet the process requirements after pressing.

Sintering: the product is controlled by the net belt type sintering furnace, which ensures the mechanical properties and hardness of the products to meet the technical requirements.

Oil immersion: place the product in a high pressure vessel so that the oil can fully penetrate into the product’s pores and avoid the rust of the later cycle.

Plastic: precision mould with full automatic CNC hydraulic press, the product density and mechanical properties are further improved after pressing, and the dimensions meet the requirements of the drawing.

Machining: finish the hole, groove and other details of the product.

Cleaning: the mesh belt adopts ultrasonic cleaning machine to remove impurities and iron filings.

Steam treatment: the product is treated by steam in the electric furnace, which improves the mechanical properties of the product, and the surface oxidation layer helps to prevent rust.

Packing: the piston is covered by a fully automatic numerical control machine covering the PTFE lubrication belt.

Press bushing: pressed into DU bushing.

Appearance inspection, packing.

specification

| item | value |

| Warranty | 1YEAR |

| Place of Origin | China |

| Zhejiang | |

| Brand Name | Max |

| Density | 6.4-6.9 g/cm3 after steam oxidation |

| Material | Fe-C-Cu Powder |

| Surface treatmen | Steam oxidation, 2 hours, Fe3O4: 0.004-0.005mm, degree of oxidation 2-4% |

| Service | OEM ODM |

| Density | 6.4-6.9 g/cm3 after steam oxidation |

| Type | DRILLING, Milling, Turning |

| Model Number: | Custom-made Service |

| Product name: | Powder Metal Sintered Part for Shock Absorber |

| Process | Sintering+ Cnc |

| Application | Shock Absorber |

| Unspecified | ISO 2768 - m / H14, h14, +- IT14/2 |

| Our Advantages | 1. More than current 3000 moulds ,save your mold cost 2. ISO/TS 16949:2009 certificate 3.Competitive price 4.Strictly quality control capacity of APQP,FEMA,MSA,PPAP,SPC |

FACTORY VIEW

Powder metallurgy is a process technology for preparing metal powder or using metal powder (or a mixture of metal powder and non-metal powder) as raw material, forming and sintering with molds to manufacture metal materials, composite materials and various types of products

Shock absorber powder metallurgy parts include piston , valve , rod guide .

FACTORY VIEW

TEST FACILITIES