With the development of science and technology, automobiles have higher requirements for shock absorbers. At present, adjustable resistance shock absorbers are becoming mainstream shock absorbers. With continuous research and development, the intelligence will become higher and higher, and the Towards the direction of adaptive adjustable shock absorbers, no matter how the driver’s driving skills are, the suspension system will automatically adjust the state to adapt to it, so that the driver feels smooth and comfortable.

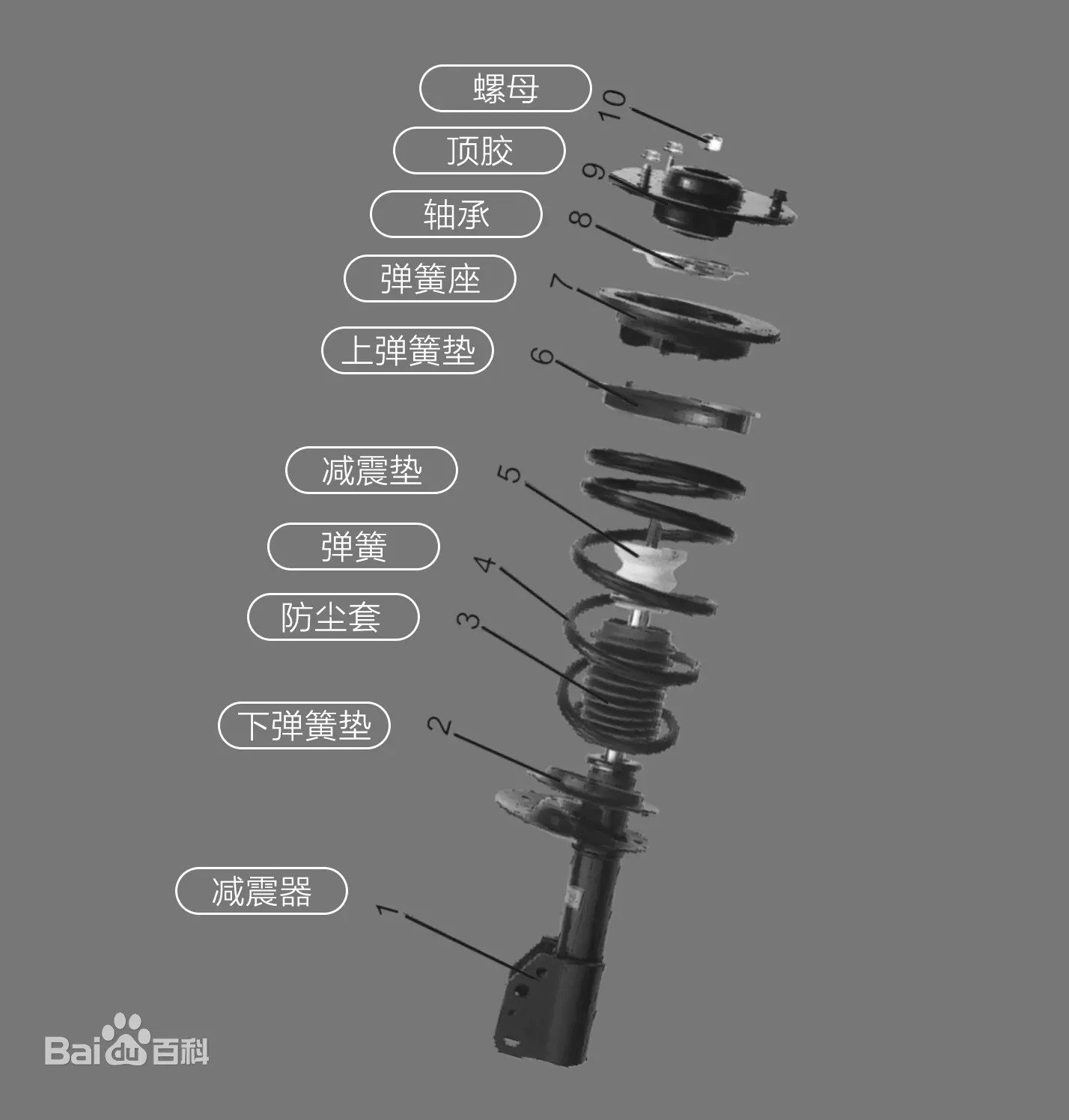

In order to quickly attenuate the vibration of the frame and body and improve the ride comfort and comfort of the car, the suspension system of the car is generally equipped with a shock absorber, and the two-way acting barrel shock absorber is widely used in the car. The shock absorber is a vulnerable part during the use of the car. The performance of the shock absorber will directly affect the driving stability of the car and the life of other parts. Therefore, the shock absorber should always be in good working condition.

