China Wholesale Alloy Rim Factories - China top factory of Shock absorber powder sintered Parts ( piston , base valve , rod guide ) for car and motorcycle – Max

China Wholesale Alloy Rim Factories - China top factory of Shock absorber powder sintered Parts ( piston , base valve , rod guide ) for car and motorcycle – Max Detail:

Sintered part factory

Max Auto Parts ltd is China top 2 manufacturers in shock struts ,Shock absorber damper industrial .

The Sintered parts piston , base valve and rod guide play important role in shock absorber ,

It is not a secret that in the past some China factories not care about the quality , that caused many problem , in this situation , our factory by improve technical , changing the machines , the precision and quality have achieve the world top shock absorber manufacturer’s approve , like Bilstein , VW .

Now our factory have got the IATF TS16949 certificate .

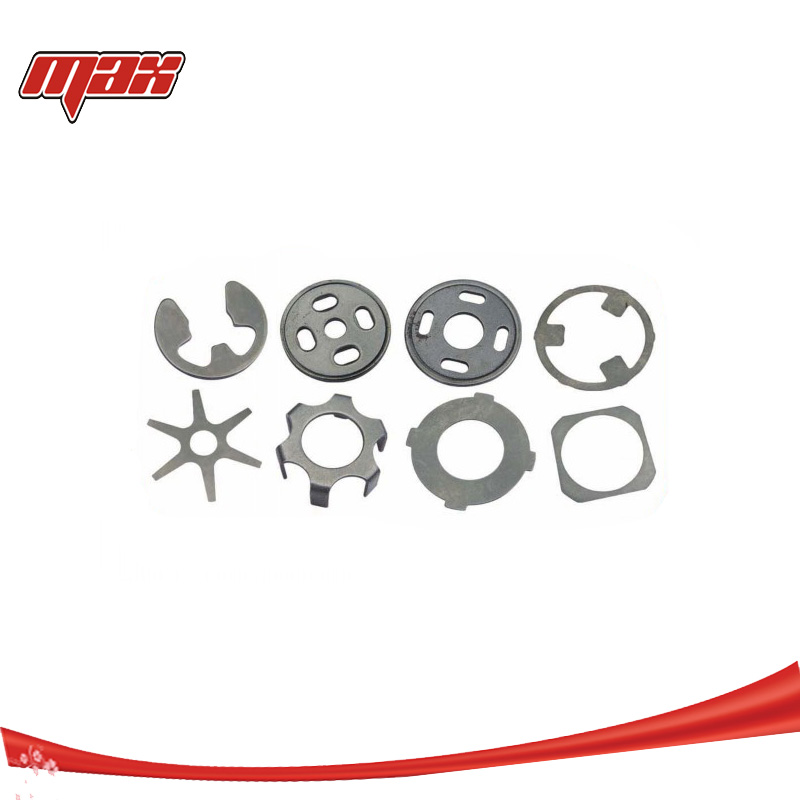

1.Piston, bottom valve, rod guide made by powder metallurgy technology.Using fe-c-cu powder, the mould is pressed, sintered and machined.

2.Product features:

The piston and the bottom valve mainly provide damping for the shock absorber ,rod guide mainly guide for the movement of piston rod.

Technological process: mixing powder – forming – sintering – cleaning -Steam treatment – Bending-Press bushing-Appearance inspection, packing

Mixing powder: Fe – C – Cu powder by high density sieve to remove impurities, automatic blending machine 360 ° rotating more than 4 hours, make the material mix evenly

Molding: precision mould with automatic CNC hydraulic press to ensure the density of all parts meet the process requirements after pressing.

Sintering: the product is controlled by the net belt type sintering furnace, which ensures the mechanical properties and hardness of the products to meet the technical requirements.

Oil immersion: place the product in a high pressure vessel so that the oil can fully penetrate into the product’s pores and avoid the rust of the later cycle.

Plastic: precision mould with full automatic CNC hydraulic press, the product density and mechanical properties are further improved after pressing, and the dimensions meet the requirements of the drawing.

Machining: finish the hole, groove and other details of the product.

Cleaning: the mesh belt adopts ultrasonic cleaning machine to remove impurities and iron filings.

Steam treatment: the product is treated by steam in the electric furnace, which improves the mechanical properties of the product, and the surface oxidation layer helps to prevent rust.

Packing: the piston is covered by a fully automatic numerical control machine covering the PTFE lubrication belt.

Press bushing: pressed into DU bushing.

Appearance inspection, packing.

