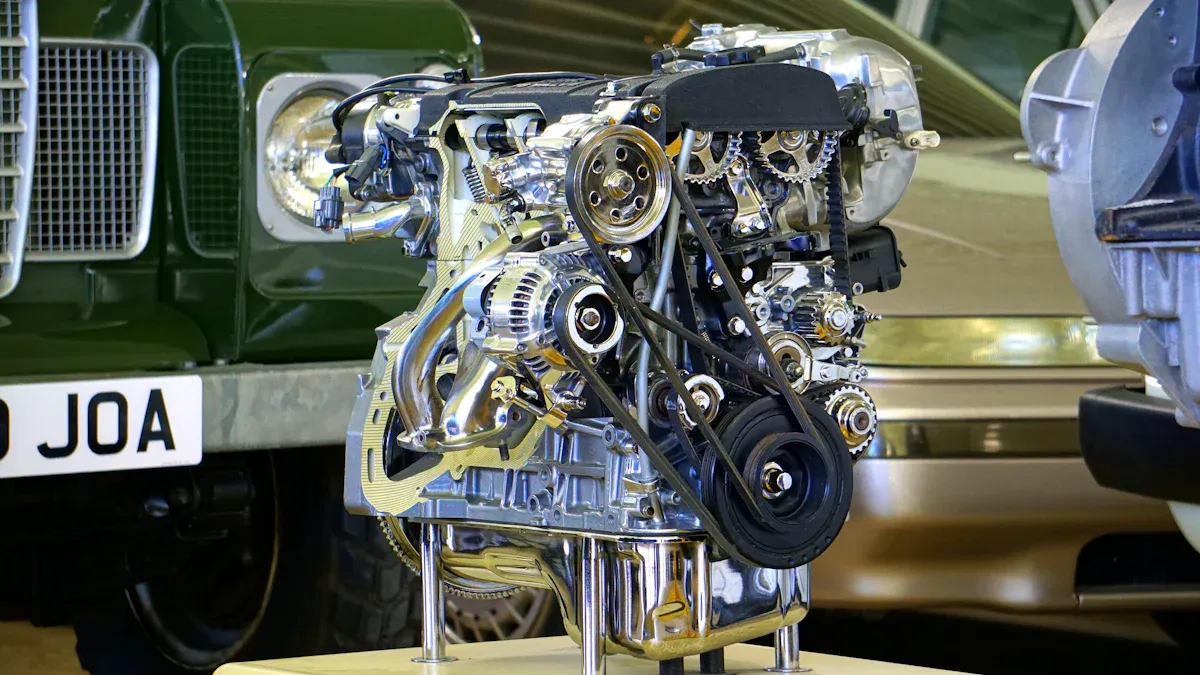

The piston with rod is a crucial component in an engine, converting combustion energy into mechanical motion that drives the crankshaft and powers your vehicle. Innovations in the design of the piston with rod have greatly improved engine performance. For instance:

- Optimized pistons with rods have demonstrated a 15–20% increase in engine power and torque efficiency during controlled tests.

- Enhanced thermal efficiency has resulted in a 10% reduction in brake-specific fuel consumption.

- Engineers have successfully reduced the weight of the piston with rod by 70 grams, contributing to improved overall performance.

These advancements underscore the significant role the piston with rod plays in boosting the efficiency and power of your engine.

Key Components of a Piston with Rod

The piston with rod assembly consists of several critical components that work together to convert combustion energy into mechanical motion. Each part plays a unique role in ensuring the engine operates efficiently and reliably. Let’s explore these components in detail.

