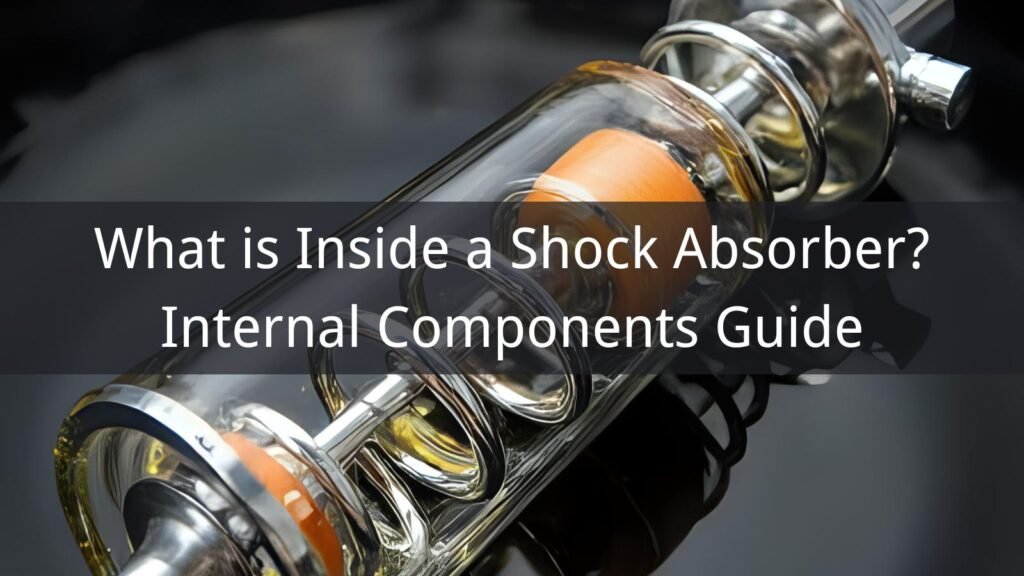

Understanding what’s inside a shock absorber reveals the sophisticated engineering behind these critical automotive components. From chrome-plated piston rods to precision valve systems, each internal element plays a vital role in controlling vehicle dynamics, comfort, and safety through advanced hydraulic damping technology.

Table of Contents

Shock Absorber Anatomy Overview

Inside every shock absorber lies a complex assembly of precisely engineered components working together to control suspension movement. The internal structure of a shock absorber, also known as a damper, consists of multiple systems that convert kinetic energy into thermal energy through hydraulic resistance.

The primary internal components include the piston rod assembly, hydraulic cylinder, valve systems, sealing mechanisms, and specialized fluids. Each element must withstand extreme pressures, temperature variations, and constant reciprocating motion while maintaining consistent performance over hundreds of thousands of cycles.

Modern shock absorber systems incorporate advanced materials and manufacturing techniques to achieve superior durability and performance characteristics compared to earlier mechanical designs.

Piston Rod Assembly Components

The piston rod assembly forms the heart of any shock absorber, transmitting forces between the wheel assembly and vehicle body while providing the primary damping mechanism. This critical component consists of several interconnected elements that must work in perfect harmony.

Piston Rod Construction

The piston rod itself is typically manufactured from high-strength steel and features a precision-machined surface finish. Hard chrome-plated piston rods provide exceptional corrosion resistance and reduced friction, significantly extending service life even in harsh operating conditions.

| Component | Material | Primary Function | Critical Properties |

|---|---|---|---|

| Piston Rod | Chrome-plated steel | Force transmission | Corrosion resistance, surface hardness |

| Piston Head | Powder metallurgy | Hydraulic control | Porosity, dimensional accuracy |

| Piston Ring | PTFE/Bronze composite | Sealing and guidance | Wear resistance, low friction |

| Valve Discs | Spring steel | Flow regulation | Fatigue resistance, precise deflection |

Piston Head Design

The piston head contains carefully designed passages and valve arrangements that control hydraulic fluid flow during compression and rebound cycles. Our sintered components utilize advanced powder metallurgy technology to achieve precise porosity and dimensional control.