3.Specification :

|

Product Details |

|

| Product Name | Powder Metal Sintered Part for Shock Absorber |

| Material | (MPIF 35) FC-0205 (DIN 30910-4) Sint C10, Fe, Balance, Cu 1.5-3.9%, C 0.3-0.6% |

| Density | 6.4-6.9 g/cm3 after steam oxidation |

| Hardness | 60-115 HRB, loading 1 kN, diameter of ball 1/16″ |

| Surface Treatment | Steam oxidation, 2 hours, Fe3O4: 0.004-0.005mm, degree of oxidation 2-4% |

| Unspecified Tolerance | ISO 2768 – m / H14, h14, +- IT14/2 |

| Apperance | No crumbling, cracks, exfoliation, voids, looseness, metal pitting and other defects |

| Process Flow | Powder mixing – Forming – Sintering – Oil impregnation – Sizing - Ultrasonic cleaning – Steam oxidation – Oil impregnation – Final inspection – (+ DP4 bushing / +PTFE band) Packing |

| Application | For automobile, motorcycle and bicycle shock absorber |

|

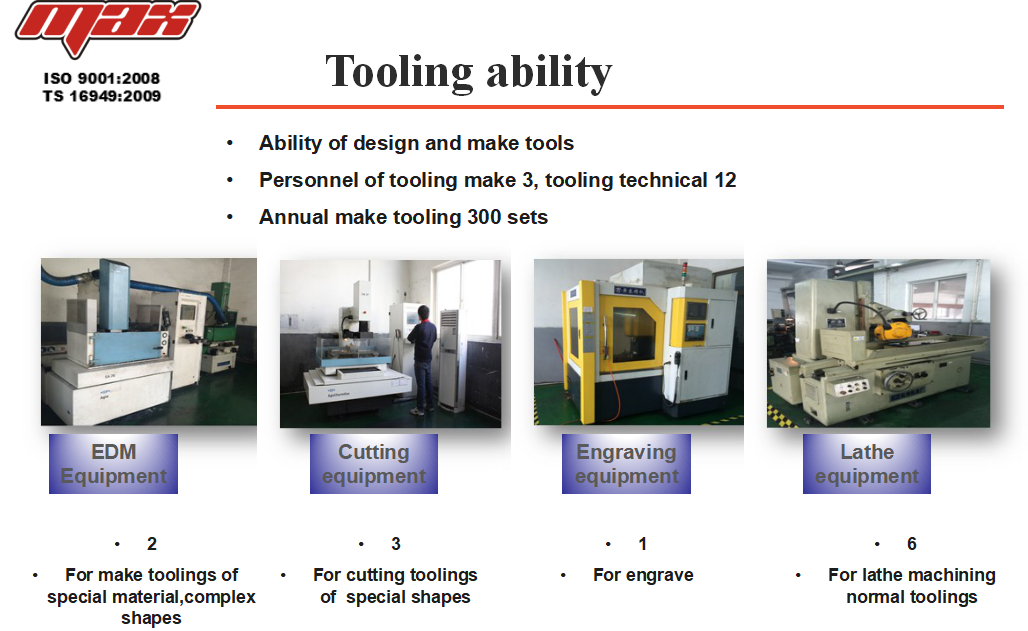

Our Advantages: |

1. More than current 3000 moulds ,save your mold cost 2. ISO/TS 16949:2009 certificate 3.Competitive price 4.Strictly quality control capacity of APQP、FEMA、MSA、PPAP、SPC |

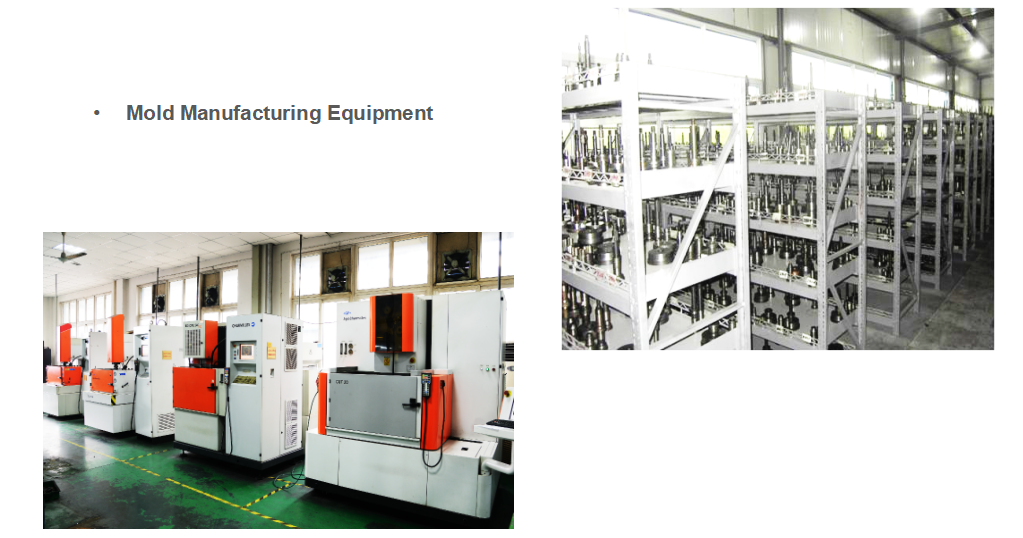

4.Production Facilities

Examination Facilities

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for China Wholesale Alloy Rim Factories - China top factory of Shock absorber powder sintered Parts ( piston , base valve , rod guide ) for car and motorcycle – Max , The product will supply to all over the world, such as: Mumbai, Tajikistan, Israel, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.