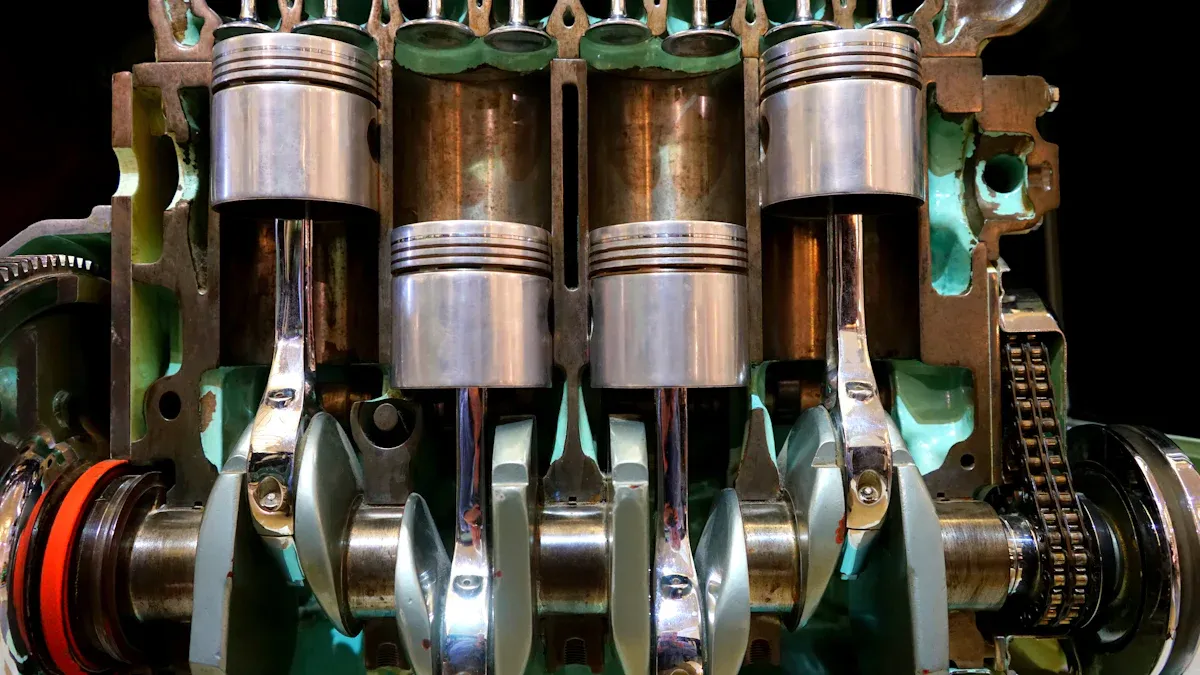

Piston

The piston is the heart of the assembly. It moves up and down within the cylinder, compressing air-fuel mixtures and transferring the force of combustion to the connecting rod. Pistons are typically made from lightweight yet durable materials like aluminum alloys to withstand high temperatures and pressures. Engineers often optimize the design of pistons to reduce weight and improve thermal efficiency. For example, reducing the weight of a piston by just 70 grams can significantly enhance engine performance.

To better understand how structural parameters affect the piston’s performance, consider the following data:

| Structural Parameter | Impact on Friction Power Loss | Impact on Slapping Energy |

|---|---|---|

| Pinhole Offset | Significant | Not specified |

| Liner Clearance | Significant | Significant |

| Piston Skirt Ovality | Significant | Not specified |

| Interaction of Liner Clearance and Skirt Ovality | Significant | Not specified |

This table highlights how factors like liner clearance and skirt ovality influence the piston’s efficiency. Proper design and maintenance of these parameters ensure smooth operation and minimize energy losses.

Piston Rings

Piston rings are small yet vital piston parts that seal the gap between the piston and the cylinder wall. They prevent combustion gases from escaping into the crankcase and ensure proper lubrication of the cylinder. A well-designed piston ring pack maintains pressure seals and reduces wear on the cylinder walls.

Studies have shown that the sealing capacity of piston rings depends on several factors:

- Ring gap variation

- Ring masses

- Elastic force variation

- Static twist variation

These factors were analyzed in a turbo diesel engine under full load conditions. The results demonstrated that proper piston ring design significantly improves inter-ring pressures and gas dynamics, ensuring optimal engine performance.

Wrist Pin

The wrist pin, also known as the gudgeon pin, connects the piston to the connecting rod. It serves as a pivot point, allowing the piston to move freely while transferring combustion forces to the rod. The alignment and load-bearing capacity of the wrist pin are critical for the assembly’s durability.

If the connecting rod bends or twists, it can misalign the wrist pin bore, leading to uneven forces and premature wear. Engineers typically limit the maximum allowable bend to 0.001 inches per inch of rod length. Excessive bending or twisting can cause tapered oil clearance, rod bearing failure, and wear on the piston’s pin bore.