Piston heads typically feature multiple flow circuits with different opening pressures and flow characteristics. This sophisticated design allows for velocity-sensitive damping that automatically adjusts to varying road conditions and driving demands.

Rod Attachment Methods

The connection between the piston and rod requires exceptional strength and reliability. Common attachment methods include threaded connections with thread-locking compounds, press-fit assemblies, and welded joints. The piston rod connection must withstand both tensile and compressive loads throughout the damper’s service life.

Hydraulic System Elements

The hydraulic system within a shock absorber creates the damping force through controlled fluid resistance. This system consists of specialized fluids, pressure chambers, and flow control mechanisms that work together to provide consistent performance across a wide range of operating conditions.

Hydraulic Fluid Properties

Shock absorber fluid, typically a specially formulated hydraulic oil, must maintain consistent viscosity across temperature ranges from -40°F to 300°F. The fluid serves multiple functions:

- Energy dissipation through viscous shearing

- Heat transfer and cooling

- Lubrication of internal components

- Corrosion protection for metal surfaces

Pressure Chambers

Twin-tube shock absorbers feature separate working and reservoir chambers, while monotube designs utilize a single chamber with a floating piston separating hydraulic fluid from pressurized nitrogen gas. The gas charge prevents cavitation and maintains consistent damping performance.

Flow Control Systems

Sophisticated flow control mechanisms regulate fluid movement during compression and extension cycles. These systems incorporate multiple valve stages with different opening pressures to provide progressive damping characteristics.

Valve Mechanisms and Control Systems

The valve systems inside shock absorbers represent some of the most sophisticated hydraulic engineering in automotive applications. These mechanisms precisely control fluid flow to provide optimal damping characteristics across varying vehicle speeds and road conditions.

Shim Stack Valves

Shim stack valves consist of thin steel discs stacked in specific sequences to create precise opening pressures and flow characteristics. Each shim has a specific thickness and diameter, with the stack configuration determining the valve’s response curve. Our shock shims are manufactured to exacting tolerances to ensure consistent performance.

Base Valve Assembly

Located at the bottom of twin-tube shock absorbers, the base valve controls fluid transfer between the working cylinder and outer reservoir. This component features separate circuits for compression and rebound flow, each with calibrated opening pressures.

| Valve Type | Location | Function | Adjustment Method |

|---|---|---|---|

| Compression Valve | Piston face | Controls compression damping | Shim stack configuration |

| Rebound Valve | Piston face | Controls extension damping | Shim stack configuration |

| Base Valve | Cylinder bottom | Reservoir flow control | Fixed calibration |

| Blow-off Valve | Various locations | Pressure relief | Spring preload |

Adjustable Valve Systems

High-performance shock absorbers often incorporate adjustable valve systems that allow fine-tuning of damping characteristics. These may include external adjusters that modify bypass flow or internal mechanisms that alter shim stack preload.

Sealing Systems and Gaskets

The sealing system prevents hydraulic fluid leakage while accommodating constant rod movement and pressure variations. Modern shock absorbers employ multiple sealing stages with different functions and operating characteristics.

Primary Rod Seal

The primary rod seal provides the main barrier against fluid leakage and typically consists of a lip-type seal made from specialized elastomeric materials. This seal must accommodate rod movement while maintaining pressure integrity across temperature extremes.

Wiper Seal

Located at the cylinder head, the wiper seal removes contaminants from the rod surface during operation. This component prevents dirt, moisture, and debris from entering the hydraulic system, which could cause internal damage or performance degradation.

Guide Bearing

The guide bearing, often integrated with the sealing system, maintains precise rod alignment within the cylinder. This component reduces side loads and friction while providing smooth rod movement throughout the stroke range.

Cylinder Construction and Materials

The shock absorber cylinder provides the structural foundation for all internal components while containing hydraulic fluid under pressure. Cylinder construction varies between twin-tube and monotube designs, each with specific advantages and manufacturing requirements.

