Choosing the Right Motorcycle Suspension Shims for Your Bike

Select the right motorcycle suspension shims by matching diameter to your piston and thickness to your damping needs. Spring steel offers durability for most riders.

Select the right motorcycle suspension shims by matching diameter to your piston and thickness to your damping needs. Spring steel offers durability for most riders.

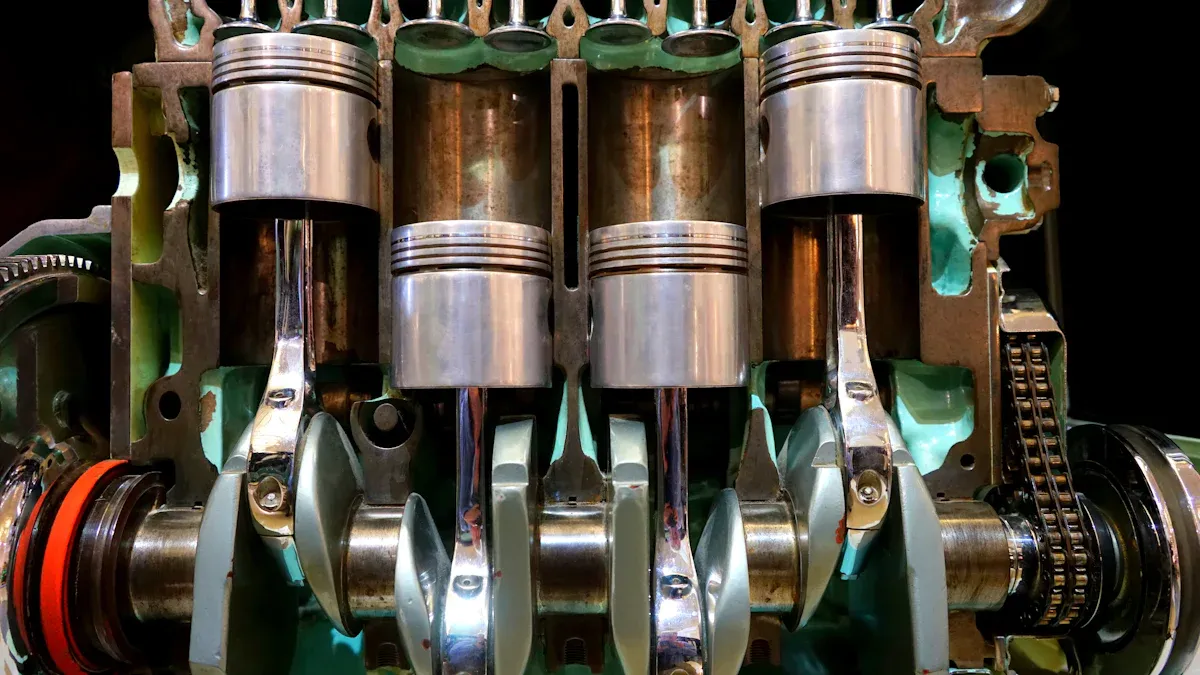

Common synonyms for piston rod include connecting rod, piston shaft, and plunger shaft. Each term refers to similar parts but may vary by application.

Upgrading your shock absorber piston to a high-flow design improves damping, reduces harshness, and gives you more control for off-road or street driving.

A hydraulic cylinder piston rod connects the piston to machinery, transmitting force and motion for lifting, pushing, or pulling heavy loads efficiently.