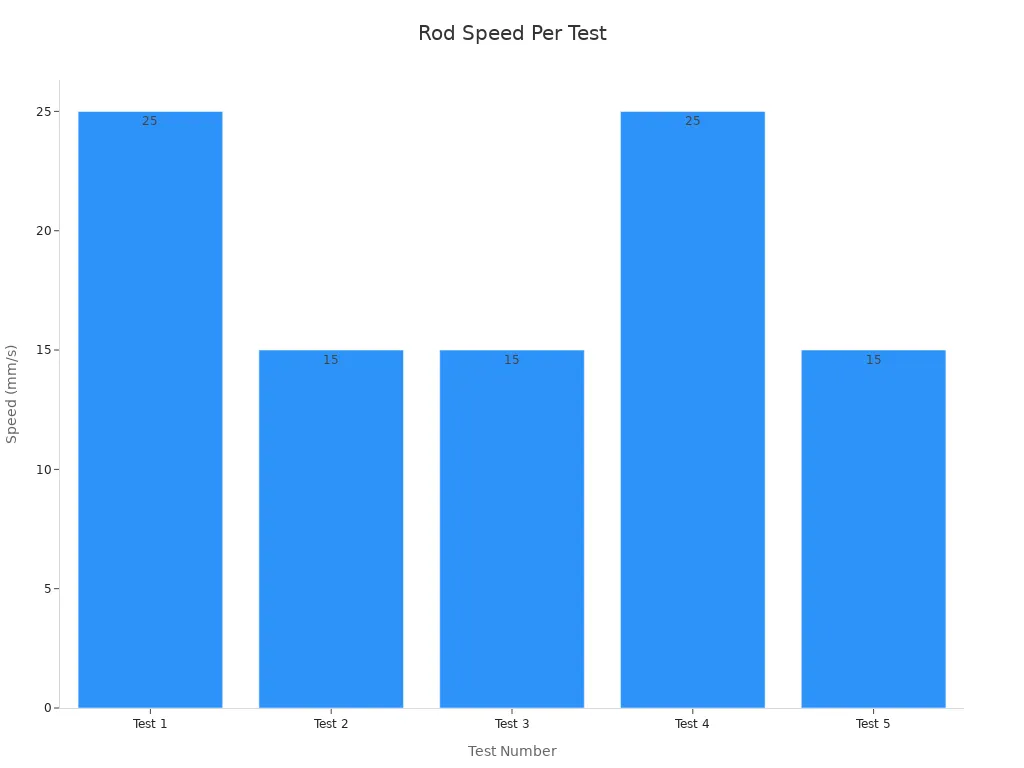

To ensure reliability, engineers conduct rigorous tests on piston rod assemblies. The following chart illustrates the results of tests conducted under various conditions:

These tests demonstrate the importance of maintaining proper alignment and load distribution in wrist pins to prevent failures and extend the lifespan of the piston with rod assembly.

Connecting Rod

The connecting rod plays a vital role in the piston assembly. It links the piston to the crankshaft, transferring the linear motion of the piston into rotational motion that powers the engine. This component must endure extreme forces, including the explosive pressure from combustion and the rapid changes in direction during operation. Its design and material significantly impact engine performance and durability.

Design and Material Considerations

Engineers carefully select materials for connecting rods to balance strength, weight, and stiffness. A lighter connecting rod reduces the engine’s reciprocating mass, improving efficiency and reducing wear on other piston parts. However, it must also maintain sufficient strength to handle the immense forces generated during combustion.

Here’s a comparison of two commonly used materials for connecting rods:

| Material | Factor of Safety (FOS) | Weight | Stiffness |

|---|---|---|---|

| Titanium Alloy | 17.69 | 1.8524 | 383.51 |

| Beryllium Alloy | 4.747 | 3.36 | 772.609 |

Titanium alloy offers a higher factor of safety and lower weight, making it ideal for high-performance engines. Beryllium alloy, on the other hand, provides greater stiffness but is heavier, which may not suit all applications. You can see how these trade-offs influence the choice of material based on the engine’s specific requirements.