According to the “2022-2027 In-Depth Research and Future Development Trend Forecast Report on the Automotive Shock Absorber Industry” released by Zhongyan Puhua Industry Research Institute:

With the rapid development of the domestic automobile industry, the shock absorber industry is also developing rapidly. At present, there are more than 100 large-scale shock absorber manufacturers. However, domestic shock absorber technology is still relatively backward, and the shock absorber technology of domestic high-end models still needs to be imported. These indicate that domestic shock absorber manufacturers still need to work hard to keep up with the pace of international advanced technology to develop independent products.

At present, the resistance adjustable shock absorber is becoming the mainstream shock absorber. With continuous research and development, the intelligence will become higher and higher, and it will develop in the direction of adaptive adjustable shock absorber, regardless of the driver’s driving skills. , the suspension system will automatically adjust the state to adapt to it, so that the driver feels smooth and comfortable. It mainly uses sensors to detect the driving state, and then calculates the driving damping force through the computer, and then automatically adjusts the damping force adjustment mechanism, and changes the damping force of the shock absorber by changing the size of the orifice.

Market supply and demand pattern analysis of automobile shock absorber industry

From the perspective of market demand in my country’s automotive shock absorber industry segment, the industry is mainly concentrated in cars and SUVs, of which cars account for 54.52%. The main reason is that these two models have the largest number of models in the market, so the demand is relatively strong. In addition to nearly 10% of multi-purpose vehicles (MPV), other demand fields are below 2%. On the whole, the concentration of market segments is relatively high.

The production of domestic shock absorbers is far from meeting the market demand, especially the supply of shock absorbers for mid-to-high-end automobiles is in short supply, and the gap still depends on imports. At the same time, there are too many domestic shock absorber manufacturers, and the market competition is at a homogeneous and low-price level. Under the condition that major foreign shock absorber companies continue to enter the domestic market, domestic companies will face the “danger” and “opportunity” of survival. “.

In the automotive shock absorber market, the gap between my country’s independent brands and foreign manufacturers in the field of high-end products is still obvious. The shock absorber industry in developed regions such as Europe, America, Japan, and South Korea started early and developed rapidly, with strong technology and research and development capabilities, especially in terms of eliminating vibration source impact and product sealing technology. They are ahead of domestic independent brand manufacturers. It is expected that as my country’s independent brand shock absorber manufacturers continue to increase research and development efforts and gradually improve their high-tech level, the competitiveness of my country’s domestically produced mid-to-high-end shock absorber products is expected to further increase.

The automobile shock absorber industry has a high degree of marketization, sufficient competition and low concentration. In developed regions of the automobile industry, internationally renowned shock absorber manufacturers maintain scale advantages and market positions through self-production and global procurement. In China, automobile shock absorber manufacturers are basically concentrated in the Northeast, Beijing-Tianjin, Central China, Southwest, Yangtze River Delta, Pearl River Delta and other auto parts industry concentration areas, among which the Yangtze River Delta region accounts for a particularly prominent proportion.

Judging from the regional distribution of sales revenue of my country’s automobile shock absorber industry, it is mainly concentrated in East China, accounting for 46.58%; Northeast China, North China, Central China and South China have also formed a certain scale, accounting for more than 10%; sales The lowest income is in the Northwest Territories, at just 0.9%.

In actual use, the shock absorber will have a sound failure, which is mainly due to the collision between the shock absorber and the leaf spring, frame or axle, damage or fall off of the rubber pad, deformation of the shock absorber dust-proof cylinder, and insufficient oil, etc. If the cause is caused, the cause should be found out and repaired. After the shock absorber is inspected and repaired, the working performance test should be carried out on a special test bench. When the resistance frequency is 100±1mm, the resistance of its extension stroke and compression stroke should meet the regulations. For example, Jiefang CA1091 has a maximum resistance of 2156~2646N in the extension stroke, and a maximum resistance of 392~588N in the compression stroke; Dongfeng Motor has a maximum resistance of 2450~3038N in the extension stroke, and 490~686N in the compression stroke. If there are no test conditions, we can also use an empirical method, that is, use an iron rod to penetrate into the lower end of the shock absorber, step on both ends of the shock absorber, hold the upper ring with both hands and pull it back and forth 2 to 4 times. There is a lot of resistance when you pull it up, but you don’t feel strenuous when you press it down, and the stretching resistance has recovered compared to before the repair, and there is no sense of space, which means that the shock absorber is basically normal.