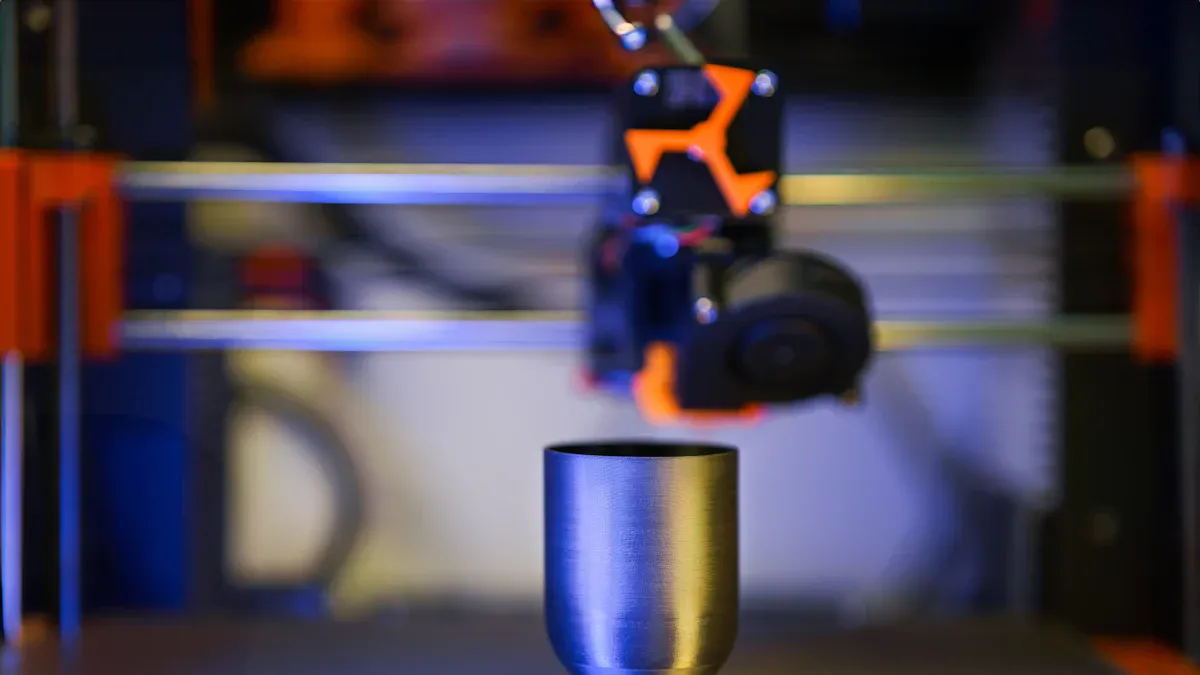

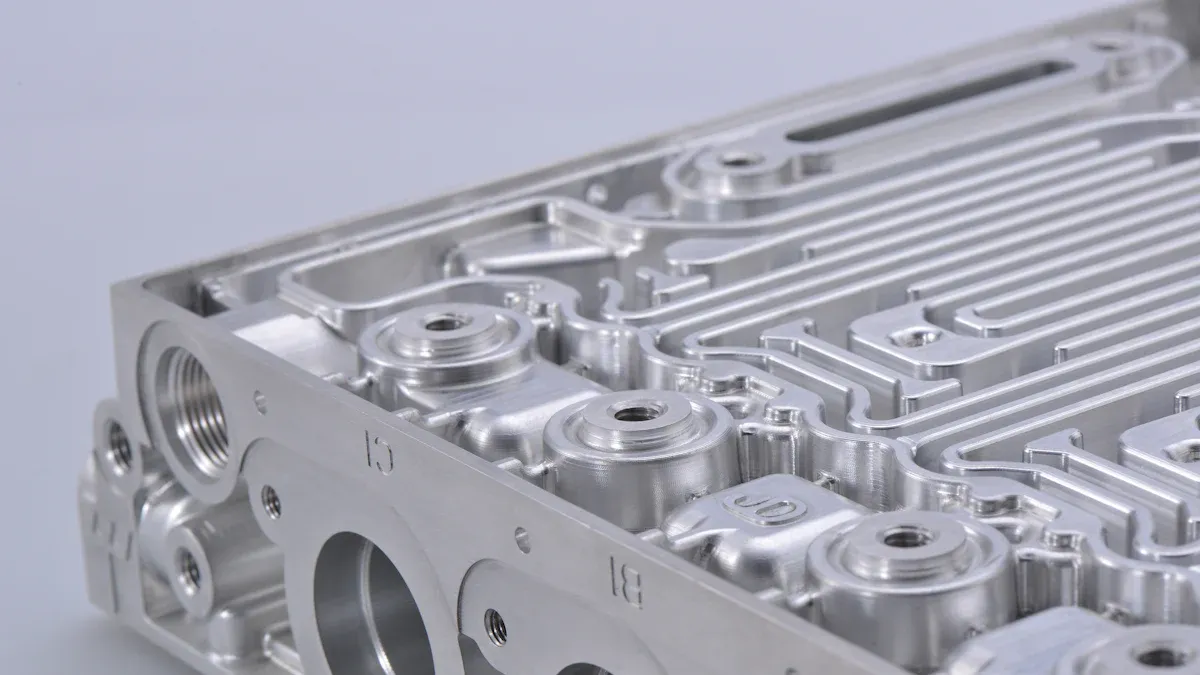

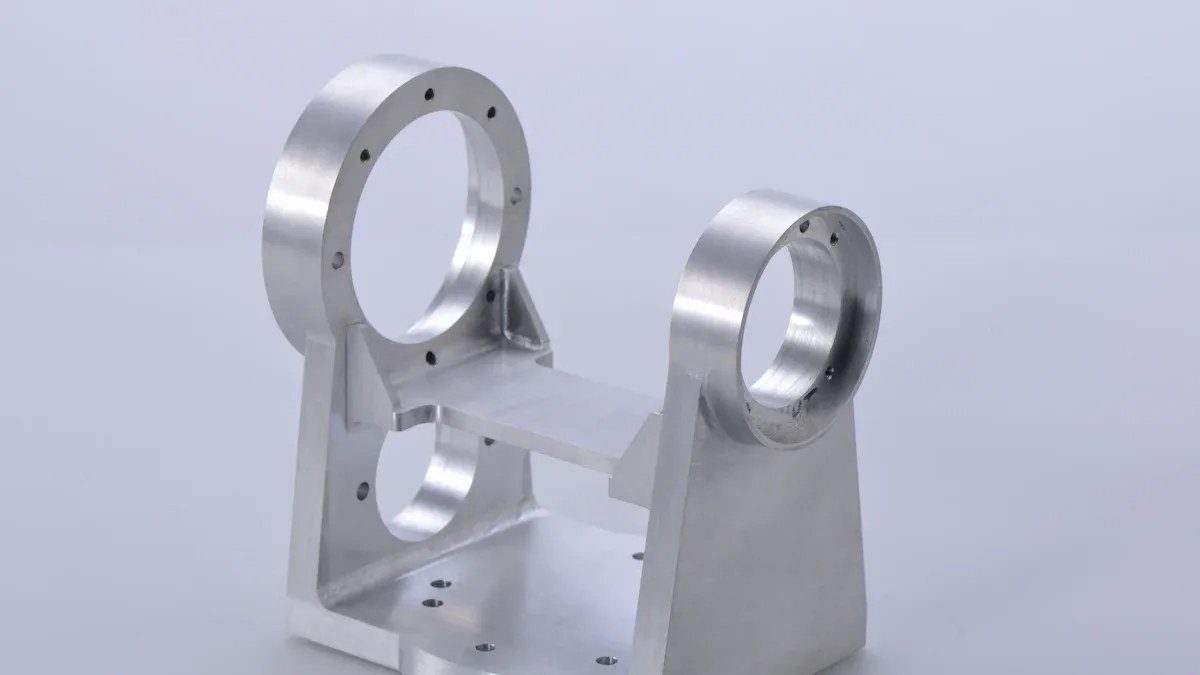

The process in powder metallurgy offers key advantages like superior material utilization, unmatched design flexibility, and cost-effectiveness for high-volume parts.

Suspension valving shims are thin steel discs in your shocks that control damping. Their thickness, diameter, and stack arrangement dictate handling and ride quality.

A shock absorber piston rod connects suspension parts, controls movement, and improves ride comfort and safety by reducing bumps and vibrations.

Select the right precision powdered metal parts by matching your design complexity, performance needs, and volume to the ideal process, from MIM to conventional PM.

Shock valving shims precisely control oil flow in your suspension to manage compression and rebound. This action creates damping force for a smoother ride and better handling.

Parts produced by powder metallurgy offer superior strength, complex net-shape designs, and reduced weight, enhancing engine performance and fuel efficiency.

INFORMATION

CONTACT