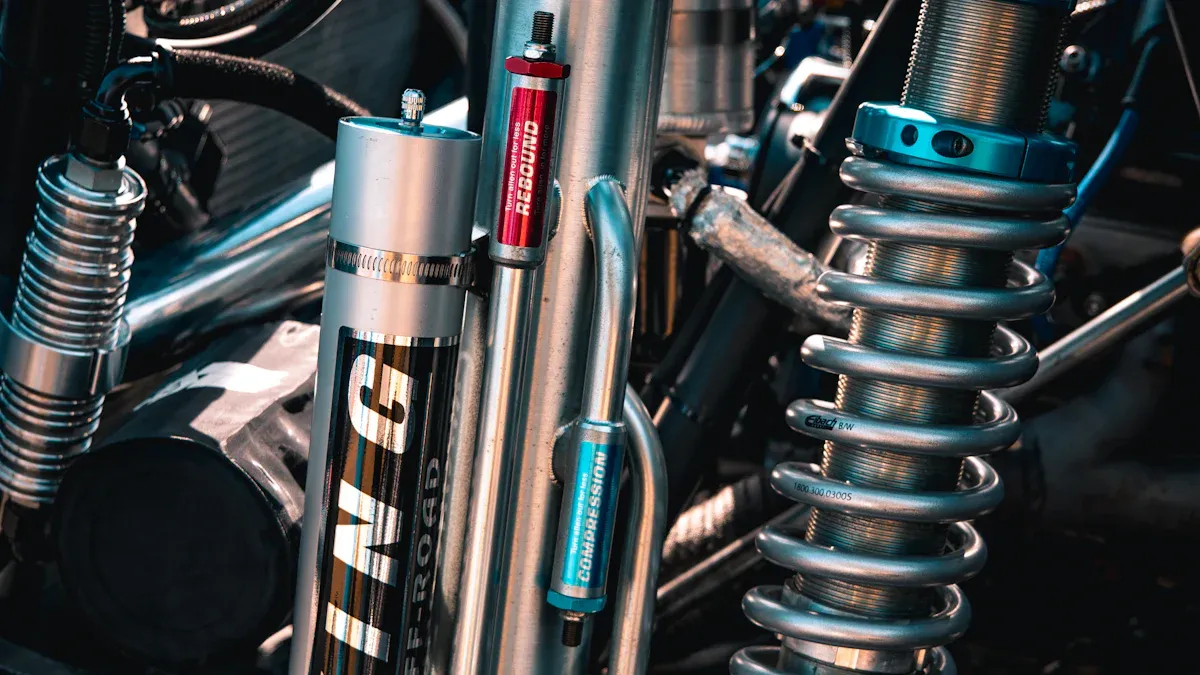

Shock Absorber sintered part

Powder metallurgy makes solid parts using powdered materials. Fine metal powders are shaped into forms using molds. These shapes, called “green parts,” are heated carefully. This heating process, called sintering, bonds the particles together. The particles stick without fully melting. The result is a strong and precise part.

This method is used in industries like cars, planes, and electronics. It creates complex shapes with little waste, saving money and materials.

Benefits of Powder Sintered Parts for Shock Absorbers

01

High strength, wear resistance

Powder sintered parts are strong and resist wearing out. During sintering, they become denser and tougher. Higher density makes them handle stress and impacts better. Properties like yield strength and impact strength improve with density. This makes them perfect for shock absorbers, which need to last long.

02

high precision

Sintering technology allows for more creative designs, making complex shapes that are hard or impossible to make using regular manufacturing methods. It allows for precise control over the size and shape of parts, reducing the risk of incompatibility or failure.

03

Lightweight Design

Sintered parts are lightweight. Compared with traditional processing methods, less labor is required. The process uses only the necessary materials, thereby reducing waste. Once the metal powder is ready, the pressing and sintering stages can be automated, which not only shortens production time but also reduces costs.

Role of Powder Sintered Parts in Shock Absorber Performance

Improving Shock Absorption Abilities

Real-Life Uses in Cars

Future of Powder Metallurgy in Shock Absorbers

The best sintered parts

we are Max Auto Parts ltd

Max Auto Parts ltd is China top 2 manufacturers in shock struts ,Shock absorber damper industrial .

The Sintered parts piston , base valve and rod guide play important role in shock absorber ,

It is not a secret that in the past some China factories not care about the quality , that caused many problem , in this situation , our factory by improve technical , changing the machines , the precision and quality have achieve the world top shock absorber manufacturer’s approve , like Bilstein , VW .

Now our factory have got the IATF TS16949 certificate .

FAQS

What are your prices?

Our pricing structure is designed to flexibly respond to market dynamics. Therefore, prices may be adjusted based on factors such as supply levels, demand fluctuations, and other economic conditions.

We understand that accurate pricing is critical to your planning and budgeting, so we encourage you to contact us directly. Once your company reaches out to us for more information, we will immediately provide you with a customized price list tailored to your specific needs.

Additionally, we are happy to discuss potential discounts for bulk orders or long-term partnerships. Your satisfaction is our top priority, and we look forward to collaborating with you to find the best solutions for your business.

Do you have a minimum order quantity?

Yes, we do have a minimum order quantity (MOQ) for all international orders. This varies depending on the product category, so we recommend that you contact us for details that suit your needs.

What is the average lead time?

Our average lead time for our products varies depending on the type of order. For sample requests, you can expect a lead time of approximately 7 days. This allows us to prepare and deliver representative samples of our products for your evaluation.

For production orders, lead times are typically 20 to 30 days after we receive your deposit payment. It is important to note that these lead times are only valid if both of the following conditions are met:

(1) We have received your deposit.

(2) We have received your final confirmation of the product specifications.

We understand that time is of the essence in your company’s operations. If our standard lead times do not match your project deadlines, we recommend that you discuss your specific needs with our sales team. MAX is committed to flexibility and support, and in most cases can adjust production plans to meet your needs. Your satisfaction is our top priority, and we will do our utmost to ensure that your order is delivered on time without sacrificing product quality.

What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance against the copy of B/L.

Does the product have warranty service

We warranty our materials and workmanship, reflecting our unwavering commitment to quality and customer satisfaction. Our warranty ensures that you can trust in the durability and reliability of our products, giving you peace of mind with every purchase.

However, our dedication to your satisfaction goes beyond just the warranty. Regardless of whether an issue falls under warranty or not, it is ingrained in our company culture to proactively address and resolve all customer concerns. We believe that every customer interaction is an opportunity to build lasting relationships, and we strive to ensure that every issue is handled promptly and effectively.

Our customer service team is always ready to assist you, whether you have questions about our products, need support with an order, or require assistance with a warranty claim. We value your feedback and are committed to making your experience with us as positive as possible. Your satisfaction is our top priority, and we are here to support you every step of the way.

How about the transportation cost?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.