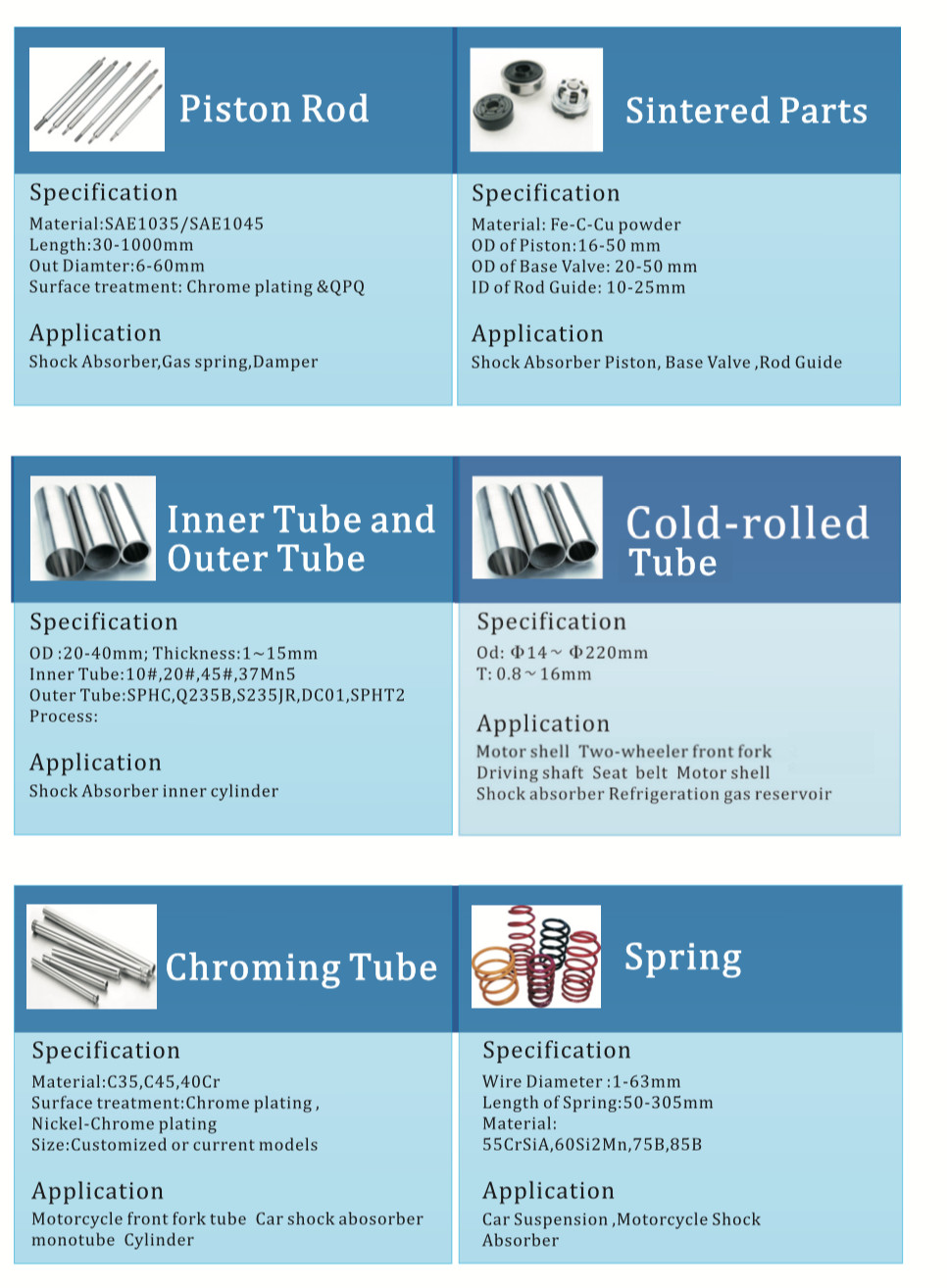

Product Use

To accelerate the attenuation of frame and body vibrations to improve the smoothness (comfort) of the car, shock absorbers are installed inside the suspension system in most cars.

