China Wholesale Tube Manufacturers - Chinna factory of shock absorber powder Metallurgy parts piston , base valve , rod guide – Max

China Wholesale Tube Manufacturers - Chinna factory of shock absorber powder Metallurgy parts piston , base valve , rod guide – Max Detail:

Max Auto Parts ltd is China top 2 manufacturers in Shock absorber , shock struts industrial .

The Sintered parts piston , base valve and rod guide play important role in shock absorber ,

It is not a secret that in the past some China factories not care about the quality , that caused many problem , in this situation , our factory by improve technical , changing the machines , the precision and quality have achieve the world top shock absorber manufacturer’s approve , like Bilstein , VW .

Now our factory have got the IATF TS16949 certificate .

Our factory located in China , Ningbo City .

Here is some video of our factory production line .

1.Piston, bottom valve, rod guide made by powder metallurgy technology.Using fe-c-cu powder, the mould is pressed, sintered and machined.

2.Product features:

The piston and the bottom valve mainly provide damping for the shock absorber ,rod guide mainly guide for the movement of piston rod.

Technological process: mixing powder – forming – sintering – cleaning -Steam treatment – Bending-Press bushing-Appearance inspection, packing

Mixing powder: Fe – C – Cu powder by high density sieve to remove impurities, automatic blending machine 360 ° rotating more than 4 hours, make the material mix evenly

Molding: precision mould with automatic CNC hydraulic press to ensure the density of all parts meet the process requirements after pressing.

Sintering: the product is controlled by the net belt type sintering furnace, which ensures the mechanical properties and hardness of the products to meet the technical requirements.

Oil immersion: place the product in a high pressure vessel so that the oil can fully penetrate into the product’s pores and avoid the rust of the later cycle.

Plastic: precision mould with full automatic CNC hydraulic press, the product density and mechanical properties are further improved after pressing, and the dimensions meet the requirements of the drawing.

Machining: finish the hole, groove and other details of the product.

Cleaning: the mesh belt adopts ultrasonic cleaning machine to remove impurities and iron filings.

Steam treatment: the product is treated by steam in the electric furnace, which improves the mechanical properties of the product, and the surface oxidation layer helps to prevent rust.

Packing: the piston is covered by a fully automatic numerical control machine covering the PTFE lubrication belt.

Press bushing: pressed into DU bushing.

Appearance inspection, packing.

3.Specification :

|

Product Details |

|

| Product Name | Powder Metal Sintered Part for Shock Absorber |

| Material | (MPIF 35) FC-0205 (DIN 30910-4) Sint C10, Fe, Balance, Cu 1.5-3.9%, C 0.3-0.6% |

| Density | 6.4-6.9 g/cm3 after steam oxidation |

| Hardness | 60-115 HRB, loading 1 kN, diameter of ball 1/16″ |

| Surface Treatment | Steam oxidation, 2 hours, Fe3O4: 0.004-0.005mm, degree of oxidation 2-4% |

| Unspecified Tolerance | ISO 2768 – m / H14, h14, +- IT14/2 |

| Apperance | No crumbling, cracks, exfoliation, voids, looseness, metal pitting and other defects |

| Process Flow | Powder mixing – Forming – Sintering – Oil impregnation – Sizing - Ultrasonic cleaning – Steam oxidation – Oil impregnation – Final inspection – (+ DP4 bushing / +PTFE band) Packing |

| Application | For automobile, motorcycle and bicycle shock absorber |

|

Our Advantages: |

1. More than current 3000 moulds ,save your mold cost 2. ISO/TS 16949:2009 certificate 3.Competitive price 4.Strictly quality control capacity of APQP、FEMA、MSA、PPAP、SPC |

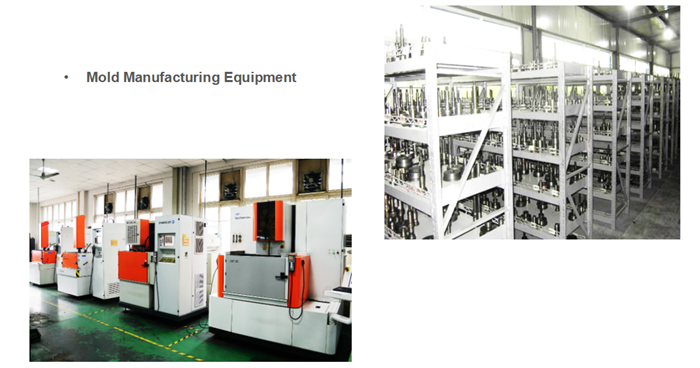

4.Production Facilities

模具设备

Examination Facilities

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for China Wholesale Tube Manufacturers - Chinna factory of shock absorber powder Metallurgy parts piston , base valve , rod guide – Max , The product will supply to all over the world, such as: South Africa, Mexico, Sydney, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.