Functionality and Alignment

The connecting rod must remain perfectly aligned to ensure smooth operation. Misalignment can lead to uneven wear on the piston and crankshaft, reducing the lifespan of these critical piston parts. Engineers often test connecting rods under various conditions to ensure they meet strict performance standards. Proper alignment also minimizes energy losses, ensuring the engine operates efficiently.

Enhancing Performance

Modern advancements have led to the development of lightweight connecting rods with improved durability. These innovations reduce stress on the piston and crankshaft, allowing the engine to achieve higher RPMs without compromising reliability. For example, high-performance connecting rods often feature precision machining and advanced coatings to reduce friction and wear.

By understanding the role of the connecting rod and its interaction with the piston, you can appreciate how this component contributes to the overall efficiency and power of your engine. Regular maintenance and proper material selection ensure that your engine performs at its best.

How a Piston with Rod Functions in an Engine

Combustion and Energy Conversion

The piston with rod plays a central role in converting the energy from combustion into mechanical motion. Inside the engine, the combustion chamber houses the piston. When the air-fuel mixture ignites, it creates a rapid expansion of gases. This explosion generates immense pressure, forcing the piston downward within the cylinder. This downward motion is the first step in transforming chemical energy into usable mechanical energy.

The effectiveness of this energy conversion depends on precise engineering. For example, a numerical model focusing on piston ring design has validated this process. Measurements like ring tension force and light-tightness confirm the model’s accuracy. These factors ensure the piston maintains proper contact with the cylinder wall, reducing friction loss and managing thermal loads. By optimizing these interactions, the engine achieves better performance and efficiency.

Linear to Rotational Motion

The piston’s movement inside the cylinder is linear, but engines require rotational motion to drive components like the wheels or propellers. This transformation occurs through the connecting rod, which links the piston to the crankshaft. As the piston moves downward during combustion, the connecting rod pushes against the crankshaft, causing it to rotate. When the piston moves upward during the exhaust stroke, the connecting rod pulls the crankshaft in the opposite direction, continuing the rotation.

This back-and-forth motion creates a smooth rotational force. The design of the connecting rod ensures that the piston’s linear motion translates efficiently into rotation. Engineers carefully balance the weight and strength of the connecting rod to minimize energy loss and wear. This balance allows the engine to operate smoothly, even at high speeds.

Role of the Crankshaft

The crankshaft is the final link in converting the piston’s motion into rotational energy. It connects to the connecting rod through crankpins and journals, which allow it to rotate as the piston moves. When the piston moves downward due to combustion, the crankshaft absorbs this force and converts it into rotational energy. This rotational energy powers the engine’s output, driving the vehicle or machinery.

The crankshaft must endure significant forces while maintaining stability. Its design minimizes vibrations and ensures smooth operation. For instance, the crankshaft’s structure directly influences the engine’s efficiency and power delivery. By reducing vibrations, it prevents unnecessary wear on the piston with rod assembly and other engine components. This careful engineering ensures the engine operates reliably and delivers consistent performance.

Common Issues with Pistons and Rods

Piston Slap

Piston slap occurs when the piston moves sideways within the cylinder instead of maintaining a smooth up-and-down motion. This issue often arises due to excessive clearance between the piston and the cylinder wall. You may notice a knocking sound during engine operation, especially when the engine is cold. Over time, piston slap can lead to increased wear on piston parts and reduced engine efficiency.

To prevent piston slap, ensure proper maintenance of the cylinder liner clearance. Regular inspections help identify early signs of wear or misalignment. If left unchecked, piston slap can damage the cylinder wall and compromise the piston’s ability to transfer combustion energy effectively.

Worn Piston Rings

Worn piston rings are another common issue that affects engine performance. These rings seal the gap between the piston and the cylinder wall, preventing combustion gases from escaping and ensuring proper lubrication. When piston rings wear out, you may experience reduced compression, increased oil consumption, and visible smoke from the exhaust.

Several factors contribute to piston ring wear, including improper installation, poor lubrication, and high operating temperatures. Regularly checking the condition of the piston rings can help you avoid these problems. Replacing worn rings promptly restores the seal and improves the engine’s efficiency.