The shock-absorbing system of a car is made up of springs and shock absorbers. Shock absorbers are not used to support the weight of the body, but are used to suppress the shock of spring bounce after shock absorption and to absorb the energy of road impact. Springs play a role in cushioning shocks, turning "large energy shock" into "small energy multiple impacts", while shock absorbers gradually reduce "small energy multiple shocks". If you drive a car whose shock absorber has broken down, you can experience the car bouncing through every hole and the after-effects of the ups and downs, which is used to suppress this bounce. Without the shock absorber, the spring's rebound will not be controlled, the car will produce serious bounce when it encounters rough road surfaces, and the loss of tire grip and traceability due to the shock of the spring up and down the bend.

Product Classification

Divided by material

From the angle of producing damping materials, shock absorbers are mainly hydraulic and inflatable, there is a variable damping damper.

Hydraulic

Hydraulic shock absorbers are widely used in automotive suspension systems. The principle is that when the frame and the axle move back and forth and the piston moves back and forth in the cylinder tubeof the shock absorber, the fluid in the shock absorber housing flows repeatedly through some narrow pores into the inner cavity. At this point, the friction between the liquid and the inner wall and the inner friction of the liquid molecule form a damping force on the vibration.

Inflatable ( Gas filling )

Inflatable shock absorbers are a new type of shock absorbers developed since the 1960s. The structure is characterized by a floating piston in the lower part of the cylinder barrel, which is filled with high-pressure nitrogen in an air-tight chamber formed at one end of the floating piston and cylinder An O-seal with a large section is mounted on the floating piston, which completely separates the oil from the gas. The working piston is fitted with compression and extension valves that change the channel cross-sectional area depending on the speed of movement. When the wheels bounce up and down, the shock absorber's working pistons do reciprocating motion in the fluid, causing a difference in oil pressure between the upper and lower cavities of the working pistons, and the pressure oil pushes the compression valve and the extension valve back and forth. Because the valve produces a large damping force on the pressure oil, the vibration decays.

Divided by structural

The structure of the shock absorber is a piston rod inserted into the tubewith pistons, which is filled with oil. The piston has throttle holes that allow the oil in the two parts of space separated by the piston to complement each other. Damping is produced when viscous oil passes through the throttle hole, the smaller the throttle hole, the greater the damping force, the greater the viscosity of the oil, the greater the damping force. If the throttle size does not change, when the shock absorber is operating fast, damping over-the-assembly effects on the absorption of shocks. Therefore, a disc-shaped reed valve is set at the outlet of the throttle hole, and when the pressure increases, the valve is opened to the top, the throttle hole opening is larger and the damping is reduced. Because the piston is in two-way motion, the reed valves are installed on both sides of the piston, called compression valves and extension valves, respectively.

According to its structure, the damper is divided into single and double barrels. It can be further divided into: 1. . Mono tube air pressure damper; Double-tube oil pressure damper; Twin tube oil and gas shock absorber

Twin tube

Refers to the shock absorber has two cylinders inside and outside, the piston in the inner cylinder movement, because of the piston rod into and out, the volume of oil in the inner cylinder increases and shrinks, so through the exchange with the outer tube to maintain the balance of oil in the inner barrel. Therefore, there should be four valves in the twin tube damper, that is, in addition to the two throttle valves on the piston mentioned above, there is also a circulation valve and compensation valve installed between the inner and outer cylinders to complete the exchange.

Mono tube

Compared with the binocular type, the mono tube damper is simple in structure and reduces the number of valve systems. It is fitted with a floating piston in the lower part of the cylinder tube( so-called floating means that there is no piston rod to control its motion )and forms an air chamber under the floating piston filled with high-pressure nitrogen. The change in liquid level caused by the piston rod entering and exiting the fluid mentioned above is automatically adapted by floating the floating piston. In addition to the two shock absorbers described above, there are resistance adjustable dampers. It changes the size of the throttle hole through external operation. The most recent car used an electronically controlled shock absorber as a standard device to detect driving status through sensors, and the computer calculated the optimum damping force, allowing the damping mechanism on the shock absorber to operate automatically.

The shock absorber made by Max Auto , include oil type and gas type , twintube and mono tube , it have been sold widely to all over the world , include USA , EUROPE , Africa , Mid-East ,South Asia and South America .

Recent years Max developed a series of modified shock absorber , damping adjustable ,with monotube , also called coilover we are proud of got good rating on the world , we made OEM for some famous brand .

Post time: Sep-26-2021