News

-

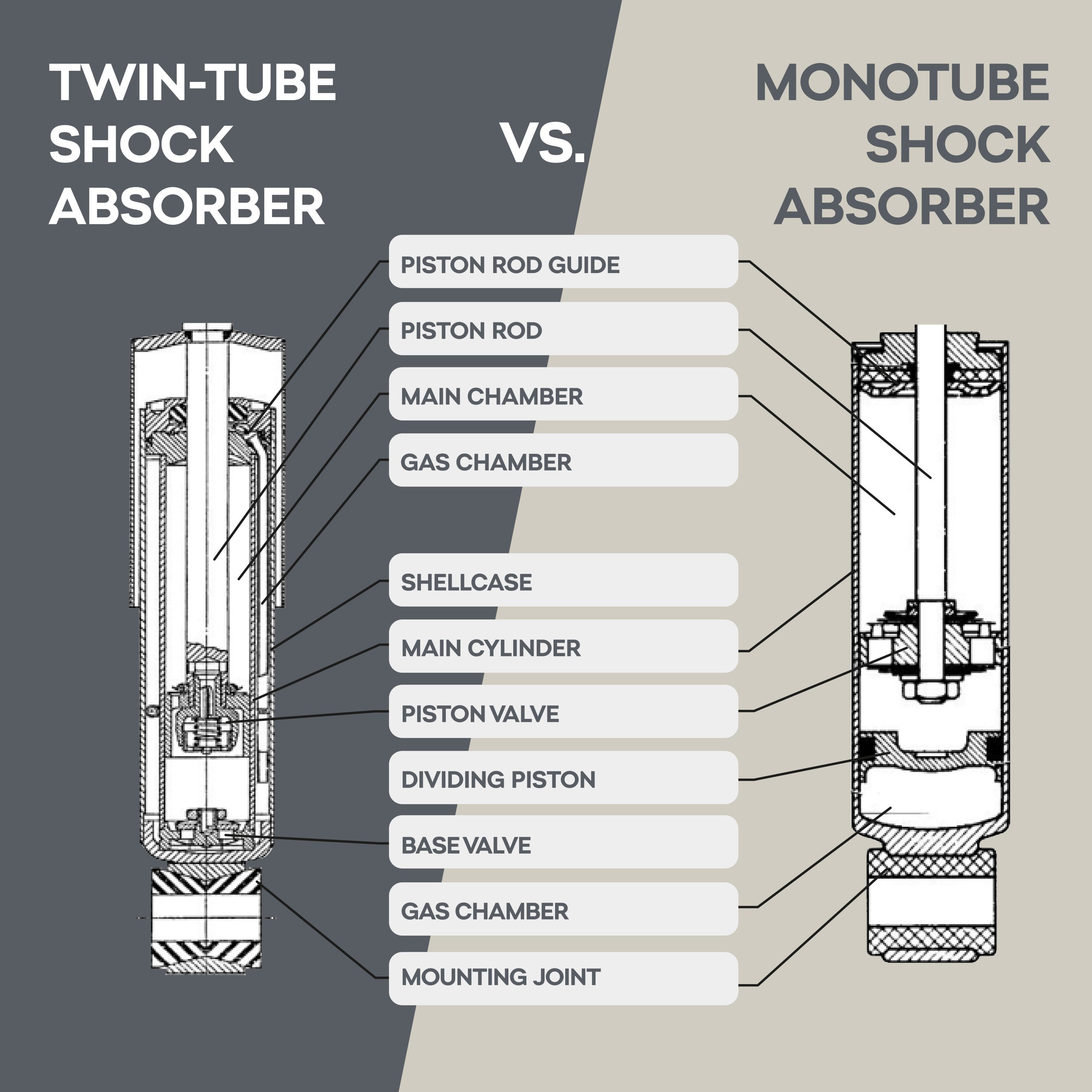

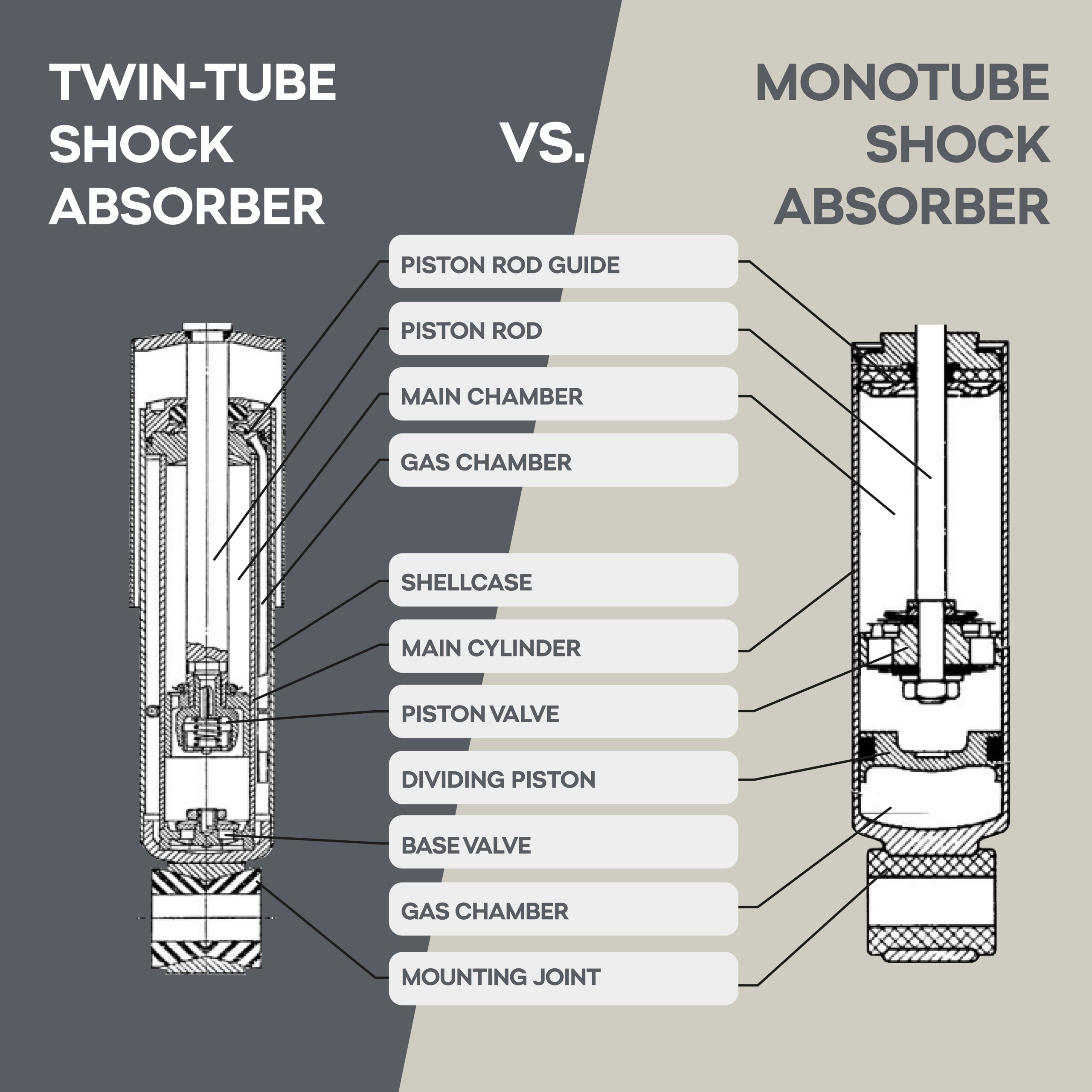

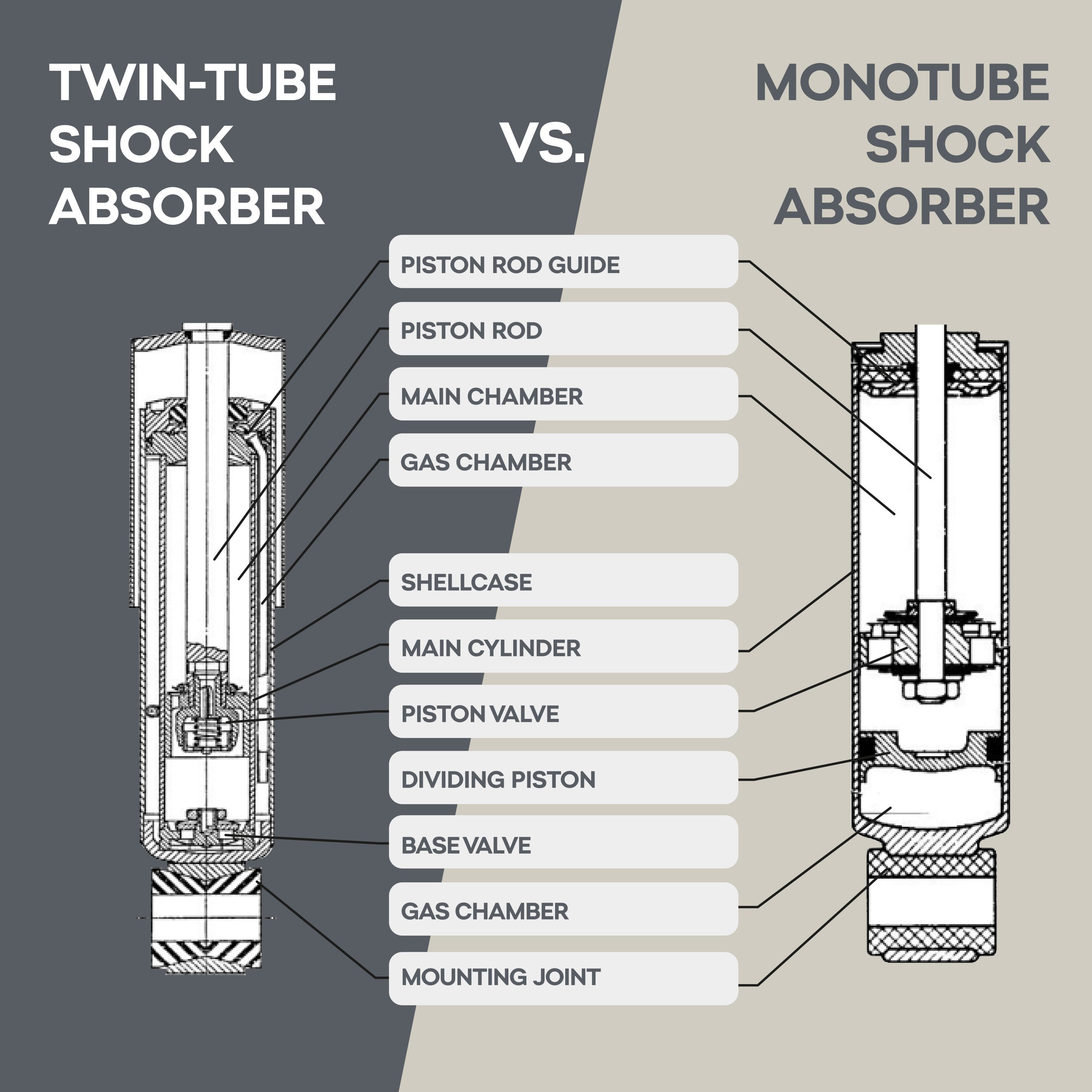

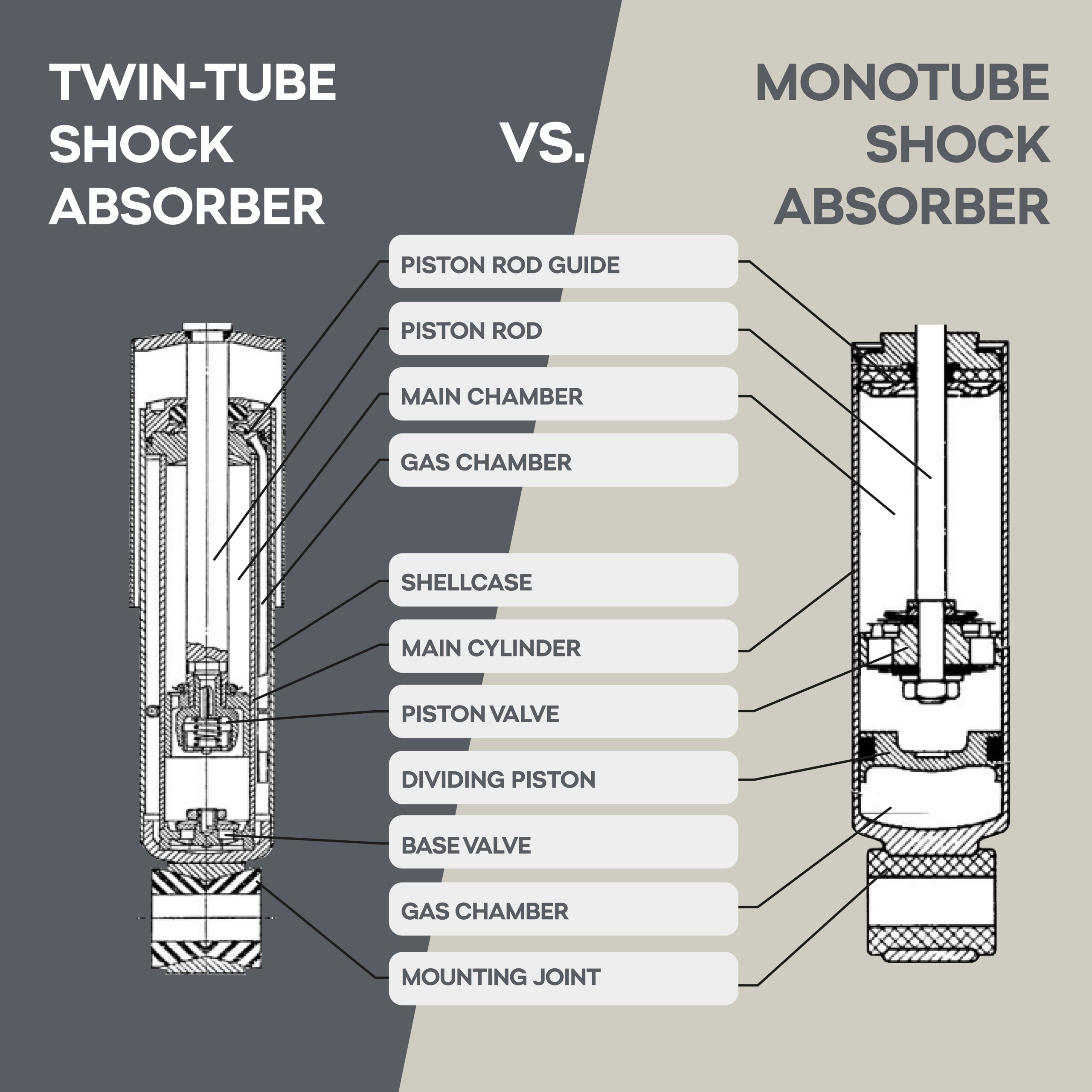

Which parts are the suspension made up of

Automobile suspension is an elastic device connecting frame and axle in automobile. It is generally composed of elastic components, guide mechanism, shock absorber and other components, the main task is to ease the impact from uneven road to the frame, in order to improve the comfort of the ride:...Read more -

When Shock absorber is broken what symptoms will be

Automobile shock absorber damage, the most obvious phenomenon is the car in the process of running jump, brake will appear abnormal sound. Auto shock absorber is in order to protect the body and frame, the car driving process, reduce the vibration of the body and frame to produce, so as t...Read more -

Complete Shock Strut structure

Complete Shock Strut is composed of shock absorber, lower spring pad, dust jacket, spring, shock absorber pad, upper spring pad, spring seat, bearing, top glue and nut. Complete Shock Strut uses fluid to convert the elastic energy of the spring into heat energy to make the vehicle movemen...Read more -