Connecting Rod Failures

Connecting rod failures can severely impact engine functionality. These rods endure immense forces during combustion and must remain aligned to transfer motion effectively. Misalignment or excessive wear can lead to uneven stress distribution, causing the rod to bend or break.

A study analyzing diesel engine connecting rod big-end bearings highlights how lubrication dynamics play a critical role in preventing wear failures. Increased wear clearance leads to higher rough contact forces and deteriorating lubrication states, which accelerate rod damage. Regular lubrication checks and proper alignment minimize these risks.

When connecting rods fail, they can damage other piston parts, including the crankshaft and wrist pin. To avoid costly repairs, inspect the connecting rods periodically and address any signs of wear or misalignment.

Impact on Engine Efficiency

The piston plays a crucial role in determining your engine’s efficiency. Its design, material, and functionality directly influence how effectively the engine converts fuel into mechanical energy. When the piston operates smoothly, it minimizes energy losses and ensures optimal performance.

One key factor affecting efficiency is the piston’s ability to maintain a proper seal within the cylinder. This seal prevents combustion gases from escaping, allowing the engine to generate maximum power. Piston rings, which are essential piston parts, help achieve this seal. If these rings wear out or fail, the engine loses compression, leading to reduced power output and increased fuel consumption.

The weight of the piston also impacts efficiency. A lighter piston reduces the engine’s reciprocating mass, which lowers the energy required to move it. This improvement translates into better fuel economy and smoother operation. Engineers often use advanced materials like aluminum alloys to create lightweight yet durable pistons that withstand high temperatures and pressures.

Thermal management is another critical aspect. Pistons must dissipate heat effectively to avoid overheating, which can damage the engine. Modern pistons feature optimized designs and coatings that enhance heat resistance and reduce friction. These advancements improve the engine’s thermal efficiency, allowing it to extract more energy from each combustion cycle.

Proper maintenance of piston parts is essential for sustaining engine efficiency. Regular inspections help identify issues like worn rings or misaligned pistons before they escalate. By addressing these problems early, you can ensure your engine operates at peak efficiency, saving fuel and extending its lifespan.

Tip: Always use high-quality replacement pistons and parts to maintain your engine’s performance and efficiency.

Enhancements for Pistons and Rods

High-Performance Pistons

High-performance pistons are designed to improve engine efficiency and durability. These pistons often feature advanced designs that optimize combustion and reduce emissions. For example, the Volvo Group developed a wave piston design that enhances fuel efficiency and lowers emissions. Computational fluid dynamics (CFD) testing revealed that this design improves combustion, reduces soot particle emissions by 50%, and decreases fuel consumption by 2%.

You can benefit from these innovations by upgrading to high-performance pistons, especially if you seek better fuel economy or reduced environmental impact. These pistons also withstand higher pressures and temperatures, making them ideal for high-performance or turbocharged engines.

Friction-Reducing Coatings

Friction-reducing coatings play a vital role in enhancing the performance of piston parts. These coatings minimize resistance between the piston and cylinder wall, reducing wear and improving efficiency. Studies have shown that different coatings offer varying levels of friction reduction:

| Coating Type | Impact on Friction Reduction | Study Reference |

|---|---|---|

| TiN | Significant reduction in resistance torque | Wróblewski & Rogólski |

| TiAlN | Notable improvement in performance | Wróblewski & Rogólski |

| CrN | Enhanced durability and lower friction | Wróblewski & Rogólski |

| DLC1 | Optimal friction reduction observed | Wróblewski & Rogólski |

By applying these coatings, you can extend the lifespan of your pistons and improve overall engine performance. Coatings like DLC1 are particularly effective, offering superior friction reduction and durability.

Lightweight Connecting Rods

Lightweight connecting rods significantly enhance engine performance by reducing the reciprocating mass. A lighter rod requires less energy to move, improving fuel efficiency and allowing the engine to achieve higher RPMs. Engineers achieve this by optimizing the rod’s structural design and using materials like forged steel or aluminum.

Studies highlight the importance of balancing strength and weight. Stress analysis under various conditions shows that lightweight rods maintain durability while reducing production costs and improving efficiency. For example, aluminum rods offer excellent strength-to-weight ratios, making them a popular choice for high-performance engines.