Cylinder Materials

Most shock absorber cylinders are manufactured from seamless steel tubing with specialized internal surface treatments. Hard chrome plating of internal surfaces provides exceptional wear resistance and corrosion protection.

Twin-Tube Construction

Twin-tube shock absorbers feature an inner working cylinder surrounded by an outer reservoir tube. The space between cylinders serves as a fluid reservoir and thermal buffer, allowing for larger fluid capacity and improved heat dissipation.

Monotube Design

Monotube shock absorbers utilize a single large-diameter cylinder with a floating piston separating hydraulic fluid from pressurized gas. This design offers superior heat dissipation and mounting flexibility but requires more precise manufacturing tolerances.

Common Internal Component Failures

Understanding how internal shock absorber components fail helps in diagnosis and prevention of premature failure. Most internal failures result from contamination, wear, or manufacturing defects that compromise hydraulic integrity.

Seal Deterioration

Seal failure represents the most common internal problem, typically manifesting as external fluid leakage. Factors contributing to seal deterioration include:

- Age-related material hardening and cracking

- Chemical compatibility issues with hydraulic fluid

- Rod surface damage causing seal wear

- Excessive operating temperatures

Valve System Problems

Valve system failures can cause erratic damping performance or complete loss of control. Common issues include shim stack fatigue, contamination blocking flow passages, and valve seat wear from debris or cavitation damage.

Rod and Cylinder Wear

Internal wear typically occurs when contamination enters the hydraulic system or when inadequate lubrication causes metal-to-metal contact. Proper cleaning techniques help prevent contamination that leads to internal wear.

Manufacturing Quality and Materials

The quality of internal shock absorber components directly impacts performance, reliability, and service life. Advanced manufacturing processes and material selection ensure consistent quality and optimal performance characteristics.

Material Selection

Each internal component requires specific material properties to withstand its operating environment. For example, hardened chrome rods provide exceptional durability in high-stress applications, while specialized elastomers ensure long-term sealing performance.

Quality Control Processes

At Max Auto, we employ comprehensive quality control measures throughout the manufacturing process. Our TS16949 certification demonstrates compliance with automotive quality standards, while our advanced testing equipment ensures every component meets stringent specifications.

Our quality control equipment includes:

- Projectors for dimensional verification

- Roughness testers for surface finish analysis

- Micro hardness testers for material properties

- Universal tensile machines for strength testing

- Metallography analyzers for material structure

- Salt spray testers for corrosion resistance

Manufacturing Precision

The precision required for internal shock absorber components demands advanced manufacturing capabilities. Our piston rod manufacturing process incorporates multiple quality checkpoints to ensure dimensional accuracy and surface finish requirements.

Max Auto: Your Partner for Quality Components

Understanding what’s inside a shock absorber highlights the complexity and precision required for reliable performance. At Max Auto, our comprehensive product range includes all critical internal components:

- Shock absorber piston rods with premium chrome plating

- Precision-manufactured sintered components

- High-quality valve shims and control elements

- Shock absorber springs for complete assemblies

Engineering Support and Technical Expertise

Our experienced engineering team provides comprehensive technical support for shock absorber component selection and application. We offer both OEM and ODM services, complete with PPAP documentation and ongoing quality tracking.

Global Quality Standards

Max Auto products meet international quality standards and are trusted by customers across Europe, Japan, Korea, Africa, Canada, USA, and Australia. Our commitment to quality ensures reliable performance in demanding automotive applications.

Contact Information

For technical consultation or component specifications, contact our expert team:

- Website: nbmaxauto.com

- Email: sales@maxautoparts.cn

- Phone: +86 15267273091

- Address: Building No.2, Jinshan Road No.788, Jiangbei District, Ningbo City, Zhejiang, China

- Hours: Monday-Friday: 9am to 6pm | Saturday, Sunday: Closed

Whether you need replacement internal components, complete assemblies, or technical consultation on shock absorber design, Max Auto provides the expertise and quality products to meet your specific requirements. Our dedication to manufacturing excellence ensures optimal performance and reliability in every component we produce.