Shock abosorber powder metallurgy accessories /Max Auto Parts

Shock abosorber powder metallurgy accessories 1.Product performance Through sintered parts, it can meet the structural requirements of various shock absorbers. At the same time, reasonable metal powder mixing is used to make its wear resistance and corrosion resistance stronger, and the internal...Read more -

Dragon Boat Festival Holidays from June 3rd to June 5th

Historical origin “Dragon Boat Festival” “end” the original meaning of the word “is”, “noon” for “. “Dragon Boat Festival” (Dragon Boat Five), “zhongzheng” also, the noon is in the middle of the. The ancient people to...Read more -

What is best brand for oil seal in shock absorber industrial

What is best brand for oil seal in shock absorber industrial Best Choice for shock absorber oil seal factory . What is an oil seal? Oil seal is the customary name for general seals, which is simply the seal of lubricating oil. Oil seals are generally divided into single type and assembly t...Read more -

Shock absorber — Guarantee the stability of your car

How does shock absorber / shock struts Guarantee the stability of your car Concept: The shock absorber is used to suppress the shock and the impact from the road surface when the spring rebounds after shock absorption. Widely used in automobiles, in order to accelerate the attenuation of the v...Read more -

Piston Rod—An important part of the shock absorber

piston composition: Piston components include: pistons, piston rings, support rings, piston rods, etc. According to different structural forms, pistons can be divided into cylindrical pistons (the length is larger than the diameter), disc pistons (the length is smaller than the diameter)...Read more -

Knowledge of shock absorber daily maintenance (how to maintain shock absorber )

Knowledge of shock absorber daily maintenance In order to make the vibration of the frame and body decay quickly, improve the ride comfort and comfort of the car, the automobile suspension system is generally equipped with shock absorbers. Shock absorbers are vulnerable parts in the process of a...Read more -

Multi-link independent suspension ( learning about shock absorber)

Multi-link independent suspension is composed of connecting rod, shock absorber and shock absorber spring. It has more links than the general suspension, according to the convention, generally put 4 links or more links structure of the suspension, known as the multi-link. Functional char...Read more -

How to inquiry to Chinese factories ?

An importer asked me what he should do when Chinese factories ask for his “price targets”. I think it is a legitimate question from factories Here is the sequence I advise importers to follow, when they source new suppliers: Get in touch with at least 3 potential suppliers, and ask some ...Read more -

The advantages of Mcpherson independent suspension

Mcphersonindependent suspension is an important part of the safety structure of the car. For a long time, the driving control and comfort of the car are closely related to the suspension system in the chassis structure, and the simplicity and complexity of the suspension structure also directly d...Read more