Shock abosorber powder metallurgy accessories

Through sintered parts, it can meet the structural requirements of various shock absorbers. At the same time, reasonable metal powder mixing is used to make its wear resistance and corrosion resistance stronger, and the internal gap can better play the effect of shock absorption and sound insulation.

2.Process characteristics

1. the density of the product is controllable, such as porous materials, good density materials;

2. fine grain, uniform microstructure, no component segregation;

3. near forming, raw material utilization rate > 95%;

4.less no cutting, cutting processing only 40~50%;

5. the composition of materials is controllable, which is conducive to the preparation of composite materials;

6. preparation of refractory metal, ceramic materials and nuclear materials.

3.Product usage

Shock absorbers are mainly used to suppress the shock and impact brought by spring shock absorption and rebound, so as to improve the ride of cars, agricultural machinery and so on.

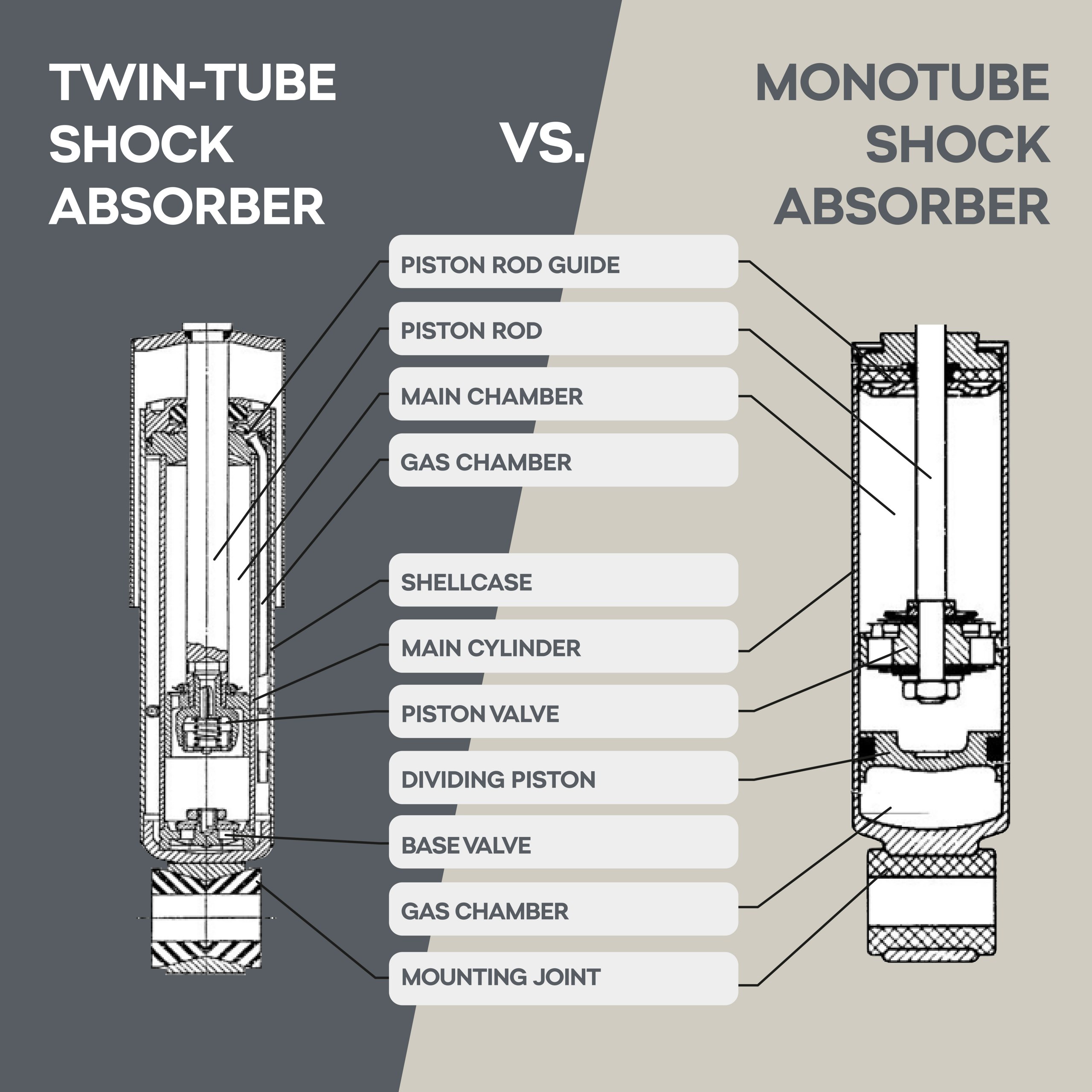

Shock absorber powder metallurgy accessories include: 1. Piston rod; 2. Working cylinder; 3. The piston; 4. Stretch valve; 5. Oil cylinder; 6. Compression valve; 7. Compensation valve; 8 flow valve; 9. Guide seat; 10. Dust cover; 11. Oil seal.

Max auto parts specializing in the production of various shock absorber powder metallurgy accessories.We easy to do business, you can start working with us with sample order.We can also develop new moulds and customize according to your drawings.

Post time: Jun-24-2022