Upgrading to lightweight connecting rods can transform your engine’s performance. You’ll notice smoother operation, better fuel economy, and reduced wear on other piston parts.

Durability Upgrades for Racing Engines

Racing engines demand exceptional durability to handle extreme conditions. Upgrading the piston with rod assembly ensures your engine performs reliably under high stress. These enhancements focus on reducing wear, improving heat management, and extending the lifespan of critical components.

One effective upgrade involves advanced piston ring technology. Thinner rings, such as .7mm, .7mm, 2.0mm configurations, significantly improve thermal management. Tests at Shaver Specialties Racing Engines revealed that these rings reduced water temperatures by 15 degrees and oil temperatures by nearly 20 degrees compared to standard rings. Lower temperatures prevent overheating and double the service life of engine oil. This improvement enhances the durability of your racing engine, allowing it to perform consistently during intense competition.

Material selection also plays a key role in durability upgrades. High-performance pistons made from forged aluminum alloys resist deformation and withstand extreme pressures. These pistons dissipate heat effectively, reducing the risk of thermal damage. Lightweight connecting rods complement these pistons by minimizing stress on the crankshaft and improving energy transfer. Together, these components create a robust assembly that endures the demands of racing.

Coatings further enhance durability. Friction-reducing coatings, such as diamond-like carbon (DLC), protect the piston and cylinder walls from wear. These coatings reduce friction, allowing smoother operation and extending the lifespan of the piston with rod assembly. By incorporating these upgrades, you can ensure your racing engine remains reliable and efficient, even under the harshest conditions.

Regular maintenance is essential to maximize the benefits of durability upgrades. Inspect the piston and connecting rod for signs of wear or misalignment. Replace worn components promptly to maintain optimal performance. With these upgrades and proper care, your racing engine will deliver peak performance and unmatched reliability.

The piston with rod is essential for converting combustion energy into mechanical motion, driving the engine’s performance. By understanding its components and functions, you can maintain your engine effectively and identify issues early. For example, hollow connecting rods reduce weight while maintaining durability, leading to increased fuel efficiency and supporting global initiatives for lighter vehicles.

Exploring enhancements like electric actuators offers significant benefits. These actuators provide high efficiency, lower utility costs, and virtually maintenance-free operation compared to pneumatic cylinders.

| Feature | Electric Actuators | Pneumatic Cylinders |

|---|---|---|

| Efficiency | High efficiency, lower utility costs | Lower efficiency, higher utility costs |

| Maintenance | Virtually maintenance-free | Requires regular maintenance |

| Total Cost of Ownership | Lower over the system’s life | Higher over the system’s life |

| Motion Flexibility | Complete motion flexibility | Limited motion flexibility |

| Control | Closed loop control for data collection | Open loop control |

By leveraging these advancements, you can enhance your engine’s efficiency and extend its lifespan, ensuring optimal performance for years to come.

FAQ

What is the purpose of a piston with rod in an engine?

The piston with rod converts combustion energy into mechanical motion. The piston moves up and down in the cylinder, while the connecting rod transfers this motion to the crankshaft, creating rotational energy that powers the engine.

How do piston rings improve engine performance?

Piston rings seal the gap between the piston and cylinder wall. They prevent gas leaks, maintain compression, and ensure proper lubrication. This improves fuel efficiency, reduces emissions, and minimizes wear on engine components.

What materials are commonly used for pistons and rods?

Pistons are often made from aluminum alloys due to their lightweight and heat resistance. Connecting rods typically use forged steel or titanium for strength and durability, especially in high-performance engines.

How can you identify piston slap in your engine?

You may hear a knocking sound, especially when the engine is cold. This happens when the piston moves sideways in the cylinder due to excessive clearance. Regular inspections can help detect and prevent this issue.

Are lightweight connecting rods worth upgrading?

Yes, lightweight rods reduce the engine’s reciprocating mass. This improves fuel efficiency, allows higher RPMs, and reduces wear on other components. They are especially beneficial for high-performance or racing engines.

Tip: Always consult a professional before upgrading engine components to ensure compatibility and optimal performance.